PDF Publication Title:

Text from PDF Page: 036

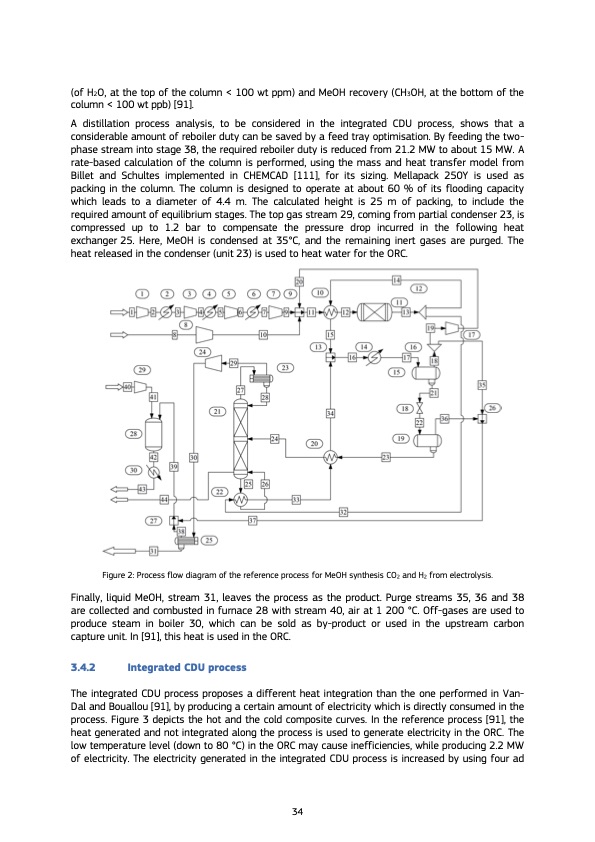

(of H2O, at the top of the column < 100 wt ppm) and MeOH recovery (CH3OH, at the bottom of the column < 100 wt ppb) [91]. A distillation process analysis, to be considered in the integrated CDU process, shows that a considerable amount of reboiler duty can be saved by a feed tray optimisation. By feeding the two- phase stream into stage 38, the required reboiler duty is reduced from 21.2 MW to about 15 MW. A rate-based calculation of the column is performed, using the mass and heat transfer model from Billet and Schultes implemented in CHEMCAD [111], for its sizing. Mellapack 250Y is used as packing in the column. The column is designed to operate at about 60 % of its flooding capacity which leads to a diameter of 4.4 m. The calculated height is 25 m of packing, to include the required amount of equilibrium stages. The top gas stream 29, coming from partial condenser 23, is compressed up to 1.2 bar to compensate the pressure drop incurred in the following heat exchanger 25. Here, MeOH is condensed at 35°C, and the remaining inert gases are purged. The heat released in the condenser (unit 23) is used to heat water for the ORC. Figure 2: Process flow diagram of the reference process for MeOH synthesis CO2 and H2 from electrolysis. Finally, liquid MeOH, stream 31, leaves the process as the product. Purge streams 35, 36 and 38 are collected and combusted in furnace 28 with stream 40, air at 1 200 °C. Off-gases are used to produce steam in boiler 30, which can be sold as by-product or used in the upstream carbon capture unit. In [91], this heat is used in the ORC. 3.4.2 Integrated CDU process The integrated CDU process proposes a different heat integration than the one performed in Van- Dal and Bouallou [91], by producing a certain amount of electricity which is directly consumed in the process. Figure 3 depicts the hot and the cold composite curves. In the reference process [91], the heat generated and not integrated along the process is used to generate electricity in the ORC. The low temperature level (down to 80 °C) in the ORC may cause inefficiencies, while producing 2.2 MW of electricity. The electricity generated in the integrated CDU process is increased by using four ad 34PDF Image | evaluation of CO2 utilisation for fuel production

PDF Search Title:

evaluation of CO2 utilisation for fuel productionOriginal File Name Searched:

ld1a27629enn.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |