PDF Publication Title:

Text from PDF Page: 017

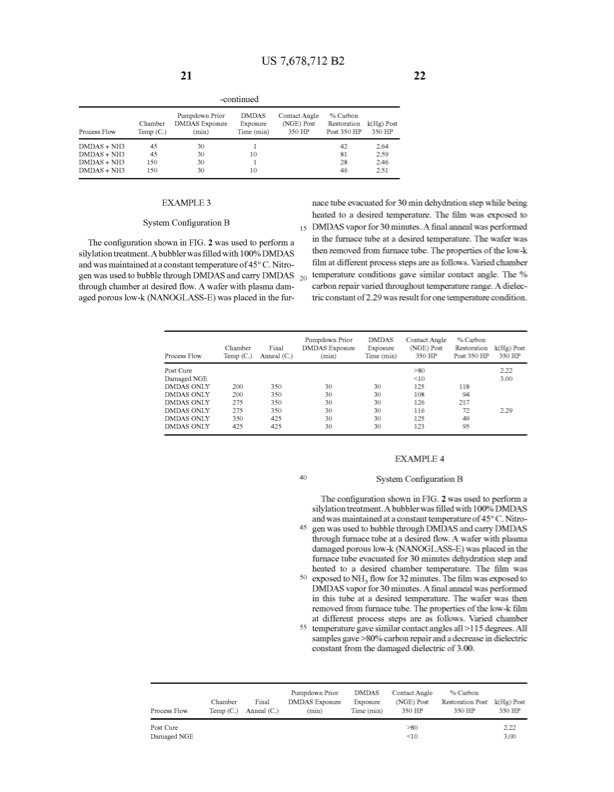

-continued PumpdownPrior DMDAS ContactAngle %Carbon Chamber DMDASExposure Exposure (NGE)Post Restoration k(Hg)Post ProcessFlow Temp(C.) (min) Time(min) 350HP Post350HP 350HP DMDAS - NH3 DMDAS - NH3 DMDAS - NH3 DMDAS - NH3 45 30 45 30 150 30 150 30 EXAMPLE3 SystemConfigurationB 1 10 1 10 42 2.64 81 2.59 28 2.46 46 2.51 nacetubeevacuatedfor30mindehydrationstepwhilebeing heatedtoadesiredtemperature.Thefilmwasexposedto DMDASvaporfor30minutes.Afinalannealwasperformed inthefurnacetubeatadesiredtemperature.Thewaferwas thenremovedfromfurnacetube.Thepropertiesofthelow-k filmatdiferentprocessstepsareasfolows.Variedchamber temperatureconditionsgavesimilarcontactangle.The% carbonrepairvariedthroughouttemperaturerange.Adielec tricconstantof2.29wasresultforonetemperaturecondition. US 7,678,712B2 TheconfigurationshowninFIG.2wasusedtoperforma silylationtreatment.Abubblerwasfiledwith100%DMDAS andwasmaintainedataconstanttemperatureof45°C.Nitro genwasusedtobubblethroughDMDASandcaryDMDAS throughchamberatdesiredflow.Awaferwithplasmadam agedporouslow-k(NANOGLASS-E)wasplacedinthefur Chamber Final ProcessFlow Temp(C.)Anneal(C.) (min) Time(min) 350HP Post350HP 350HP PostCure DamagedNGE DMDAS ONLY 200 350 DMDAS ONLY 200 350 DMDAS ONLY 275 350 DMDAS ONLY 275 350 DMDAS ONLY 350 425 DMDAS ONLY 425 425 >80 2.22 <10 3.00 30 30 125 118 30 30 108 94 30 30 126 217 30 30 116 72 2.29 30 30 125 49 30 30 123 95 EXAMPLE 4 SystemConfigurationB ProcessFlow PostCure DamagedNGE Chamber Final Temp(C.) Anneal(C.) PumpdownPrior DMDAS Exposure (min) DMDAS Exposure Time(min) ContactAngle (NGE)Post 350HP >80 <10 % Carbon Restoration Post 350HP k(Hg)Post 350HP 2.22 3.00 15 40 45 50 55 TheconfigurationshowninFIG.2wasusedtoperforma silylationtreatment.Abubblerwasfiledwith100%DMDAS andwasmaintainedataconstanttemperatureof45°C.Nitro genwasusedtobubblethroughDMDASandcaryDMDAS throughfurnacetubeatadesiredflow.A waferwithplasma damagedporouslow-k(NANOGLASS-E)wasplacedinthe furnacetubeevacuatedfor30minutesdehydrationstepand heated to a desired chamber temperature. The film was exposedtoNH,flowfor32minutes.Thefilmwasexposedto DMDASvaporfor30minutes.Afinalannealwasperformed inthistubeatadesiredtemperature.Thewaferwasthen removedfromfurnacetube.Thepropertiesofthelow-kfilm atdiferentprocessstepsareasfolows.Variedchamber temperaturegavesimilarcontactanglesal>115degres.All samplesgave>80%carbonrepairandadecreaseindielectric constantfromthedamageddielectricof3.0. PumpdownPrior DMDAS ContactAngle % Carbon DMDASExposure Exposure (NGE)Post Restoration k(Hg)PostPDF Image | VAPOR PHASE TREATMENT OF DELECTRIC MATERALS

PDF Search Title:

VAPOR PHASE TREATMENT OF DELECTRIC MATERALSOriginal File Name Searched:

US7678712.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |