PDF Publication Title:

Text from PDF Page: 016

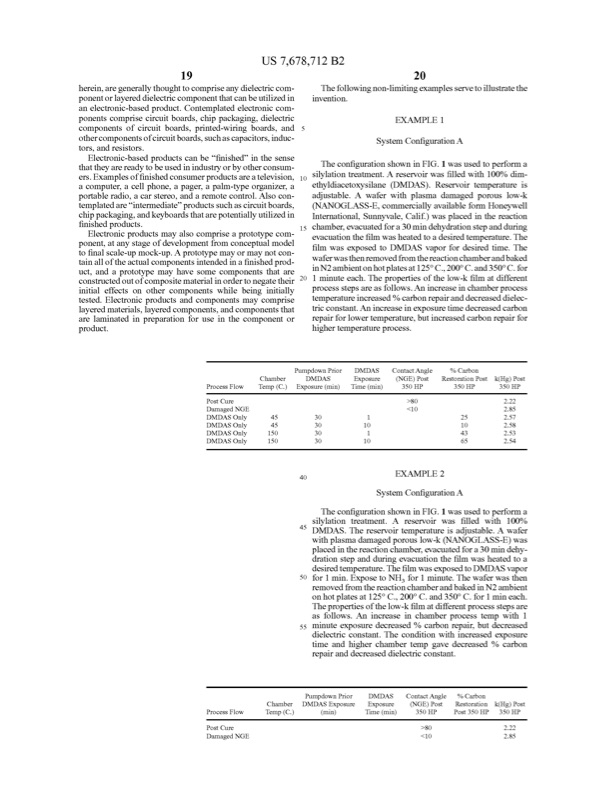

US 7,678,712B2 herein,aregeneralythoughttocompriseanydielectriccom Thefollowingnon-limitingexamplesservetoilustratethe 19 ponentorlayereddielectriccomponentthatcanbeutilizedin anelectronic-basedproduct.Contemplatedelectroniccom ponentscomprisecircuitboards,chippackaging,dielectric componentsofcircuitboards,printed-wiringboards,and othercomponentsofcircuitboards,suchascapacitors,induc tors,andresistors. Electronic-basedproductscanbe“finished inthesense thattheyarereadytobeusedinindustryorbyotherconsum ers.Examplesoffinishedconsumerproductsareatelevision,10 acomputer,acelphone,apager,apalm-typeorganizer,a portableradio,acarstereo,andaremotecontrol.Alsocon templatedare“intermediate'productssuchascircuitboards, chippackaging,andkeyboardsthatarepotentialyutilizedin finishedproducts. invention. 20 EXAMPLE 1. SystemConfigurationA Electronicproductsmayalsocompriseaprototypecom ponent,atanystageofdevelopmentfromconceptualmodel tofinalscale-upmock-up.Aprototypemayormaynotcon tainaloftheactualcomponentsintendedinafinishedprod uct,andaprototypemayhavesomecomponentsthatare constructedoutofcompositematerialinordertonegatetheir initialefectson othercomponents while being initialy tested.Electronicproductsandcomponentsmaycomprise layeredmaterials,layeredcomponents,andcomponentsthat arelaminatedinpreparationforuseinthecomponentor product. 15 TheconfigurationshowninFIG.1wasusedtoperforma silylationtreatment.Areservoirwasfiledwith100%dim ethyldiacetoxysilane(DMDAS).Reservoirtemperatureis adjustable.A waferwithplasmadamagedporouslow-k (NANOGLASS-E,commerciallyavailableformHoneywell International,Sunnyvale,Calif.)wasplacedinthereaction chamber,evacuatedfora30mindehydrationstepandduring evacuationthefilmwasheatedtoadesiredtemperature.The filmwasexposedtoDMDAS vaporfordesiredtime.The waferwasthenremovedfromthereactionchamberandbaked inN2ambientonhotplatesat125°C.,200°C.and350°C.for 1minuteeach.Thepropertiesofthelow-kfilmatdiferent processstepsareasfolows.Anincreaseinchamberprocess temperatureincreased96carbonrepairanddecreaseddielec tricconstant.Anincreaseinexposuretimedecreasedcarbon repairforlowertemperature,butincreasedcarbonrepairfor highertemperatureproces. Chamber ProcessFlow Temp(C.) PostCure DamagedNGE DMDAS Only 45 DMDAS Only 45 DMDAS Only 150 DMDAS Only 150 PumpdownPrior DMDAS DMDAS ContactAngle % Carbon Exposure (NGE)Post RestorationPost k(Hg)Post Exposure(min) Time(min) 30 1 30 10 30 1 30 10 350 HP 350 HP 25 10 43 65 350 HP 2.22 2.85 2.57 2.58 2.53 2.54 40 45 50 55 EXAMPLE 2 SystemConfigurationA TheconfigurationshowninFIG.1wasusedtoperforma silylationtreatment.A reservoirwasfiledwith100% DMDAS.Thereservoirtemperatureisadjustable.Awafer withplasmadamagedporouslow-k(NANOGLASS-E)was placedinthereactionchamber,evacuatedfora30mindehy drationstepandduringevacuationthefilmwasheatedtoa desiredtemperature.ThefilmwasexposedtoDMDASvapor for1min.ExposetoNH for1minute.Thewaferwasthen removedfromthereactionchamberandbakedinN2 ambient onhotplatesat125°C.,200°C.and350°C.for1mineach. Thepropertiesofthelow-kfilmatdiferentprocessstepsare asfolows.An increaseinchamberprocesstempwith1 minuteexposuredecreased'%carbonrepair,butdecreased dielectricconstant.Theconditionwithincreasedexposure timeandhigherchambertempgavedecreased'%carbon repairanddecreaseddielectricconstant. PumpdownPrior DMDAS ContactAngle %Carbon DMDASExposure Exposure (NGE)Post Restoration k(Hg)Post Chamber ProcessFlow Temp(C.) (min) Time(min) 350HP Post350HP 350HP PostCure >80 2.22 DamagedNGE <10 2.85PDF Image | VAPOR PHASE TREATMENT OF DELECTRIC MATERALS

PDF Search Title:

VAPOR PHASE TREATMENT OF DELECTRIC MATERALSOriginal File Name Searched:

US7678712.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |