PDF Publication Title:

Text from PDF Page: 085

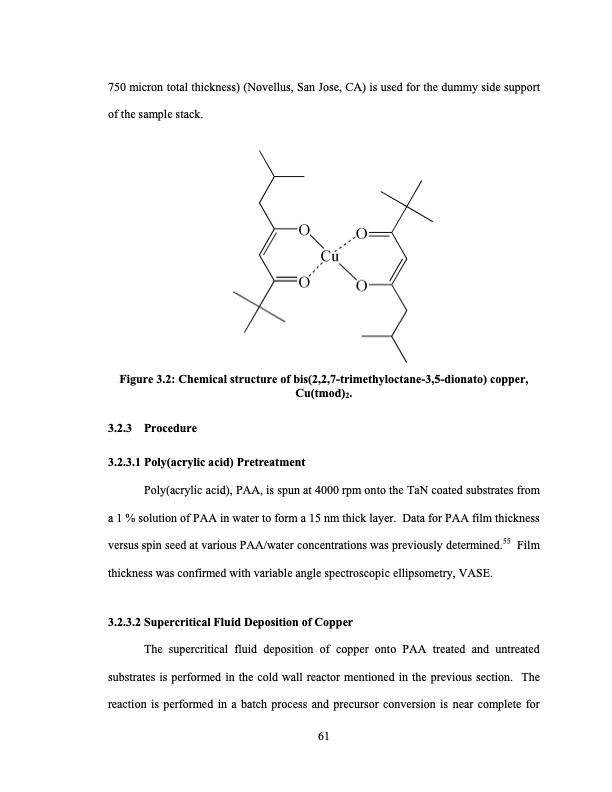

750 micron total thickness) (Novellus, San Jose, CA) is used for the dummy side support of the sample stack. Figure 3.2: Chemical structure of bis(2,2,7-trimethyloctane-3,5-dionato) copper, Cu(tmod)2. 3.2.3 Procedure 3.2.3.1 Poly(acrylic acid) Pretreatment Poly(acrylic acid), PAA, is spun at 4000 rpm onto the TaN coated substrates from a 1 % solution of PAA in water to form a 15 nm thick layer. Data for PAA film thickness versus spin seed at various PAA/water concentrations was previously determined.55 Film thickness was confirmed with variable angle spectroscopic ellipsometry, VASE. 3.2.3.2 Supercritical Fluid Deposition of Copper The supercritical fluid deposition of copper onto PAA treated and untreated substrates is performed in the cold wall reactor mentioned in the previous section. The reaction is performed in a batch process and precursor conversion is near complete for 61PDF Image | Supercritical Fluid Deposition Of Thin Metal Films

PDF Search Title:

Supercritical Fluid Deposition Of Thin Metal FilmsOriginal File Name Searched:

Supercritical-Fluid-Deposition-Of-Thin-Metal-Films-Kinetics-Mec.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |