PDF Publication Title:

Text from PDF Page: 135

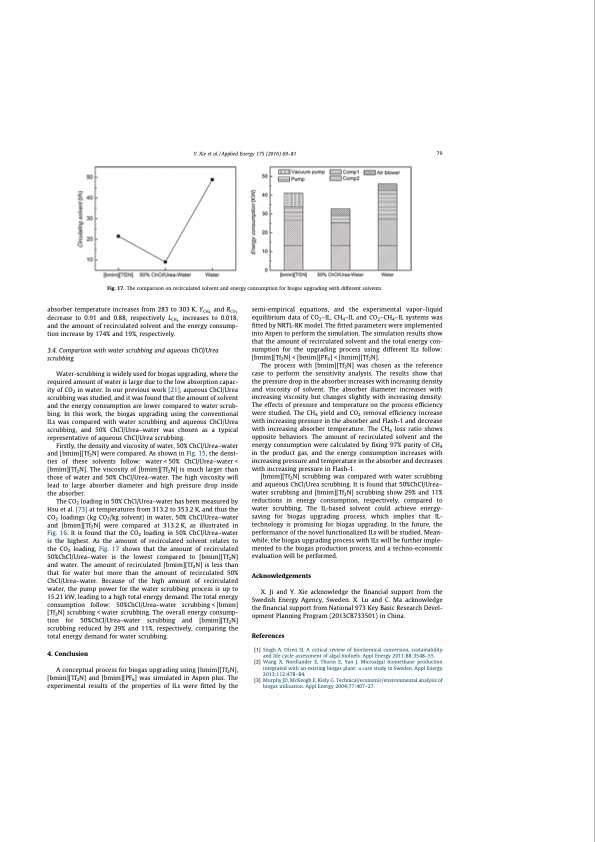

Y. Xie et al. / Applied Energy 175 (2016) 69–81 79 Fig. 17. The comparison on recirculated solvent and energy consumption for biogas upgrading with different solvents. absorber temperature increases from 283 to 303 K, YCH4 and RCO2 decrease to 0.91 and 0.88, respectively LCH4 increases to 0.018, and the amount of recirculated solvent and the energy consump- tion increase by 174% and 19%, respectively. 3.4. Comparison with water scrubbing and aqueous ChCl/Urea scrubbing Water-scrubbing is widely used for biogas upgrading, where the required amount of water is large due to the low absorption capac- ity of CO2 in water. In our previous work [21], aqueous ChCl/Urea scrubbing was studied, and it was found that the amount of solvent and the energy consumption are lower compared to water scrub- bing. In this work, the biogas upgrading using the conventional ILs was compared with water scrubbing and aqueous ChCl/Urea scrubbing, and 50% ChCl/Urea–water was chosen as a typical representative of aqueous ChCl/Urea scrubbing. Firstly, the density and viscosity of water, 50% ChCl/Urea–water and [bmim][Tf2N] were compared. As shown in Fig. 15, the densi- ties of these solvents follow: water < 50% ChCl/Urea–water < [bmim][Tf2N]. The viscosity of [bmim][Tf2N] is much larger than those of water and 50% ChCl/Urea–water. The high viscosity will lead to large absorber diameter and high pressure drop inside the absorber. The CO2 loading in 50% ChCl/Urea–water has been measured by Hsu et al. [73] at temperatures from 313.2 to 353.2 K, and thus the CO2 loadings (kg CO2/kg solvent) in water, 50% ChCl/Urea–water and [bmim][Tf2N] were compared at 313.2K, as illustrated in Fig. 16. It is found that the CO2 loading in 50% ChCl/Urea–water is the highest. As the amount of recirculated solvent relates to the CO2 loading, Fig. 17 shows that the amount of recirculated 50%ChCl/Urea–water is the lowest compared to [bmim][Tf2N] and water. The amount of recirculated [bmim][Tf2N] is less than that for water but more than the amount of recirculated 50% ChCl/Urea–water. Because of the high amount of recirculated water, the pump power for the water scrubbing process is up to 15.21 kW, leading to a high total energy demand. The total energy consumption follow: 50%ChCl/Urea–water scrubbing < [bmim] [Tf2N] scrubbing < water scrubbing. The overall energy consump- tion for 50%ChCl/Urea–water scrubbing and [bmim][Tf2N] scrubbing reduced by 29% and 11%, respectively, comparing the total energy demand for water scrubbing. 4. Conclusion A conceptual process for biogas upgrading using [hmim][Tf2N], [bmim][Tf2N] and [bmim][PF6] was simulated in Aspen plus. The experimental results of the properties of ILs were fitted by the semi-empirical equations, and the experimental vapor–liquid equilibrium data of CO2–IL, CH4–IL and CO2–CH4–IL systems was fitted by NRTL-RK model. The fitted parameters were implemented into Aspen to perform the simulation. The simulation results show that the amount of recirculated solvent and the total energy con- sumption for the upgrading process using different ILs follow: [bmim][Tf2N] < [bmim][PF6] < [hmim][Tf2N]. The process with [bmim][Tf2N] was chosen as the reference case to perform the sensitivity analysis. The results show that the pressure drop in the absorber increases with increasing density and viscosity of solvent. The absorber diameter increases with increasing viscosity but changes slightly with increasing density. The effects of pressure and temperature on the process efficiency were studied. The CH4 yield and CO2 removal efficiency increase with increasing pressure in the absorber and Flash-1 and decrease with increasing absorber temperature. The CH4 loss ratio shows opposite behaviors. The amount of recirculated solvent and the energy consumption were calculated by fixing 97% purity of CH4 in the product gas, and the energy consumption increases with increasing pressure and temperature in the absorber and decreases with increasing pressure in Flash-1. [bmim][Tf2N] scrubbing was compared with water scrubbing and aqueous ChCl/Urea scrubbing. It is found that 50%ChCl/Urea– water scrubbing and [bmim][Tf2N] scrubbing show 29% and 11% reductions in energy consumption, respectively, compared to water scrubbing. The IL-based solvent could achieve energy- saving for biogas upgrading process, which implies that IL- technology is promising for biogas upgrading. In the future, the performance of the novel functionalized ILs will be studied. Mean- while, the biogas upgrading process with ILs will be further imple- mented to the biogas production process, and a techno-economic evaluation will be performed. Acknowledgements X. Ji and Y. Xie acknowledge the financial support from the Swedish Energy Agency, Sweden. X. Lu and C. Ma acknowledge the financial support from National 973 Key Basic Research Devel- opment Planning Program (2013CB733501) in China. References [1] Singh A, Olsen SI. A critical review of biochemical conversion, sustainability and life cycle assessment of algal biofuels. Appl Energy 2011;88:3548–55. [2] Wang X, Nordlander E, Thorin E, Yan J. Microalgal biomethane production integrated with an existing biogas plant: a case study in Sweden. Appl Energy 2013;112:478–84. [3] Murphy JD, McKeogh E, Kiely G. Technical/economic/environmental analysis of biogas utilisation. Appl Energy 2004;77:407–27.PDF Image | CO2 Separation with Ionic Liquids

PDF Search Title:

CO2 Separation with Ionic LiquidsOriginal File Name Searched:

co2-separation-ionic-liquids.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |