PDF Publication Title:

Text from PDF Page: 052

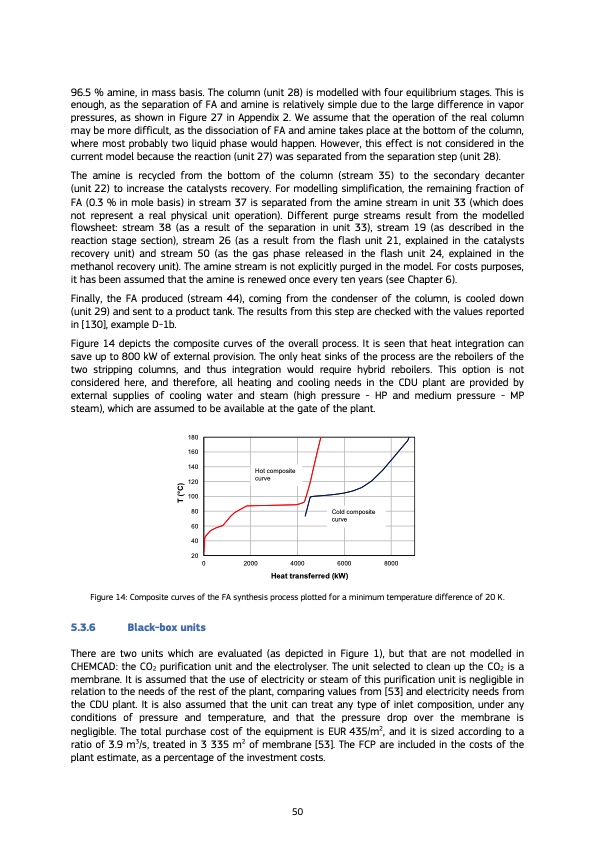

96.5 % amine, in mass basis. The column (unit 28) is modelled with four equilibrium stages. This is enough, as the separation of FA and amine is relatively simple due to the large difference in vapor pressures, as shown in Figure 27 in Appendix 2. We assume that the operation of the real column may be more difficult, as the dissociation of FA and amine takes place at the bottom of the column, where most probably two liquid phase would happen. However, this effect is not considered in the current model because the reaction (unit 27) was separated from the separation step (unit 28). The amine is recycled from the bottom of the column (stream 35) to the secondary decanter (unit 22) to increase the catalysts recovery. For modelling simplification, the remaining fraction of FA (0.3 % in mole basis) in stream 37 is separated from the amine stream in unit 33 (which does not represent a real physical unit operation). Different purge streams result from the modelled flowsheet: stream 38 (as a result of the separation in unit 33), stream 19 (as described in the reaction stage section), stream 26 (as a result from the flash unit 21, explained in the catalysts recovery unit) and stream 50 (as the gas phase released in the flash unit 24, explained in the methanol recovery unit). The amine stream is not explicitly purged in the model. For costs purposes, it has been assumed that the amine is renewed once every ten years (see Chapter 6). Finally, the FA produced (stream 44), coming from the condenser of the column, is cooled down (unit 29) and sent to a product tank. The results from this step are checked with the values reported in [130], example D-1b. Figure 14 depicts the composite curves of the overall process. It is seen that heat integration can save up to 800 kW of external provision. The only heat sinks of the process are the reboilers of the two stripping columns, and thus integration would require hybrid reboilers. This option is not considered here, and therefore, all heating and cooling needs in the CDU plant are provided by external supplies of cooling water and steam (high pressure - HP and medium pressure - MP steam), which are assumed to be available at the gate of the plant. 180 160 140 120 100 80 60 40 20 Hot composite curve Cold composite curve 0 2000 4000 6000 8000 Heat transferred (kW) Figure 14: Composite curves of the FA synthesis process plotted for a minimum temperature difference of 20 K. 5.3.6 Black-box units There are two units which are evaluated (as depicted in Figure 1), but that are not modelled in CHEMCAD: the CO2 purification unit and the electrolyser. The unit selected to clean up the CO2 is a membrane. It is assumed that the use of electricity or steam of this purification unit is negligible in relation to the needs of the rest of the plant, comparing values from [53] and electricity needs from the CDU plant. It is also assumed that the unit can treat any type of inlet composition, under any conditions of pressure and temperature, and that the pressure drop over the membrane is negligible. The total purchase cost of the equipment is EUR 435/m2, and it is sized according to a ratio of 3.9 m3/s, treated in 3 335 m2 of membrane [53]. The FCP are included in the costs of the plant estimate, as a percentage of the investment costs. 50 T ( C)PDF Image | evaluation of CO2 utilisation for fuel production

PDF Search Title:

evaluation of CO2 utilisation for fuel productionOriginal File Name Searched:

ld1a27629enn.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |