PDF Publication Title:

Text from PDF Page: 003

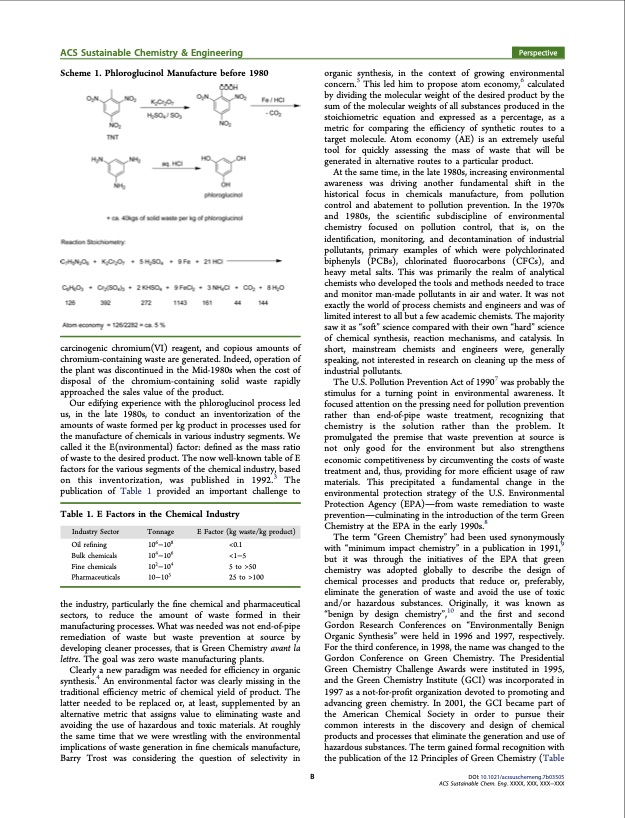

ACS Sustainable Chemistry & Engineering Perspective Scheme 1. Phloroglucinol Manufacture before 1980 carcinogenic chromium(VI) reagent, and copious amounts of chromium-containing waste are generated. Indeed, operation of the plant was discontinued in the Mid-1980s when the cost of disposal of the chromium-containing solid waste rapidly approached the sales value of the product. Our edifying experience with the phloroglucinol process led us, in the late 1980s, to conduct an inventorization of the amounts of waste formed per kg product in processes used for the manufacture of chemicals in various industry segments. We called it the E(nvironmental) factor: defined as the mass ratio of waste to the desired product. The now well-known table of E factors for the various segments of the chemical industry, based on this inventorization, was published in 1992.3 The publication of Table 1 provided an important challenge to Table 1. E Factors in the Chemical Industry organic synthesis, in the context of growing environmental concern.5 This led him to propose atom economy,6 calculated by dividing the molecular weight of the desired product by the sum of the molecular weights of all substances produced in the stoichiometric equation and expressed as a percentage, as a metric for comparing the efficiency of synthetic routes to a target molecule. Atom economy (AE) is an extremely useful tool for quickly assessing the mass of waste that will be generated in alternative routes to a particular product. At the same time, in the late 1980s, increasing environmental awareness was driving another fundamental shift in the historical focus in chemicals manufacture, from pollution control and abatement to pollution prevention. In the 1970s and 1980s, the scientific subdiscipline of environmental chemistry focused on pollution control, that is, on the identification, monitoring, and decontamination of industrial pollutants, primary examples of which were polychlorinated biphenyls (PCBs), chlorinated fluorocarbons (CFCs), and heavy metal salts. This was primarily the realm of analytical chemists who developed the tools and methods needed to trace and monitor man-made pollutants in air and water. It was not exactly the world of process chemists and engineers and was of limited interest to all but a few academic chemists. The majority saw it as “soft” science compared with their own “hard” science of chemical synthesis, reaction mechanisms, and catalysis. In short, mainstream chemists and engineers were, generally speaking, not interested in research on cleaning up the mess of industrial pollutants. The U.S. Pollution Prevention Act of 19907 was probably the stimulus for a turning point in environmental awareness. It focused attention on the pressing need for pollution prevention rather than end-of-pipe waste treatment, recognizing that chemistry is the solution rather than the problem. It promulgated the premise that waste prevention at source is not only good for the environment but also strengthens economic competitiveness by circumventing the costs of waste treatment and, thus, providing for more efficient usage of raw materials. This precipitated a fundamental change in the environmental protection strategy of the U.S. Environmental Protection Agency (EPA)from waste remediation to waste preventionculminating in the introduction of the term Green Chemistry at the EPA in the early 1990s.8 The term “Green Chemistry” had been used synonymously with “minimum impact chemistry” in a publication in 1991,9 but it was through the initiatives of the EPA that green chemistry was adopted globally to describe the design of chemical processes and products that reduce or, preferably, eliminate the generation of waste and avoid the use of toxic and/or hazardous substances. Originally, it was known as “benign by design chemistry”,10 and the first and second Gordon Research Conferences on “Environmentally Benign Organic Synthesis” were held in 1996 and 1997, respectively. For the third conference, in 1998, the name was changed to the Gordon Conference on Green Chemistry. The Presidential Green Chemistry Challenge Awards were instituted in 1995, and the Green Chemistry Institute (GCI) was incorporated in 1997 as a not-for-profit organization devoted to promoting and advancing green chemistry. In 2001, the GCI became part of the American Chemical Society in order to pursue their common interests in the discovery and design of chemical products and processes that eliminate the generation and use of hazardous substances. The term gained formal recognition with the publication of the 12 Principles of Green Chemistry (Table DOI: 10.1021/acssuschemeng.7b03505 ACS Sustainable Chem. Eng. XXXX, XXX, XXX−XXX Industry Sector Oil refining Bulk chemicals Fine chemicals Pharmaceuticals Tonnage 68 10 −10 104−106 102−104 10−103 E Factor (kg waste/kg product) <0.1 <1−5 5 to >50 25 to >100 the industry, particularly the fine chemical and pharmaceutical sectors, to reduce the amount of waste formed in their manufacturing processes. What was needed was not end-of-pipe remediation of waste but waste prevention at source by developing cleaner processes, that is Green Chemistry avant la lettre. The goal was zero waste manufacturing plants. Clearly a new paradigm was needed for efficiency in organic synthesis.4 An environmental factor was clearly missing in the traditional efficiency metric of chemical yield of product. The latter needed to be replaced or, at least, supplemented by an alternative metric that assigns value to eliminating waste and avoiding the use of hazardous and toxic materials. At roughly the same time that we were wrestling with the environmental implications of waste generation in fine chemicals manufacture, Barry Trost was considering the question of selectivity in BPDF Image | Metrics of Green Chemistry and Sustainability

PDF Search Title:

Metrics of Green Chemistry and SustainabilityOriginal File Name Searched:

acssuschemeng.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |