PDF Publication Title:

Text from PDF Page: 018

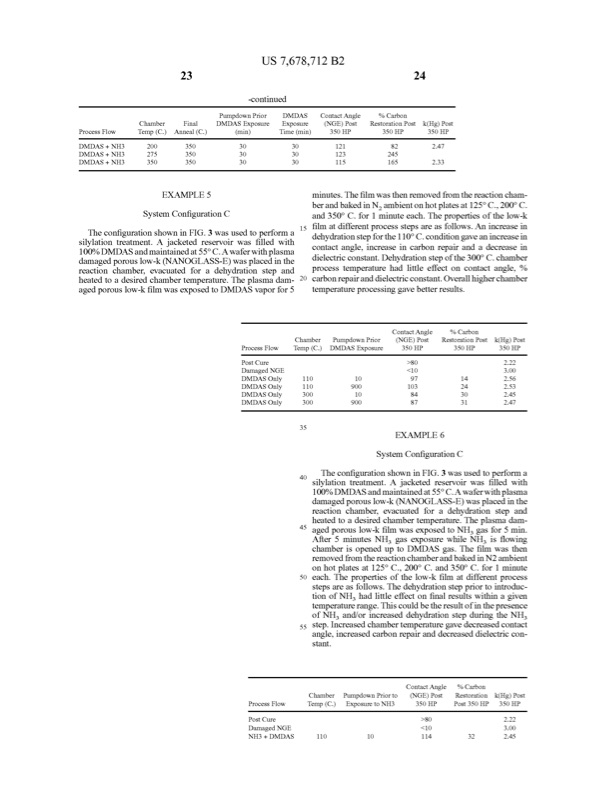

ProcessFlow DMDAS - NH3 DMDAS - NH3 DMDAS - NH3 Temp(C.) Anneal(C.) (min) Time(min) 2OO 275 350 350 30 30 350 30 30 350 30 30 350HP 350HP 350HP 121 82 2.47 123 245 115 16S 2.33 minutes.Thefilmwasthenremovedfromthereactioncham berandbakedinNambientonhotplatesat125°C.,200°C. EXAMPLE 5 SystemConfigurationC US 7,678,712B2 -continued PumpdownPrior DMDAS ContactAngle % Carbon Chamber Final DMDAS Exposure Exposure (NGE)Post RestorationPost k(Hg)Post and350°C.for1minuteeach.Thepropertiesofthelow-k 15 filmatdiferentprocessstepsareasfolows.Anincreasein TheconfigurationshowninFIG.3wasusedtoperforma dehydrationstepforthe110°C.conditiongaveanincreasein silylationtreatment.Ajacketedreservoirwasfiledwith contactangle.i b irandad 100%DMDASandmaintainedat55°C.Awaferwithplasma angle,increaseincarbonrepairan CaS 1 damagedporouslow-k(NANOGLASS-E)wasplacedinthe dielectricconstant.Dehydrationstepofthe300°C.chamber reactionchamber,evacuatedforadehydrationstepand processtemperaturehadlitleefectoncontactangle,9% heatedtoadesiredchambertemperature.Theplasmadam-20carbonrepairanddielectricconstant.Overalhigherchamber agedporouslow-kfilmwasexposedtoDMDASvaporfor5 temperatureprocessinggavebeterresults. ContactAngle % Carbon Chamber PumpdownPrior (NGE)Post RestorationPostk(Hg)Post ProcessFlow Temp(C.) DMDAS Exposure 350HP 350HP 350HP PostCure >80 2.22 DamagedNGE <10 3.00 DMDAS Only DMDAS Only DMDAS Only DMDAS Only 110 10 97 14 2.56 110 900 103 24 2.53 300 10 84 30 2.45 3OO 900 87 31 2.47 35 EXAMPLE 6 SystemConfigurationC TheconfigurationshowninFIG.3wasusedtoperforma silylationtreatment.A jacketedreservoirwas filedwith 100%DMDASandmaintainedat55°C.Awaferwithplasma damagedporouslow-k(NANOGLASS-E)wasplacedinthe reaction chamber, evacuated for a dehydration step and heatedtoadesiredchambertemperature.Theplasmadam agedporouslow-kfilmwasexposedtoNH gasfor5min. After5minutesNH gasexposurewhileNH isflowing chamberisopeneduptoDMDAS gas.Thefilmwasthen removedfromthereactionchamberandbakedinN2 ambient onhotplatesat125°C.,200°C.and350°C.for1minute 50 each.Thepropertiesofthelow-kfilmatdiferentprocess stepsareasfolows.Thedehydrationsteppriortointroduc tionofNH hadlitleefectonfinalresultswithinagiven temperaturerange.Thiscouldbetheresultofinthepresence ofNH and/orincreaseddehydrationstepduringtheNH s step.Increasedchambertemperaturegavedecreasedcontact angle,increasedcarbonrepairanddecreaseddielectriccon Stant. ContactAngle %Carbon Chamber PumpdownPriorto (NGE)Post Restoration k(Hg)Post ProcessFlow Temp(C.) ExposuretoNH3 350HP Post350HP 350HP PostCure DamagedNGE NH3 - DMDAS 110 10 >80 2.22 <10 3.00 114 32 2.45PDF Image | VAPOR PHASE TREATMENT OF DELECTRIC MATERALS

PDF Search Title:

VAPOR PHASE TREATMENT OF DELECTRIC MATERALSOriginal File Name Searched:

US7678712.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |