PDF Publication Title:

Text from PDF Page: 080

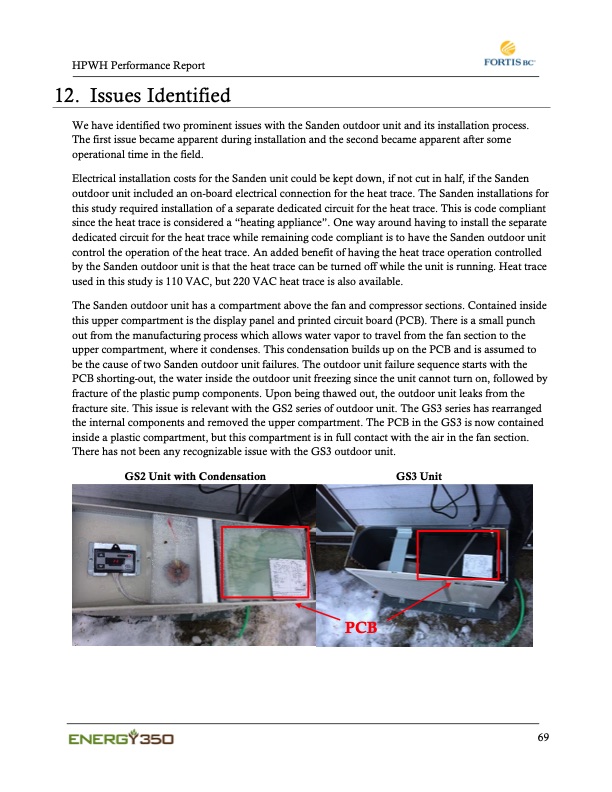

HPWH Performance Report 12. Issues Identified We have identified two prominent issues with the Sanden outdoor unit and its installation process. The first issue became apparent during installation and the second became apparent after some operational time in the field. Electrical installation costs for the Sanden unit could be kept down, if not cut in half, if the Sanden outdoor unit included an on-board electrical connection for the heat trace. The Sanden installations for this study required installation of a separate dedicated circuit for the heat trace. This is code compliant since the heat trace is considered a “heating appliance”. One way around having to install the separate dedicated circuit for the heat trace while remaining code compliant is to have the Sanden outdoor unit control the operation of the heat trace. An added benefit of having the heat trace operation controlled by the Sanden outdoor unit is that the heat trace can be turned off while the unit is running. Heat trace used in this study is 110 VAC, but 220 VAC heat trace is also available. The Sanden outdoor unit has a compartment above the fan and compressor sections. Contained inside this upper compartment is the display panel and printed circuit board (PCB). There is a small punch out from the manufacturing process which allows water vapor to travel from the fan section to the upper compartment, where it condenses. This condensation builds up on the PCB and is assumed to be the cause of two Sanden outdoor unit failures. The outdoor unit failure sequence starts with the PCB shorting-out, the water inside the outdoor unit freezing since the unit cannot turn on, followed by fracture of the plastic pump components. Upon being thawed out, the outdoor unit leaks from the fracture site. This issue is relevant with the GS2 series of outdoor unit. The GS3 series has rearranged the internal components and removed the upper compartment. The PCB in the GS3 is now contained inside a plastic compartment, but this compartment is in full contact with the air in the fan section. There has not been any recognizable issue with the GS3 outdoor unit. GS2 Unit with Condensation GS3 Unit PCB 69PDF Image | CO2 Integrated Heat Pump Water Heater

PDF Search Title:

CO2 Integrated Heat Pump Water HeaterOriginal File Name Searched:

CO2-Integrated-Heat-Pump-perf.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |