PDF Publication Title:

Text from PDF Page: 002

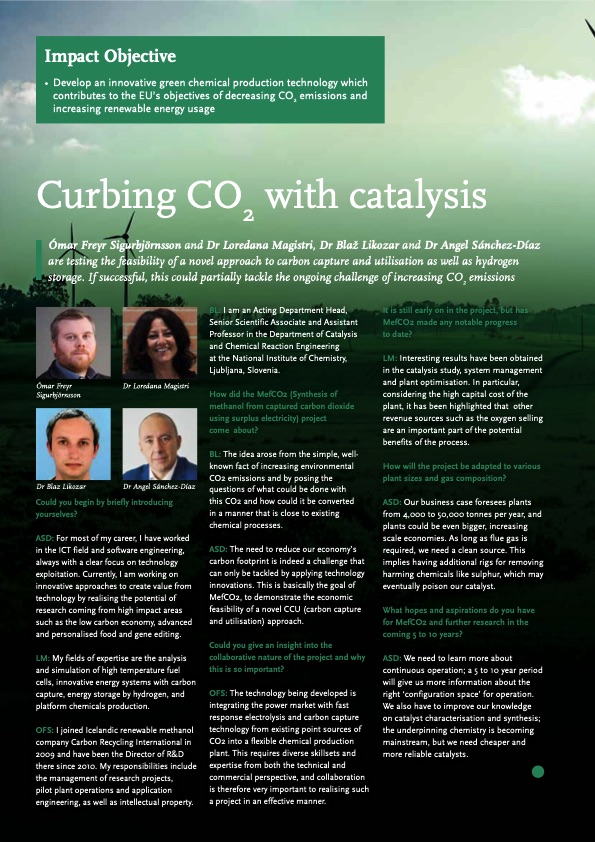

Impact Objective • Develop an innovative green chemical production technology which contributes to the EU’s objectives of decreasing CO2 emissions and increasing renewable energy usage Curbing CO2 with catalysis Ómar Freyr Sigurbjörnsson and Dr Loredana Magistri, Dr Blaž Likozar and Dr Angel Sánchez-Díaz are testing the feasibility of a novel approach to carbon capture and utilisation as well as hydrogen storage. If successful, this could partially tackle the ongoing challenge of increasing CO2 emissions Ómar Freyr Sigurbjörnsson Dr Blaz Likozar Dr Loredana Magistri Dr Angel Sánchez-Díaz BL: I am an Acting Department Head, Senior Scientific Associate and Assistant Professor in the Department of Catalysis and Chemical Reaction Engineering at the National Institute of Chemistry, Ljubljana, Slovenia. How did the MefCO2 (Synthesis of methanol from captured carbon dioxide using surplus electricity) project come about? BL: The idea arose from the simple, well- known fact of increasing environmental CO2 emissions and by posing the questions of what could be done with this CO2 and how could it be converted in a manner that is close to existing chemical processes. ASD: The need to reduce our economy’s carbon footprint is indeed a challenge that can only be tackled by applying technology innovations. This is basically the goal of MefCO2, to demonstrate the economic feasibility of a novel CCU (carbon capture and utilisation) approach. Could you give an insight into the collaborative nature of the project and why this is so important? OFS: The technology being developed is integrating the power market with fast response electrolysis and carbon capture technology from existing point sources of CO2 into a flexible chemical production plant. This requires diverse skillsets and expertise from both the technical and commercial perspective, and collaboration is therefore very important to realising such a project in an effective manner. It is still early on in the project, but has MefCO2 made any notable progress to date? LM: Interesting results have been obtained in the catalysis study, system management and plant optimisation. In particular, considering the high capital cost of the plant, it has been highlighted that other revenue sources such as the oxygen selling are an important part of the potential benefits of the process. How will the project be adapted to various plant sizes and gas composition? ASD: Our business case foresees plants from 4,000 to 50,000 tonnes per year, and plants could be even bigger, increasing scale economies. As long as flue gas is required, we need a clean source. This implies having additional rigs for removing harming chemicals like sulphur, which may eventually poison our catalyst. What hopes and aspirations do you have for MefCO2 and further research in the coming 5 to 10 years? ASD: We need to learn more about continuous operation; a 5 to 10 year period will give us more information about the right ‘configuration space’ for operation. We also have to improve our knowledge on catalyst characterisation and synthesis; the underpinning chemistry is becoming mainstream, but we need cheaper and more reliable catalysts. Could you begin by briefly introducing yourselves? ASD: For most of my career, I have worked in the ICT field and software engineering, always with a clear focus on technology exploitation. Currently, I am working on innovative approaches to create value from technology by realising the potential of research coming from high impact areas such as the low carbon economy, advanced and personalised food and gene editing. LM: My fields of expertise are the analysis and simulation of high temperature fuel cells, innovative energy systems with carbon capture, energy storage by hydrogen, and platform chemicals production. OFS: I joined Icelandic renewable methanol company Carbon Recycling International in 2009 and have been the Director of R&D there since 2010. My responsibilities include the management of research projects, pilot plant operations and application engineering, as well as intellectual property.PDF Image | GREEN METHANOL FOR A GREEN FUTURE

PDF Search Title:

GREEN METHANOL FOR A GREEN FUTUREOriginal File Name Searched:

MefCO2_Brochure_00.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |