PDF Publication Title:

Text from PDF Page: 022

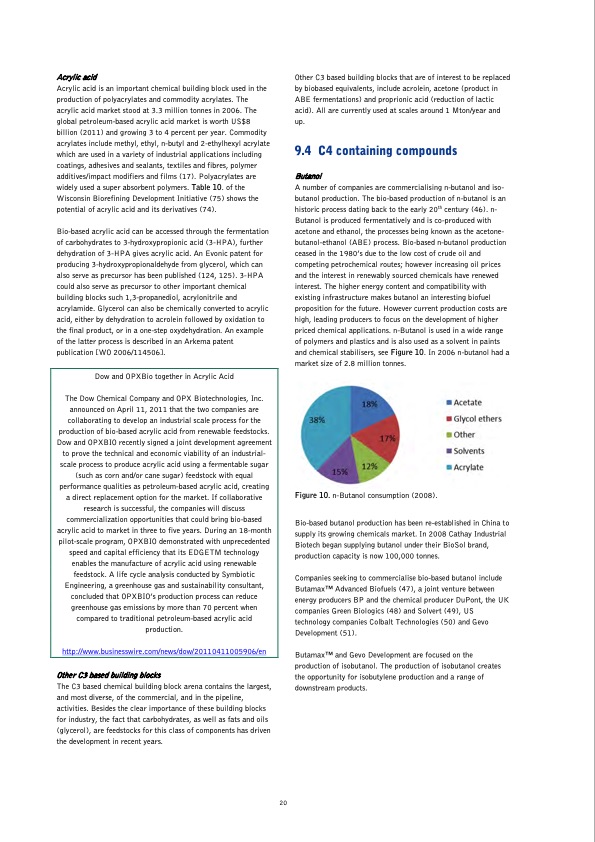

Acrylic acid Acrylic acid is an important chemical building block used in the production of polyacrylates and commodity acrylates. The acrylic acid market stood at 3.3 million tonnes in 2006. The global petroleum-based acrylic acid market is worth US$8 billion (2011) and growing 3 to 4 percent per year. Commodity acrylates include methyl, ethyl, n-butyl and 2-ethylhexyl acrylate which are used in a variety of industrial applications including coatings, adhesives and sealants, textiles and fibres, polymer additives/impact modifiers and films (17). Polyacrylates are widely used a super absorbent polymers. Table 10. of the Wisconsin Biorefining Development Initiative (75) shows the potential of acrylic acid and its derivatives (74). Bio-based acrylic acid can be accessed through the fermentation of carbohydrates to 3-hydroxypropionic acid (3-HPA), further dehydration of 3-HPA gives acrylic acid. An Evonic patent for producing 3-hydroxypropionaldehyde from glycerol, which can also serve as precursor has been published (124, 125). 3-HPA could also serve as precursor to other important chemical building blocks such 1,3-propanediol, acrylonitrile and acrylamide. Glycerol can also be chemically converted to acrylic acid, either by dehydration to acrolein followed by oxidation to the final product, or in a one-step oxydehydration. An example of the latter process is described in an Arkema patent publication [WO 2006/114506]. Dow and OPXBio together in Acrylic Acid The Dow Chemical Company and OPX Biotechnologies, Inc. announced on April 11, 2011 that the two companies are collaborating to develop an industrial scale process for the production of bio-based acrylic acid from renewable feedstocks. Dow and OPXBIO recently signed a joint development agreement to prove the technical and economic viability of an industrial- scale process to produce acrylic acid using a fermentable sugar (such as corn and/or cane sugar) feedstock with equal performance qualities as petroleum-based acrylic acid, creating a direct replacement option for the market. If collaborative research is successful, the companies will discuss commercialization opportunities that could bring bio-based acrylic acid to market in three to five years. During an 18-month pilot-scale program, OPXBIO demonstrated with unprecedented speed and capital efficiency that its EDGETM technology enables the manufacture of acrylic acid using renewable feedstock. A life cycle analysis conducted by Symbiotic Engineering, a greenhouse gas and sustainability consultant, concluded that OPXBIO’s production process can reduce greenhouse gas emissions by more than 70 percent when compared to traditional petroleum-based acrylic acid production. http://www.businesswire.com/news/dow/20110411005906/en Other C3 based building blocks The C3 based chemical building block arena contains the largest, and most diverse, of the commercial, and in the pipeline, activities. Besides the clear importance of these building blocks for industry, the fact that carbohydrates, as well as fats and oils (glycerol), are feedstocks for this class of components has driven the development in recent years. Other C3 based building blocks that are of interest to be replaced by biobased equivalents, include acrolein, acetone (product in ABE fermentations) and proprionic acid (reduction of lactic acid). All are currently used at scales around 1 Mton/year and up. 9.4 C4 containing compounds Butanol A number of companies are commercialising n-butanol and iso- butanol production. The bio-based production of n-butanol is an historic process dating back to the early 20th century (46). n- Butanol is produced fermentatively and is co-produced with acetone and ethanol, the processes being known as the acetone- butanol-ethanol (ABE) process. Bio-based n-butanol production ceased in the 1980’s due to the low cost of crude oil and competing petrochemical routes; however increasing oil prices and the interest in renewably sourced chemicals have renewed interest. The higher energy content and compatibility with existing infrastructure makes butanol an interesting biofuel proposition for the future. However current production costs are high, leading producers to focus on the development of higher priced chemical applications. n-Butanol is used in a wide range of polymers and plastics and is also used as a solvent in paints and chemical stabilisers, see Figure 10. In 2006 n-butanol had a market size of 2.8 million tonnes. Figure 10. n-Butanol consumption (2008). Bio-based butanol production has been re-established in China to supply its growing chemicals market. In 2008 Cathay Industrial Biotech began supplying butanol under their BioSol brand, production capacity is now 100,000 tonnes. Companies seeking to commercialise bio-based butanol include ButamaxTM Advanced Biofuels (47), a joint venture between energy producers BP and the chemical producer DuPont, the UK companies Green Biologics (48) and Solvert (49), US technology companies Colbalt Technologies (50) and Gevo Development (51). ButamaxTM and Gevo Development are focused on the production of isobutanol. The production of isobutanol creates the opportunity for isobutylene production and a range of downstream products. 20PDF Image | Bio-based Chemicals Value Added Products from Biorefineries

PDF Search Title:

Bio-based Chemicals Value Added Products from BiorefineriesOriginal File Name Searched:

Task-42-Biobased-Chemicals-value-added-products-from-biorefineries.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |