PDF Publication Title:

Text from PDF Page: 007

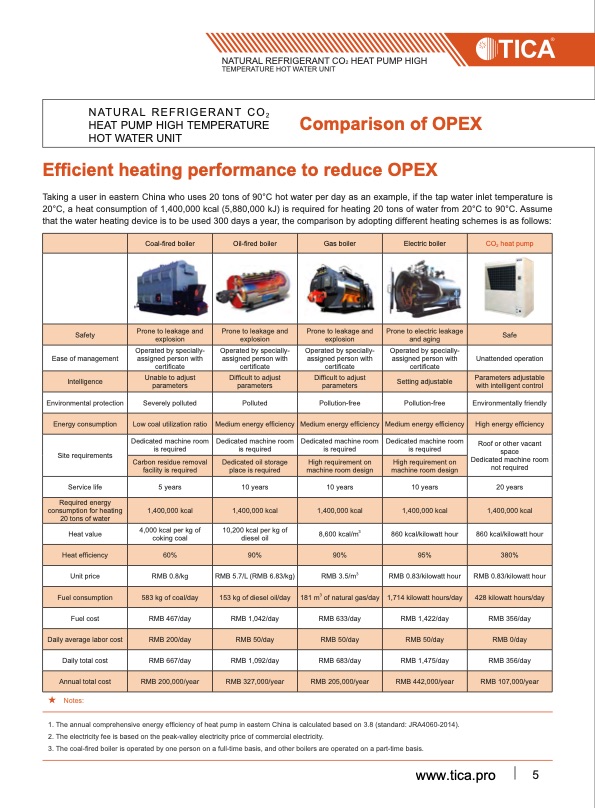

NATURAL REFRIGERANT CO2 HEAT PUMP HIGH TEMPERATURE HOT WATER UNIT Efficient heating performance to reduce OPEX Taking a user in eastern China who uses 20 tons of 90°C hot water per day as an example, if the tap water inlet temperature is 20°C, a heat consumption of 1,400,000 kcal (5,880,000 kJ) is required for heating 20 tons of water from 20°C to 90°C. Assume that the water heating device is to be used 300 days a year, the comparison by adopting different heating schemes is as follows: Coal-fired boiler Oil-fired boiler Gas boiler Electric boiler CO2 heat pump Safety Prone to leakage and explosion Prone to leakage and explosion Prone to leakage and explosion Prone to electric leakage and aging Safe Ease of management Environmental protection Site requirements Service life Heat value Unit price Fuel cost Daily total cost Notes: Operated by specially- assigned person with certificate Severely polluted Dedicated machine room is required 5 years 4,000 kcal per kg of coking coal RMB 0.8/kg RMB 467/day RMB 667/day Operated by specially- assigned person with certificate Polluted Dedicated machine room is required 10 years 10,200 kcal per kg of diesel oil RMB 5.7/L (RMB 6.83/kg) RMB 1,042/day RMB 1,092/day Operated by specially- assigned person with certificate Pollution-free Dedicated machine room is required 10 years 8,600 kcal/m3 RMB 3.5/m3 RMB 633/day RMB 683/day Operated by specially- assigned person with certificate Pollution-free Dedicated machine room is required 10 years 860 kcal/kilowatt hour RMB 0.83/kilowatt hour RMB 1,422/day RMB 1,475/day Unattended operation Environmentally friendly Roof or other vacant space Dedicated machine room not required 20 years 860 kcal/kilowatt hour RMB 0.83/kilowatt hour RMB 356/day RMB 356/day Intelligence Unable to adjust parameters Difficult to adjust parameters Difficult to adjust parameters Setting adjustable Parameters adjustable with intelligent control Energy consumption Low coal utilization ratio Medium energy efficiency Medium energy efficiency Medium energy efficiency High energy efficiency Carbon residue removal facility is required Dedicated oil storage place is required High requirement on machine room design High requirement on machine room design Required energy consumption for heating 20 tons of water 1,400,000 kcal 1,400,000 kcal 1,400,000 kcal 1,400,000 kcal 1,400,000 kcal Heat efficiency 60% 90% 90% 95% 380% Fuel consumption 583 kg of coal/day 153 kg of diesel oil/day 181 m3 of natural gas/day 1,714 kilowatt hours/day 428 kilowatt hours/day Daily average labor cost RMB 200/day RMB 50/day RMB 50/day RMB 50/day RMB 0/day Annual total cost RMB 200,000/year RMB 327,000/year RMB 205,000/year RMB 442,000/year RMB 107,000/year 1. The annual comprehensive energy efficiency of heat pump in eastern China is calculated based on 3.8 (standard: JRA4060-2014). 2. The electricity fee is based on the peak-valley electricity price of commercial electricity. 3. The coal-fired boiler is operated by one person on a full-time basis, and other boilers are operated on a part-time basis. www.tica.pro 5 NATURAL REFRIGERANT CO2 HEAT PUMP HIGH TEMPERATURE HOT WATER UNIT Comparison of OPEXPDF Image | CO2 HEAT PUMP High Temp Hot Water

PDF Search Title:

CO2 HEAT PUMP High Temp Hot WaterOriginal File Name Searched:

heat-pump-co2-english.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |