PDF Publication Title:

Text from PDF Page: 006

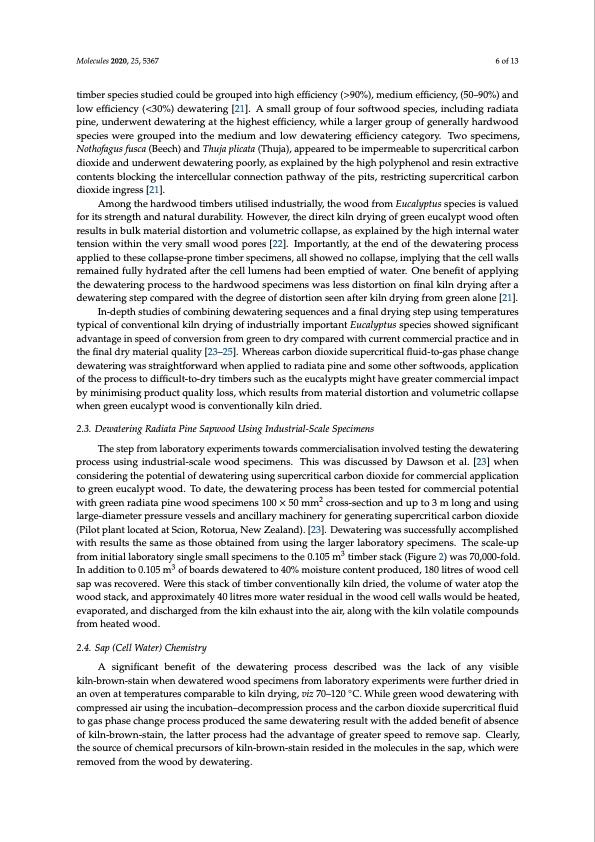

Molecules 2020, 25, 5367 6 of 13 timber species studied could be grouped into high efficiency (>90%), medium efficiency, (50–90%) and low efficiency (<30%) dewatering [21]. A small group of four softwood species, including radiata pine, underwent dewatering at the highest efficiency, while a larger group of generally hardwood species were grouped into the medium and low dewatering efficiency category. Two specimens, Nothofagus fusca (Beech) and Thuja plicata (Thuja), appeared to be impermeable to supercritical carbon dioxide and underwent dewatering poorly, as explained by the high polyphenol and resin extractive contents blocking the intercellular connection pathway of the pits, restricting supercritical carbon dioxide ingress [21]. Among the hardwood timbers utilised industrially, the wood from Eucalyptus species is valued for its strength and natural durability. However, the direct kiln drying of green eucalypt wood often results in bulk material distortion and volumetric collapse, as explained by the high internal water tension within the very small wood pores [22]. Importantly, at the end of the dewatering process applied to these collapse-prone timber specimens, all showed no collapse, implying that the cell walls remained fully hydrated after the cell lumens had been emptied of water. One benefit of applying the dewatering process to the hardwood specimens was less distortion on final kiln drying after a dewatering step compared with the degree of distortion seen after kiln drying from green alone [21]. In-depth studies of combining dewatering sequences and a final drying step using temperatures typical of conventional kiln drying of industrially important Eucalyptus species showed significant advantage in speed of conversion from green to dry compared with current commercial practice and in the final dry material quality [23–25]. Whereas carbon dioxide supercritical fluid-to-gas phase change dewatering was straightforward when applied to radiata pine and some other softwoods, application of the process to difficult-to-dry timbers such as the eucalypts might have greater commercial impact by minimising product quality loss, which results from material distortion and volumetric collapse when green eucalypt wood is conventionally kiln dried. 2.3. Dewatering Radiata Pine Sapwood Using Industrial-Scale Specimens The step from laboratory experiments towards commercialisation involved testing the dewatering process using industrial-scale wood specimens. This was discussed by Dawson et al. [23] when considering the potential of dewatering using supercritical carbon dioxide for commercial application to green eucalypt wood. To date, the dewatering process has been tested for commercial potential with green radiata pine wood specimens 100 × 50 mm2 cross-section and up to 3 m long and using large-diameter pressure vessels and ancillary machinery for generating supercritical carbon dioxide (Pilot plant located at Scion, Rotorua, New Zealand). [23]. Dewatering was successfully accomplished with results the same as those obtained from using the larger laboratory specimens. The scale-up from initial laboratory single small specimens to the 0.105 m3 timber stack (Figure 2) was 70,000-fold. In addition to 0.105 m3 of boards dewatered to 40% moisture content produced, 180 litres of wood cell sap was recovered. Were this stack of timber conventionally kiln dried, the volume of water atop the wood stack, and approximately 40 litres more water residual in the wood cell walls would be heated, evaporated, and discharged from the kiln exhaust into the air, along with the kiln volatile compounds from heated wood. 2.4. Sap (Cell Water) Chemistry A significant benefit of the dewatering process described was the lack of any visible kiln-brown-stain when dewatered wood specimens from laboratory experiments were further dried in an oven at temperatures comparable to kiln drying, viz 70–120 ◦C. While green wood dewatering with compressed air using the incubation–decompression process and the carbon dioxide supercritical fluid to gas phase change process produced the same dewatering result with the added benefit of absence of kiln-brown-stain, the latter process had the advantage of greater speed to remove sap. Clearly, the source of chemical precursors of kiln-brown-stain resided in the molecules in the sap, which were removed from the wood by dewatering.PDF Image | Dewatering Green Sapwood Using Carbon Dioxide

PDF Search Title:

Dewatering Green Sapwood Using Carbon DioxideOriginal File Name Searched:

molecules-25-05367.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |