PDF Publication Title:

Text from PDF Page: 002

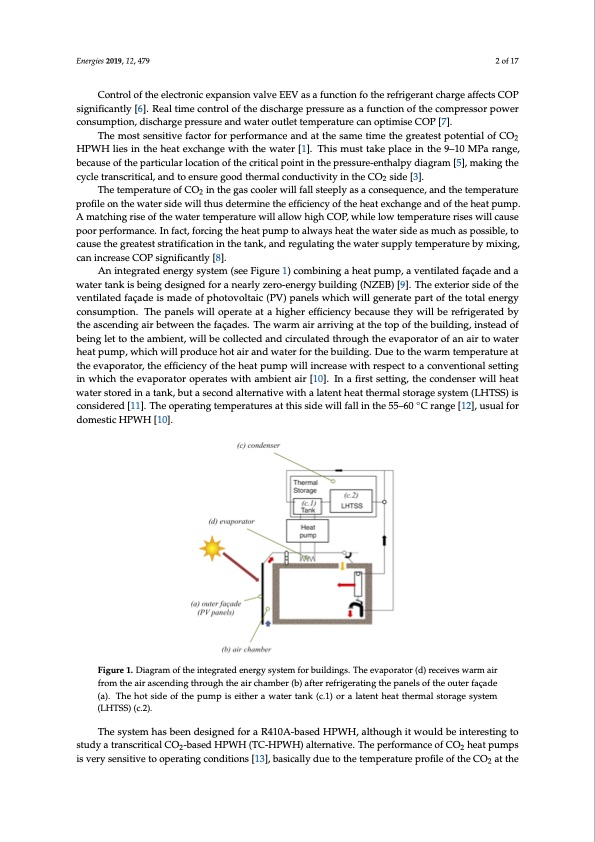

Energies 2019, 12, 479 2 of 17 Control of the electronic expansion valve EEV as a function fo the refrigerant charge affects COP significantly [6]. Real time control of the discharge pressure as a function of the compressor power consumption, discharge pressure and water outlet temperature can optimise COP [7]. The most sensitive factor for performance and at the same time the greatest potential of CO2 HPWH lies in the heat exchange with the water [1]. This must take place in the 9–10 MPa range, because of the particular location of the critical point in the pressure-enthalpy diagram [5], making the cycle transcritical, and to ensure good thermal conductivity in the CO2 side [3]. The temperature of CO2 in the gas cooler will fall steeply as a consequence, and the temperature profile on the water side will thus determine the efficiency of the heat exchange and of the heat pump. A matching rise of the water temperature will allow high COP, while low temperature rises will cause poor performance. In fact, forcing the heat pump to always heat the water side as much as possible, to cause the greatest stratification in the tank, and regulating the water supply temperature by mixing, can increase COP significantly [8]. An integrated energy system (see Figure 1) combining a heat pump, a ventilated façade and a water tank is being designed for a nearly zero-energy building (NZEB) [9]. The exterior side of the ventilated façade is made of photovoltaic (PV) panels which will generate part of the total energy consumption. The panels will operate at a higher efficiency because they will be refrigerated by the ascending air between the façades. The warm air arriving at the top of the building, instead of being let to the ambient, will be collected and circulated through the evaporator of an air to water heat pump, which will produce hot air and water for the building. Due to the warm temperature at the evaporator, the efficiency of the heat pump will increase with respect to a conventional setting in which the evaporator operates with ambient air [10]. In a first setting, the condenser will heat water stored in a tank, but a second alternative with a latent heat thermal storage system (LHTSS) is considered [11]. The operating temperatures at this side will fall in the 55–60 ◦C range [12], usual for domestic HPWH [10]. Figure 1. Diagram of the integrated energy system for buildings. The evaporator (d) receives warm air from the air ascending through the air chamber (b) after refrigerating the panels of the outer façade (a). The hot side of the pump is either a water tank (c.1) or a latent heat thermal storage system (LHTSS) (c.2). The system has been designed for a R410A-based HPWH, although it would be interesting to study a transcritical CO2-based HPWH (TC-HPWH) alternative. The performance of CO2 heat pumps is very sensitive to operating conditions [13], basically due to the temperature profile of the CO2 at thePDF Image | Comparison of Transcritical CO2 and Conventional Refrigerant Heat Pump

PDF Search Title:

Comparison of Transcritical CO2 and Conventional Refrigerant Heat PumpOriginal File Name Searched:

energies-12-00479.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |