PDF Publication Title:

Text from PDF Page: 003

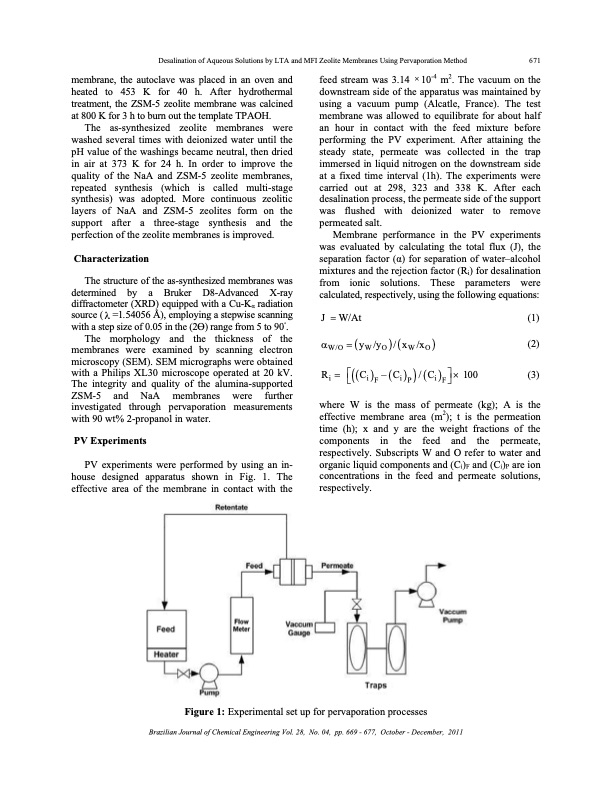

Desalination of Aqueous Solutions by LTA and MFI Zeolite Membranes Using Pervaporation Method 671 membrane, the autoclave was placed in an oven and heated to 453 K for 40 h. After hydrothermal treatment, the ZSM-5 zeolite membrane was calcined at 800 K for 3 h to burn out the template TPAOH. The as-synthesized zeolite membranes were washed several times with deionized water until the pH value of the washings became neutral, then dried in air at 373 K for 24 h. In order to improve the quality of the NaA and ZSM-5 zeolite membranes, repeated synthesis (which is called multi-stage synthesis) was adopted. More continuous zeolitic layers of NaA and ZSM-5 zeolites form on the support after a three-stage synthesis and the perfection of the zeolite membranes is improved. Characterization The structure of the as-synthesized membranes was determined by a Bruker D8-Advanced X-ray diffractometer (XRD) equipped with a Cu-Kα radiation source ( λ =1.54056 Å), employing a stepwise scanning with a step size of 0.05 in the (2Ө) range from 5 to 90◦. The morphology and the thickness of the membranes were examined by scanning electron microscopy (SEM). SEM micrographs were obtained with a Philips XL30 microscope operated at 20 kV. The integrity and quality of the alumina-supported ZSM-5 and NaA membranes were further investigated through pervaporation measurements with 90 wt% 2-propanol in water. PV Experiments PV experiments were performed by using an in- house designed apparatus shown in Fig. 1. The effective area of the membrane in contact with the feed stream was 3.14 × 10-4 m2. The vacuum on the downstream side of the apparatus was maintained by using a vacuum pump (Alcatle, France). The test membrane was allowed to equilibrate for about half an hour in contact with the feed mixture before performing the PV experiment. After attaining the steady state, permeate was collected in the trap immersed in liquid nitrogen on the downstream side at a fixed time interval (1h). The experiments were carried out at 298, 323 and 338 K. After each desalination process, the permeate side of the support was flushed with deionized water to remove permeated salt. Membrane performance in the PV experiments was evaluated by calculating the total flux (J), the separation factor (α) for separation of water–alcohol mixtures and the rejection factor (Ri) for desalination from ionic solutions. These parameters were calculated, respectively, using the following equations: J =W/At (1) αW/O = (yW /yO )/(xW /xO ) (2) Ri = ⎡((Ci) –(Ci) )/(Ci) ⎤× 100 (3) ⎣FPF⎦ where W is the mass of permeate (kg); A is the effective membrane area (m2); t is the permeation time (h); x and y are the weight fractions of the components in the feed and the permeate, respectively. Subscripts W and O refer to water and organic liquid components and (Ci)F and (Ci)P are ion concentrations in the feed and permeate solutions, respectively. Figure 1: Experimental set up for pervaporation processes Brazilian Journal of Chemical Engineering Vol. 28, No. 04, pp. 669 - 677, October - December, 2011PDF Image | DESALINATION OF AQUEOUS SOLUTIONS ZEOLITE MEMBRANES

PDF Search Title:

DESALINATION OF AQUEOUS SOLUTIONS ZEOLITE MEMBRANESOriginal File Name Searched:

PCZPTXXvZ6pQgGbDbcz9VXd.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |