PDF Publication Title:

Text from PDF Page: 014

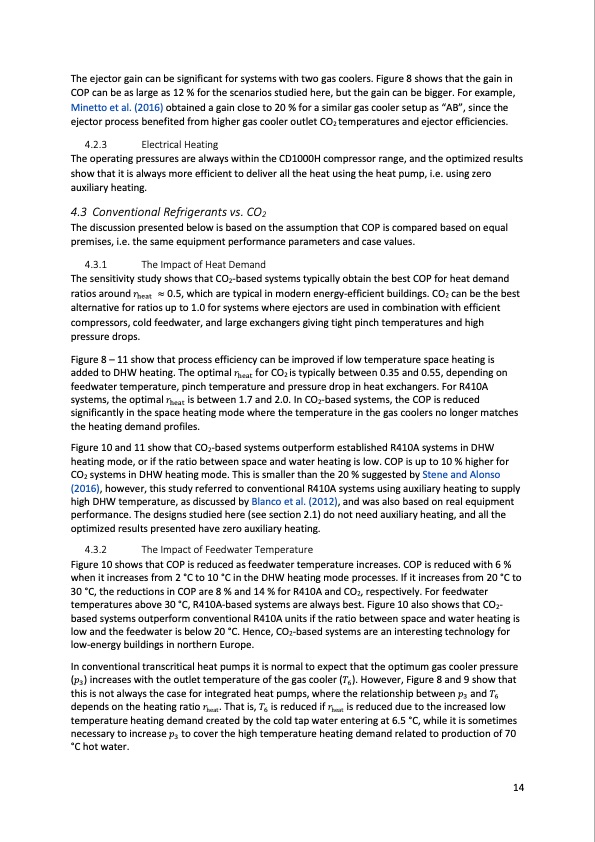

The ejector gain can be significant for systems with two gas coolers. Figure 8 shows that the gain in COP can be as large as 12 % for the scenarios studied here, but the gain can be bigger. For example, Minetto et al. (2016) obtained a gain close to 20 % for a similar gas cooler setup as “AB”, since the ejector process benefited from higher gas cooler outlet CO2 temperatures and ejector efficiencies. 4.2.3 Electrical Heating The operating pressures are always within the CD1000H compressor range, and the optimized results show that it is always more efficient to deliver all the heat using the heat pump, i.e. using zero auxiliary heating. 4.3 Conventional Refrigerants vs. CO2 The discussion presented below is based on the assumption that COP is compared based on equal premises, i.e. the same equipment performance parameters and case values. 4.3.1 The Impact of Heat Demand The sensitivity study shows that CO2-based systems typically obtain the best COP for heat demand ratios around 𝑟𝑟 ≈ 0.5, which are typical in modern energy-efficient buildings. CO2 can be the best alternative for ratios up to 1.0 for systems where ejectors are used in combination with efficient compressors, cold feedwater, and large exchangers giving tight pinch temperatures and high pressure drops. heat Figure 8 – 11 show that process efficiency can be improved if low temperature space heating is added to DHW heating. The optimal 𝑟𝑟 for CO2 is typically between 0.35 and 0.55, depending on heat feedwater temperature, pinch temperature and pressure drop in heat exchangers. For R410A systems, the optimal 𝑟𝑟 is between 1.7 and 2.0. In CO2-based systems, the COP is reduced heat significantly in the space heating mode where the temperature in the gas coolers no longer matches the heating demand profiles. Figure 10 and 11 show that CO2-based systems outperform established R410A systems in DHW heating mode, or if the ratio between space and water heating is low. COP is up to 10 % higher for CO2 systems in DHW heating mode. This is smaller than the 20 % suggested by Stene and Alonso (2016), however, this study referred to conventional R410A systems using auxiliary heating to supply high DHW temperature, as discussed by Blanco et al. (2012), and was also based on real equipment performance. The designs studied here (see section 2.1) do not need auxiliary heating, and all the optimized results presented have zero auxiliary heating. 4.3.2 The Impact of Feedwater Temperature Figure 10 shows that COP is reduced as feedwater temperature increases. COP is reduced with 6 % when it increases from 2 °C to 10 °C in the DHW heating mode processes. If it increases from 20 °C to 30 °C, the reductions in COP are 8 % and 14 % for R410A and CO2, respectively. For feedwater temperatures above 30 °C, R410A-based systems are always best. Figure 10 also shows that CO2- based systems outperform conventional R410A units if the ratio between space and water heating is low and the feedwater is below 20 °C. Hence, CO2-based systems are an interesting technology for low-energy buildings in northern Europe. In conventional transcritical heat pumps it is normal to expect that the optimum gas cooler pressure (𝑝𝑝 ) increases with the outlet temperature of the gas cooler (𝑇𝑇 ). However, Figure 8 and 9 show that 36 this is not always the case for integrated heat pumps, where the relationship between 𝑝𝑝3 and 𝑇𝑇6 depends on the heating ratio 𝑟𝑟heat. That is, 𝑇𝑇6 is reduced if 𝑟𝑟heat is reduced due to the increased low necessary to increase 𝑝𝑝 to cover the high temperature heating demand related to production of 70 temperature heating demand created by the cold tap water entering at 6.5 °C, while it is sometimes °C hot water. 3 14PDF Image | CO2 Heat Pump Performance

PDF Search Title:

CO2 Heat Pump PerformanceOriginal File Name Searched:

co2-heat-pump-comparative-study.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |