PDF Publication Title:

Text from PDF Page: 009

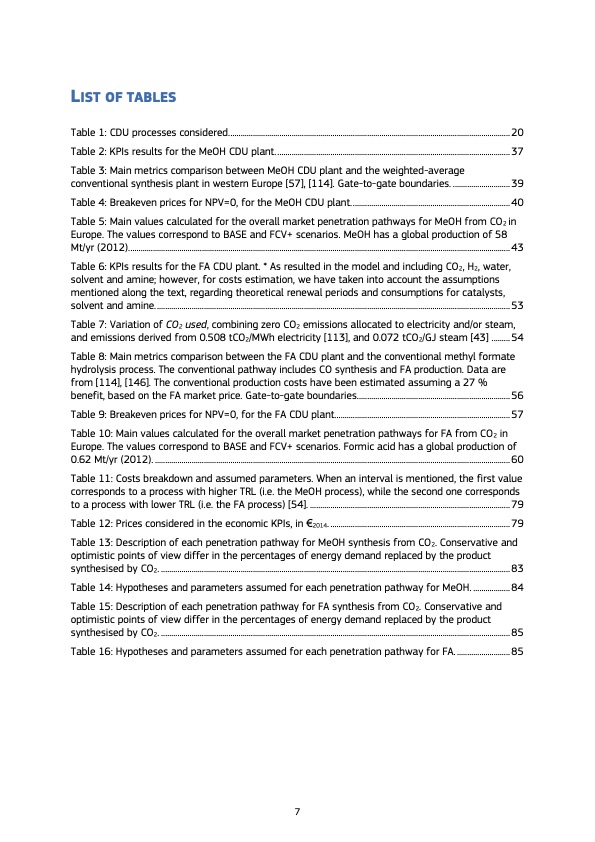

LIST OF TABLES Table 1: CDU processes considered..........................................................................................................................................20 Table 2: KPIs results for the MeOH CDU plant...................................................................................................................37 Table 3: Main metrics comparison between MeOH CDU plant and the weighted-average conventional synthesis plant in western Europe [57], [114]. Gate-to-gate boundaries. ............................ 39 Table 4: Breakeven prices for NPV=0, for the MeOH CDU plant..............................................................................40 Table 5: Main values calculated for the overall market penetration pathways for MeOH from CO2 in Europe. The values correspond to BASE and FCV+ scenarios. MeOH has a global production of 58 Mt/yr (2012)........................................................................................................................................................................................... 43 Table 6: KPIs results for the FA CDU plant. * As resulted in the model and including CO2, H2, water, solvent and amine; however, for costs estimation, we have taken into account the assumptions mentioned along the text, regarding theoretical renewal periods and consumptions for catalysts, solvent and amine..............................................................................................................................................................................53 Table 7: Variation of CO2 used, combining zero CO2 emissions allocated to electricity and/or steam, and emissions derived from 0.508 tCO2/MWh electricity [113], and 0.072 tCO2/GJ steam [43] ......... 54 Table 8: Main metrics comparison between the FA CDU plant and the conventional methyl formate hydrolysis process. The conventional pathway includes CO synthesis and FA production. Data are from [114], [146]. The conventional production costs have been estimated assuming a 27 % benefit, based on the FA market price. Gate-to-gate boundaries........................................................................... 56 Table 9: Breakeven prices for NPV=0, for the FA CDU plant......................................................................................57 Table 10: Main values calculated for the overall market penetration pathways for FA from CO2 in Europe. The values correspond to BASE and FCV+ scenarios. Formic acid has a global production of 0.62 Mt/yr (2012). .............................................................................................................................................................................. 60 Table 11: Costs breakdown and assumed parameters. When an interval is mentioned, the first value corresponds to a process with higher TRL (i.e. the MeOH process), while the second one corresponds to a process with lower TRL (i.e. the FA process) [54]. .................................................................................................. 79 Table 12: Prices considered in the economic KPIs, in €2014. ........................................................................................ 79 Table 13: Description of each penetration pathway for MeOH synthesis from CO2. Conservative and optimistic points of view differ in the percentages of energy demand replaced by the product synthesised by CO2. ........................................................................................................................................................................... 83 Table 14: Hypotheses and parameters assumed for each penetration pathway for MeOH. .................. 84 Table 15: Description of each penetration pathway for FA synthesis from CO2. Conservative and optimistic points of view differ in the percentages of energy demand replaced by the product synthesised by CO2. ........................................................................................................................................................................... 85 Table 16: Hypotheses and parameters assumed for each penetration pathway for FA. .......................... 85 7PDF Image | evaluation of CO2 utilisation for fuel production

PDF Search Title:

evaluation of CO2 utilisation for fuel productionOriginal File Name Searched:

ld1a27629enn.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |