PDF Publication Title:

Text from PDF Page: 012

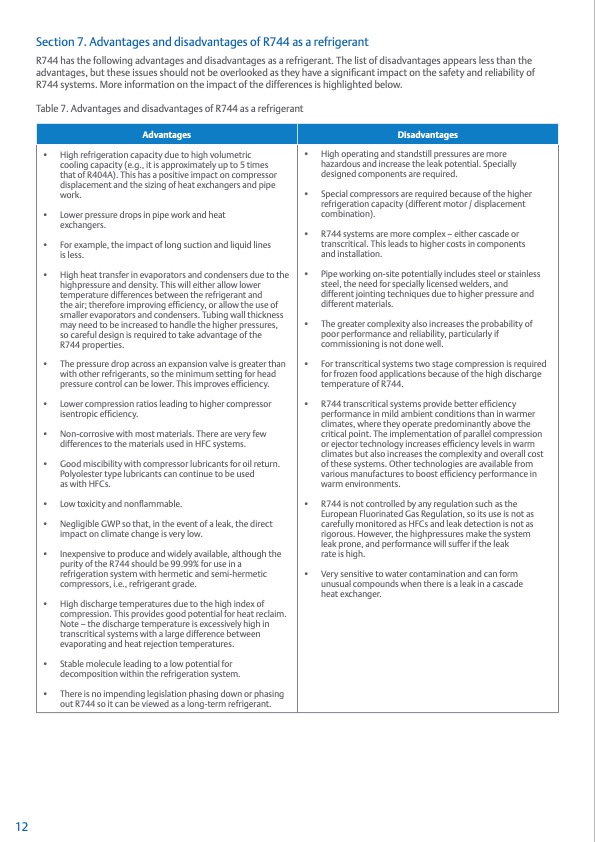

Section 7. Advantages and disadvantages of R744 as a refrigerant R744 has the following advantages and disadvantages as a refrigerant. The list of disadvantages appears less than the advantages, but these issues should not be overlooked as they have a significant impact on the safety and reliability of R744 systems. More information on the impact of the differences is highlighted below. Table 7. Advantages and disadvantages of R744 as a refrigerant Advantages Disadvantages • High refrigeration capacity due to high volumetric cooling capacity (e.g., it is approximately up to 5 times that of R404A). This has a positive impact on compressor displacement and the sizing of heat exchangers and pipe work. • Lower pressure drops in pipe work and heat exchangers. • For example, the impact of long suction and liquid lines is less. • High heat transfer in evaporators and condensers due to the highpressure and density. This will either allow lower temperature differences between the refrigerant and the air; therefore improving efficiency, or allow the use of smaller evaporators and condensers. Tubing wall thickness may need to be increased to handle the higher pressures, so careful design is required to take advantage of the R744 properties. • The pressure drop across an expansion valve is greater than with other refrigerants, so the minimum setting for head pressure control can be lower. This improves efficiency. • Lower compression ratios leading to higher compressor isentropic efficiency. • Non-corrosive with most materials. There are very few differences to the materials used in HFC systems. • Good miscibility with compressor lubricants for oil return. Polyolester type lubricants can continue to be used as with HFCs. • Low toxicity and nonflammable. • Negligible GWP so that, in the event of a leak, the direct impact on climate change is very low. • Inexpensive to produce and widely available, although the purity of the R744 should be 99.99% for use in a refrigeration system with hermetic and semi-hermetic compressors, i.e., refrigerant grade. • High discharge temperatures due to the high index of compression. This provides good potential for heat reclaim. Note – the discharge temperature is excessively high in transcritical systems with a large difference between evaporating and heat rejection temperatures. • Stable molecule leading to a low potential for decomposition within the refrigeration system. • There is no impending legislation phasing down or phasing out R744 so it can be viewed as a long-term refrigerant. • High operating and standstill pressures are more hazardous and increase the leak potential. Specially designed components are required. • Special compressors are required because of the higher refrigeration capacity (different motor / displacement combination). • R744 systems are more complex – either cascade or transcritical. This leads to higher costs in components and installation. • Pipe working on-site potentially includes steel or stainless steel, the need for specially licensed welders, and different jointing techniques due to higher pressure and different materials. • The greater complexity also increases the probability of poor performance and reliability, particularly if commissioning is not done well. • For transcritical systems two stage compression is required for frozen food applications because of the high discharge temperature of R744. • R744 transcritical systems provide better efficiency performance in mild ambient conditions than in warmer climates, where they operate predominantly above the critical point. The implementation of parallel compression or ejector technology increases efficiency levels in warm climates but also increases the complexity and overall cost of these systems. Other technologies are available from various manufactures to boost efficiency performance in warm environments. • R744 is not controlled by any regulation such as the European Fluorinated Gas Regulation, so its use is not as carefully monitored as HFCs and leak detection is not as rigorous. However, the highpressures make the system leak prone, and performance will suffer if the leak rate is high. • Very sensitive to water contamination and can form unusual compounds when there is a leak in a cascade heat exchanger. 12PDF Image | CO2 Product Guide 2021

PDF Search Title:

CO2 Product Guide 2021Original File Name Searched:

2021-co2-refrigeration-4217772.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |