PDF Publication Title:

Text from PDF Page: 028

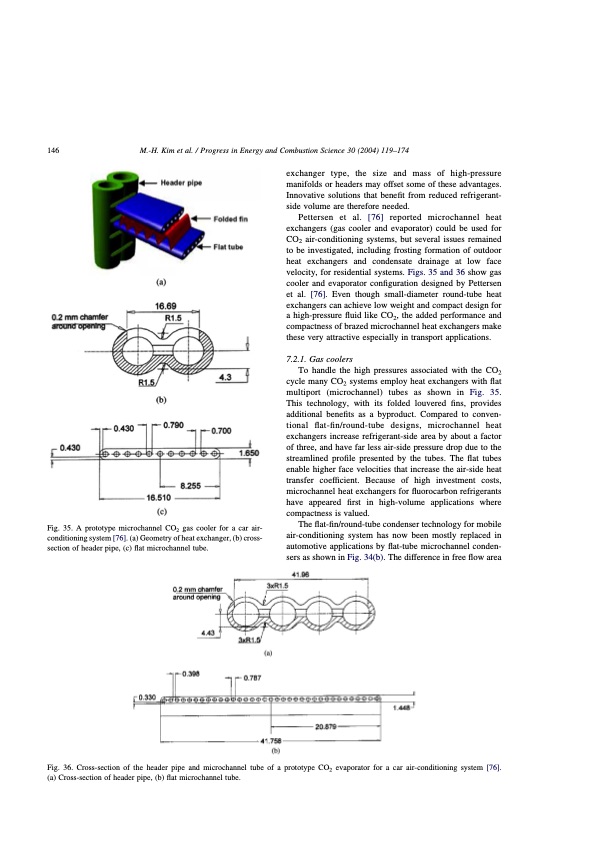

146 M.-H. Kim et al. / Progress in Energy and Combustion Science 30 (2004) 119–174 Fig. 35. A prototype microchannel CO2 gas cooler for a car air- conditioning system [76]. (a) Geometry of heat exchanger, (b) cross- section of header pipe, (c) flat microchannel tube. exchanger type, the size and mass of high-pressure manifolds or headers may offset some of these advantages. Innovative solutions that benefit from reduced refrigerant- side volume are therefore needed. Pettersen et al. [76] reported microchannel heat exchangers (gas cooler and evaporator) could be used for CO2 air-conditioning systems, but several issues remained to be investigated, including frosting formation of outdoor heat exchangers and condensate drainage at low face velocity, for residential systems. Figs. 35 and 36 show gas cooler and evaporator configuration designed by Pettersen et al. [76]. Even though small-diameter round-tube heat exchangers can achieve low weight and compact design for a high-pressure fluid like CO2, the added performance and compactness of brazed microchannel heat exchangers make these very attractive especially in transport applications. 7.2.1. Gas coolers To handle the high pressures associated with the CO2 cycle many CO2 systems employ heat exchangers with flat multiport (microchannel) tubes as shown in Fig. 35. This technology, with its folded louvered fins, provides additional benefits as a byproduct. Compared to conven- tional flat-fin/round-tube designs, microchannel heat exchangers increase refrigerant-side area by about a factor of three, and have far less air-side pressure drop due to the streamlined profile presented by the tubes. The flat tubes enable higher face velocities that increase the air-side heat transfer coefficient. Because of high investment costs, microchannel heat exchangers for fluorocarbon refrigerants have appeared first in high-volume applications where compactness is valued. The flat-fin/round-tube condenser technology for mobile air-conditioning system has now been mostly replaced in automotive applications by flat-tube microchannel conden- sers as shown in Fig. 34(b). The difference in free flow area Fig. 36. Cross-section of the header pipe and microchannel tube of a prototype CO2 evaporator for a car air-conditioning system [76]. (a) Cross-section of header pipe, (b) flat microchannel tube.PDF Image | CO2 Vapor Compression Systems

PDF Search Title:

CO2 Vapor Compression SystemsOriginal File Name Searched:

co2-vapor-compression-systems.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |