PDF Publication Title:

Text from PDF Page: 026

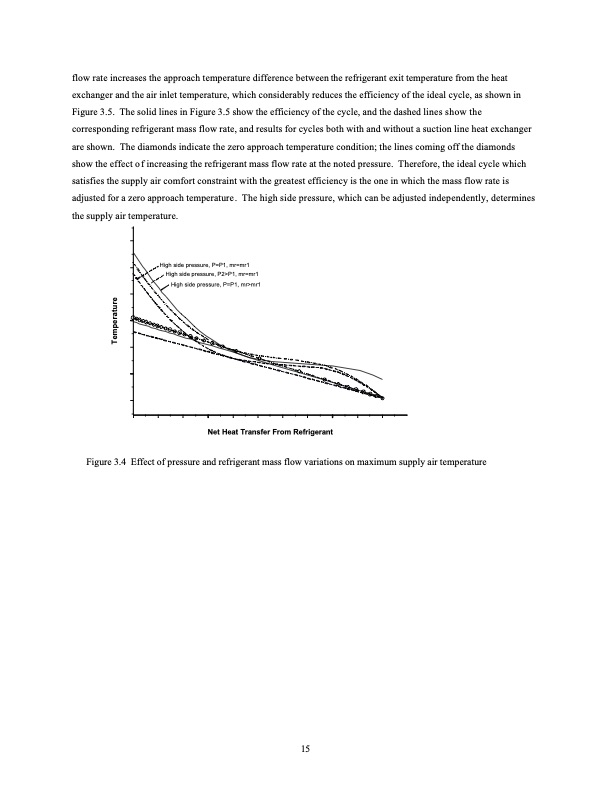

flow rate increases the approach temperature difference between the refrigerant exit temperature from the heat exchanger and the air inlet temperature, which considerably reduces the efficiency of the ideal cycle, as shown in Figure 3.5. The solid lines in Figure 3.5 show the efficiency of the cycle, and the dashed lines show the corresponding refrigerant mass flow rate, and results for cycles both with and without a suction line heat exchanger are shown. The diamonds indicate the zero approach temperature condition; the lines coming off the diamonds show the effect of increasing the refrigerant mass flow rate at the noted pressure. Therefore, the ideal cycle which satisfies the supply air comfort constraint with the greatest efficiency is the one in which the mass flow rate is adjusted for a zero approach temperature. The high side pressure, which can be adjusted independently, determines the supply air temperature. High side pressure, P=P1, mr=mr1 High side pressure, P2>P1, mr=mr1 High side pressure, P=P1, mr>mr1 Net Heat Transfer From Refrigerant Figure 3.4 Effect of pressure and refrigerant mass flow variations on maximum supply air temperature 15 TemperaturePDF Image | Comparison of R744 and R410A

PDF Search Title:

Comparison of R744 and R410AOriginal File Name Searched:

CR039.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |