PDF Publication Title:

Text from PDF Page: 181

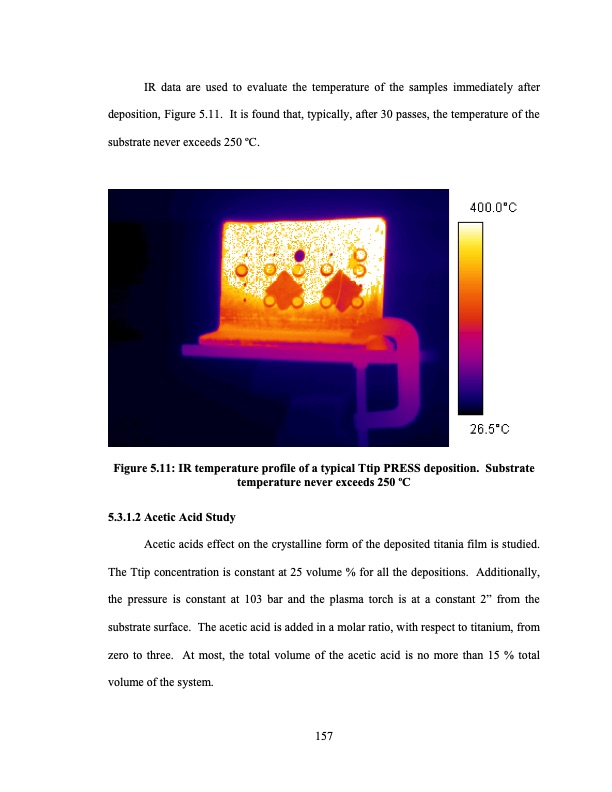

IR data are used to evaluate the temperature of the samples immediately after deposition, Figure 5.11. It is found that, typically, after 30 passes, the temperature of the substrate never exceeds 250 oC. Figure 5.11: IR temperature profile of a typical Ttip PRESS deposition. Substrate temperature never exceeds 250 oC 5.3.1.2 Acetic Acid Study Acetic acids effect on the crystalline form of the deposited titania film is studied. The Ttip concentration is constant at 25 volume % for all the depositions. Additionally, the pressure is constant at 103 bar and the plasma torch is at a constant 2” from the substrate surface. The acetic acid is added in a molar ratio, with respect to titanium, from zero to three. At most, the total volume of the acetic acid is no more than 15 % total volume of the system. 157PDF Image | Supercritical Fluid Deposition Of Thin Metal Films

PDF Search Title:

Supercritical Fluid Deposition Of Thin Metal FilmsOriginal File Name Searched:

Supercritical-Fluid-Deposition-Of-Thin-Metal-Films-Kinetics-Mec.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |