PDF Publication Title:

Text from PDF Page: 019

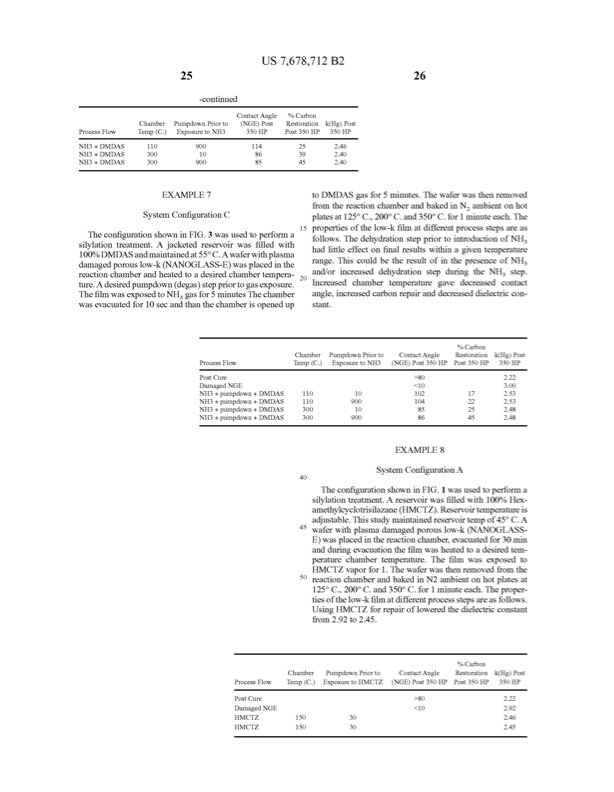

-continued ContactAngle %Carbon Chamber PumpdownPriorto (NGE)Post Restoration k(Hg)Post ProcessFlow Temp(C.) ExposuretoNH3 350HP Post350HP 350HP NH3 - DMDAS 110 900 114 25 NH3-DMDAS 3OO 10 86 39 NH3-DMDAS 3OO 900 85 45 EXAMPLE7 SystemConfigurationC TheconfigurationshowninFIG3wasusedtoperforma silylation treatment. A jacketed reservoir was filed with O 2.46 240 240 toDMDAS gasfor5minutes.Thewaferwasthenremoved fromthereactionchamberandbakedinN.ambientonhot platesat125°C.,200°C.and350°C.for1minuteeach.The 15 propertiesofthelow-kfilmatdiferentprocessstepsareas folows.ThedehydrationsteppriortointroductionofNH had li -0 adlitleefectonfinalresultswithinagiventemperature range.ThiscouldbetheresultofinthepresenceofNH 100%DMDASandmaintainedat55°C.Awaferwithplasma damagedporouslow-k(NANOGLASS-E)wasplacedinthe ProcessFlow PostCure DamagedNGE NH3 +pumpdown+DMDAS NH3 + pumpdown + DMDAS NH3 + pumpdown + DMDAS NH3 + pumpdown + DMDAS % Carbon ChamberPumpdownPriorto ContactAngle Restorationk(Hg)Post Temp(C.) ExposuretoNH3 (NGE)Post350HP Post350HP 350HP US 7,678,712B2 reactionchamberandheatedtoadesiredchambertempera- ture.Adesiredpumpdown(degas)steppriortogasexposure. Increasedchambertemperaturegavedecreasedcontact ThefilmwasexposedtoNHgasfor5minutesThechamber angle,increasedcarbonrepairanddecreaseddielectriccon wasevacuatedfor10secandthanthechamberisopenedup Stant. and/orincreaseddehydrationstepduringtheNH Step. >80 2.22 <10 3.00 102 17 2.53 104 22 2.53 85 25 2.48 86 45 2.48 EXAMPLE 8 SystemConfigurationA TheconfigurationshowninFIG.1wasusedtoperforma silylationtreatment.A reservoirwasfiledwith100%Hex amethylcyclotrisilazane(HMCTZ).Reservoirtemperatureis adjustable.Thisstudymaintainedreservoirtempof45°C.A waferwithplasmadamagedporouslow-k(NANOGLASS E)wasplacedinthereactionchamber,evacuatedfor30min andduringevacuationthefilmwasheatedtoadesiredtem perature chamber temperature. The film was exposed to HMCTZvaporfor1.Thewaferwasthenremovedfromthe reactionchamberandbakedinN2ambientonhotplatesat 125°C.,200°C.and350°C.for1minuteeach.Theproper tiesofthelow-kfilmatdiferentprocessstepsareasfolows. UsingHMCTZforrepairofloweredthedielectricconstant from2.92to2.45. 110 10 110 900 3OO 10 3OO 900 40 % Carbon Chamber PumpdownPriorto ContactAngle Restoration k(Hg)Post ProcessFlow Temp(C.) ExposuretoHMCTZ (NGE)Post350HP Post350HP 350HP PostCure >80 2.22 DamagedNGE <10 2.92 HMCTZ 150 30 2.46 HMCTZ 150 30 2.45PDF Image | VAPOR PHASE TREATMENT OF DELECTRIC MATERALS

PDF Search Title:

VAPOR PHASE TREATMENT OF DELECTRIC MATERALSOriginal File Name Searched:

US7678712.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |