PDF Publication Title:

Text from PDF Page: 008

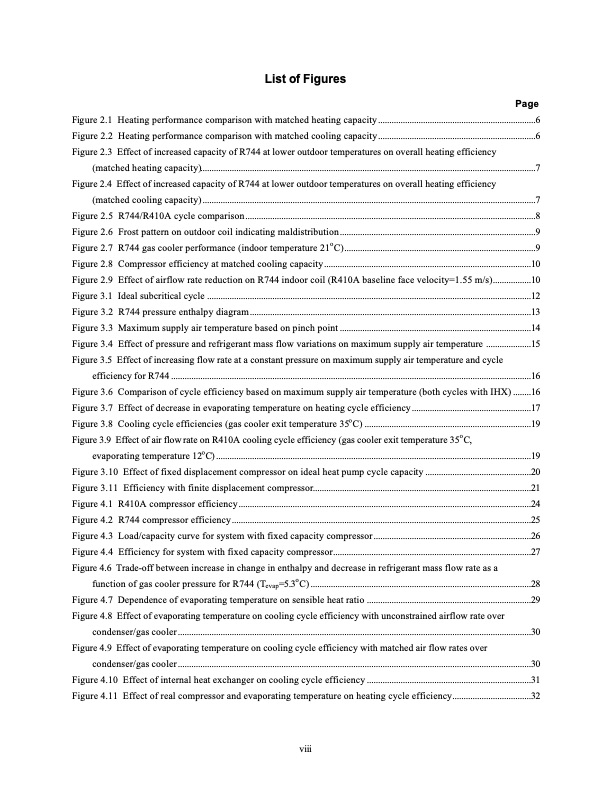

List of Figures Figure 2.1 Heating performance comparison with matched heating capacity......................................................................6 Figure 2.2 Heating performance comparison with matched cooling capacity......................................................................6 Figure 2.3 Effect of increased capacity of R744 at lower outdoor temperatures on overall heating efficiency (matched heating capacity).....................................................................................................................................................7 Figure 2.4 Effect of increased capacity of R744 at lower outdoor temperatures on overall heating efficiency (matched cooling capacity)....................................................................................................................................................7 Figure 2.5 R744/R410A cycle comparison.................................................................................................................................8 Figure 2.6 Frost pattern on outdoor coil indicating maldistribution.......................................................................................9 Figure 2.7 R744 gas cooler performance (indoor temperature 21oC).....................................................................................9 Figure 2.8 Compressor efficiency at matched cooling capacity............................................................................................10 Figure 2.9 Effect of airflow rate reduction on R744 indoor coil (R410A baseline face velocity=1.55 m/s).................10 Figure 3.1 Ideal subcritical cycle ................................................................................................................................................12 Figure 3.2 R744 pressure enthalpy diagram.............................................................................................................................13 Figure 3.3 Maximum supply air temperature based on pinch point .....................................................................................14 Figure 3.4 Effect of pressure and refrigerant mass flow variations on maximum supply air temperature ....................15 Figure 3.5 Effect of increasing flow rate at a constant pressure on maximum supply air temperature and cycle efficiency for R744 ................................................................................................................................................................16 Figure 3.6 Comparison of cycle efficiency based on maximum supply air temperature (both cycles with IHX) ........16 Figure 3.7 Effect of decrease in evaporating temperature on heating cycle efficiency.....................................................17 Figure 3.8 Cooling cycle efficiencies (gas cooler exit temperature 35oC) ..........................................................................19 Figure 3.9 Effect of air flow rate on R410A cooling cycle efficiency (gas cooler exit temperature 35oC, evaporating temperature 12oC) ............................................................................................................................................19 Figure 3.10 Effect of fixed displacement compressor on ideal heat pump cycle capacity ...............................................20 Figure 3.11 Efficiency with finite displacement compressor.................................................................................................21 Figure 4.1 R410A compressor efficiency..................................................................................................................................24 Figure 4.2 R744 compressor efficiency.....................................................................................................................................25 Figure 4.3 Load/capacity curve for system with fixed capacity compressor......................................................................26 Figure 4.4 Efficiency for system with fixed capacity compressor........................................................................................27 Figure 4.6 Trade-off between increase in change in enthalpy and decrease in refrigerant mass flow rate as a function of gas cooler pressure for R744 (Tevap=5.3oC)..................................................................................................28 Figure 4.7 Dependence of evaporating temperature on sensible heat ratio .........................................................................29 Figure 4.8 Effect of evaporating temperature on cooling cycle efficiency with unconstrained airflow rate over condenser/gas cooler.............................................................................................................................................................30 Figure 4.9 Effect of evaporating temperature on cooling cycle efficiency with matched air flow rates over condenser/gas cooler.............................................................................................................................................................30 Figure 4.10 Effect of internal heat exchanger on cooling cycle efficiency .........................................................................31 Figure 4.11 Effect of real compressor and evaporating temperature on heating cycle efficiency...................................32 viii PagePDF Image | Comparison of R744 and R410A

PDF Search Title:

Comparison of R744 and R410AOriginal File Name Searched:

CR039.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |