PDF Publication Title:

Text from PDF Page: 020

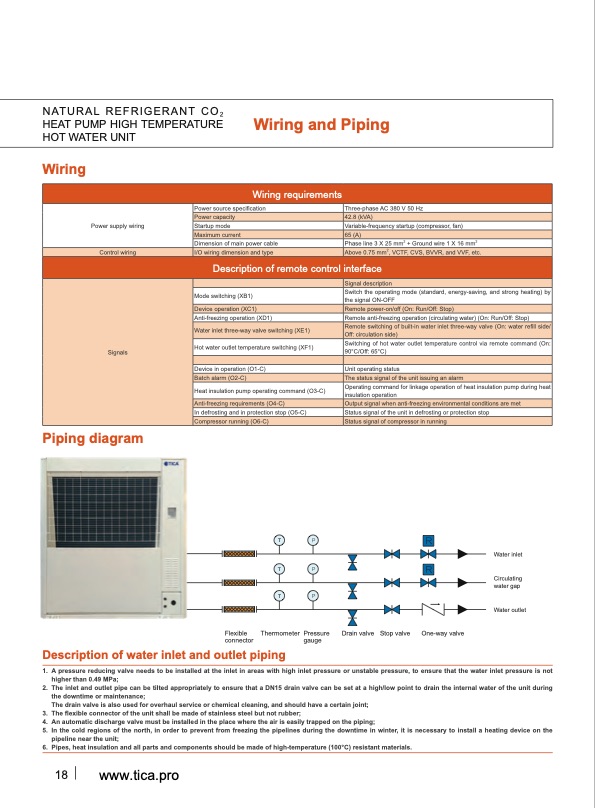

NATURAL REFRIGERANT CO2 HEAT PUMP HIGH TEMPERATURE HOT WATER UNIT Wiring and Piping Wiring requirements Power capacity 42.8 (kVA) Maximum current 65 (A) Control wiring I/O wiring dimension and type Above 0.75 mm2, VCTF, CVS, BVVR, and VVF, etc. Description of remote control interface Signal description Device operation (XC1) Remote power-on/off (On: Run/Off: Stop) Water inlet three-way valve switching (XE1) Remote switching of built-in water inlet three-way valve (On: water refill side/ Off: circulation side) Signals Batch alarm (O2-C) The status signal of the unit issuing an alarm Anti-freezing requirements (O4-C) Output signal when anti-freezing environmental conditions are met Compressor running (O6-C) Status signal of compressor in running Wiring Power supply wiring Power source specification Startup mode Dimension of main power cable Mode switching (XB1) Anti-freezing operation (XD1) Hot water outlet temperature switching (XF1) Device in operation (O1-C) Heat insulation pump operating command (O3-C) In defrosting and in protection stop (O5-C) Three-phase AC 380 V 50 Hz Variable-frequency startup (compressor, fan) Phase line 3 X 25 mm2 + Ground wire 1 X 16 mm2 Switch the operating mode (standard, energy-saving, and strong heating) by the signal ON-OFF Remote anti-freezing operation (circulating water) (On: Run/Off: Stop) Switching of hot water outlet temperature control via remote command (On: 90°C/Off: 65°C) Unit operating status Operating command for linkage operation of heat insulation pump during heat insulation operation Status signal of the unit in defrosting or protection stop Piping diagram T T T Thermometer Pressure gauge Water inlet Circulating water gap Water outlet Description of water inlet and outlet piping Flexible connector Drain valve Stop valve One-way valve 1. A pressure reducing valve needs to be installed at the inlet in areas with high inlet pressure or unstable pressure, to ensure that the water inlet pressure is not higher than 0.49 MPa; 2. The inlet and outlet pipe can be tilted appropriately to ensure that a DN15 drain valve can be set at a high/low point to drain the internal water of the unit during the downtime or maintenance; The drain valve is also used for overhaul service or chemical cleaning, and should have a certain joint; 3. The flexible connector of the unit shall be made of stainless steel but not rubber; 4. An automatic discharge valve must be installed in the place where the air is easily trapped on the piping; 5. In the cold regions of the north, in order to prevent from freezing the pipelines during the downtime in winter, it is necessary to install a heating device on the pipeline near the unit; 6. Pipes, heat insulation and all parts and components should be made of high-temperature (100°C) resistant materials. 18 www.tica.proPDF Image | CO2 HEAT PUMP High Temp Hot Water

PDF Search Title:

CO2 HEAT PUMP High Temp Hot WaterOriginal File Name Searched:

heat-pump-co2-english.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |