PDF Publication Title:

Text from PDF Page: 093

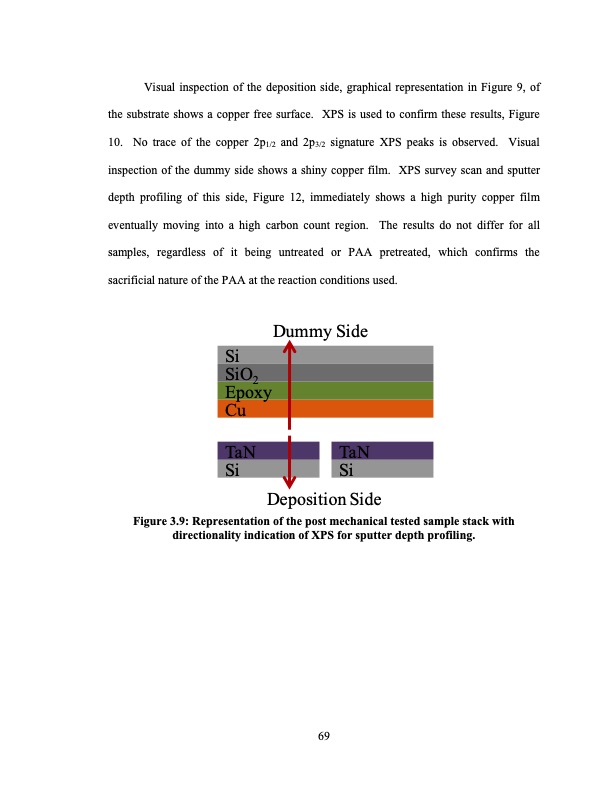

Visual inspection of the deposition side, graphical representation in Figure 9, of the substrate shows a copper free surface. XPS is used to confirm these results, Figure 10. No trace of the copper 2p1/2 and 2p3/2 signature XPS peaks is observed. Visual inspection of the dummy side shows a shiny copper film. XPS survey scan and sputter depth profiling of this side, Figure 12, immediately shows a high purity copper film eventually moving into a high carbon count region. The results do not differ for all samples, regardless of it being untreated or PAA pretreated, which confirms the sacrificial nature of the PAA at the reaction conditions used. Dummy Side Si SiO2 Epoxy Cu TaN Si TaN Si Deposition Side Figure 3.9: Representation of the post mechanical tested sample stack with directionality indication of XPS for sputter depth profiling. 69PDF Image | Supercritical Fluid Deposition Of Thin Metal Films

PDF Search Title:

Supercritical Fluid Deposition Of Thin Metal FilmsOriginal File Name Searched:

Supercritical-Fluid-Deposition-Of-Thin-Metal-Films-Kinetics-Mec.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |