PDF Publication Title:

Text from PDF Page: 056

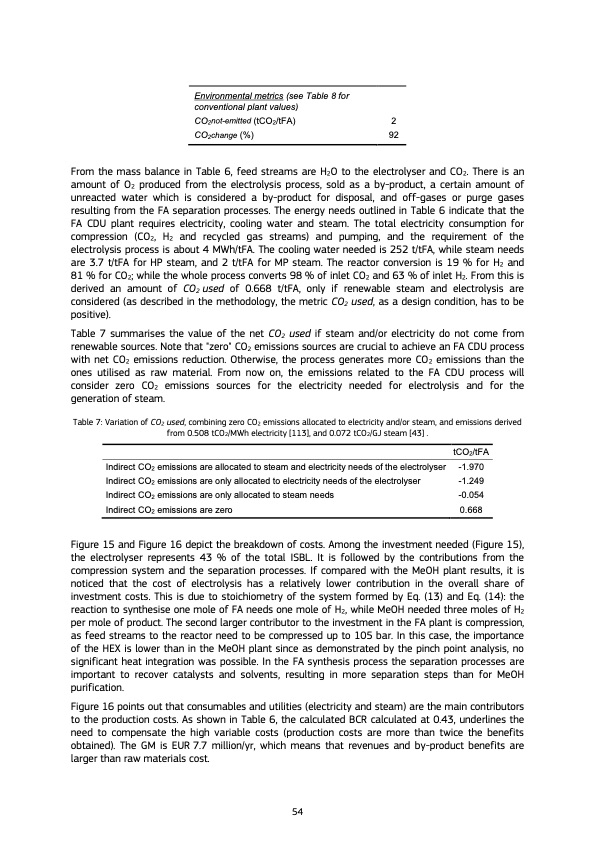

Environmental metrics (see Table 8 for conventional plant values) CO2not-emitted (tCO2/tFA) 2 CO2change (%) 92 From the mass balance in Table 6, feed streams are H2O to the electrolyser and CO2. There is an amount of O2 produced from the electrolysis process, sold as a by-product, a certain amount of unreacted water which is considered a by-product for disposal, and off-gases or purge gases resulting from the FA separation processes. The energy needs outlined in Table 6 indicate that the FA CDU plant requires electricity, cooling water and steam. The total electricity consumption for compression (CO2, H2 and recycled gas streams) and pumping, and the requirement of the electrolysis process is about 4 MWh/tFA. The cooling water needed is 252 t/tFA, while steam needs are 3.7 t/tFA for HP steam, and 2 t/tFA for MP steam. The reactor conversion is 19 % for H2 and 81 % for CO2; while the whole process converts 98 % of inlet CO2 and 63 % of inlet H2. From this is derived an amount of CO2 used of 0.668 t/tFA, only if renewable steam and electrolysis are considered (as described in the methodology, the metric CO2 used, as a design condition, has to be positive). Table 7 summarises the value of the net CO2 used if steam and/or electricity do not come from renewable sources. Note that "zero" CO2 emissions sources are crucial to achieve an FA CDU process with net CO2 emissions reduction. Otherwise, the process generates more CO2 emissions than the ones utilised as raw material. From now on, the emissions related to the FA CDU process will consider zero CO2 emissions sources for the electricity needed for electrolysis and for the generation of steam. Table 7: Variation of CO2 used, combining zero CO2 emissions allocated to electricity and/or steam, and emissions derived from 0.508 tCO2/MWh electricity [113], and 0.072 tCO2/GJ steam [43] . Indirect CO2 emissions are allocated to steam and electricity needs of the electrolyser Indirect CO2 emissions are only allocated to electricity needs of the electrolyser Indirect CO2 emissions are only allocated to steam needs Indirect CO2 emissions are zero tCO2/tFA -1.970 -1.249 -0.054 0.668 Figure 15 and Figure 16 depict the breakdown of costs. Among the investment needed (Figure 15), the electrolyser represents 43 % of the total ISBL. It is followed by the contributions from the compression system and the separation processes. If compared with the MeOH plant results, it is noticed that the cost of electrolysis has a relatively lower contribution in the overall share of investment costs. This is due to stoichiometry of the system formed by Eq. (13) and Eq. (14): the reaction to synthesise one mole of FA needs one mole of H2, while MeOH needed three moles of H2 per mole of product. The second larger contributor to the investment in the FA plant is compression, as feed streams to the reactor need to be compressed up to 105 bar. In this case, the importance of the HEX is lower than in the MeOH plant since as demonstrated by the pinch point analysis, no significant heat integration was possible. In the FA synthesis process the separation processes are important to recover catalysts and solvents, resulting in more separation steps than for MeOH purification. Figure 16 points out that consumables and utilities (electricity and steam) are the main contributors to the production costs. As shown in Table 6, the calculated BCR calculated at 0.43, underlines the need to compensate the high variable costs (production costs are more than twice the benefits obtained). The GM is EUR 7.7 million/yr, which means that revenues and by-product benefits are larger than raw materials cost. 54PDF Image | evaluation of CO2 utilisation for fuel production

PDF Search Title:

evaluation of CO2 utilisation for fuel productionOriginal File Name Searched:

ld1a27629enn.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |