PDF Publication Title:

Text from PDF Page: 019

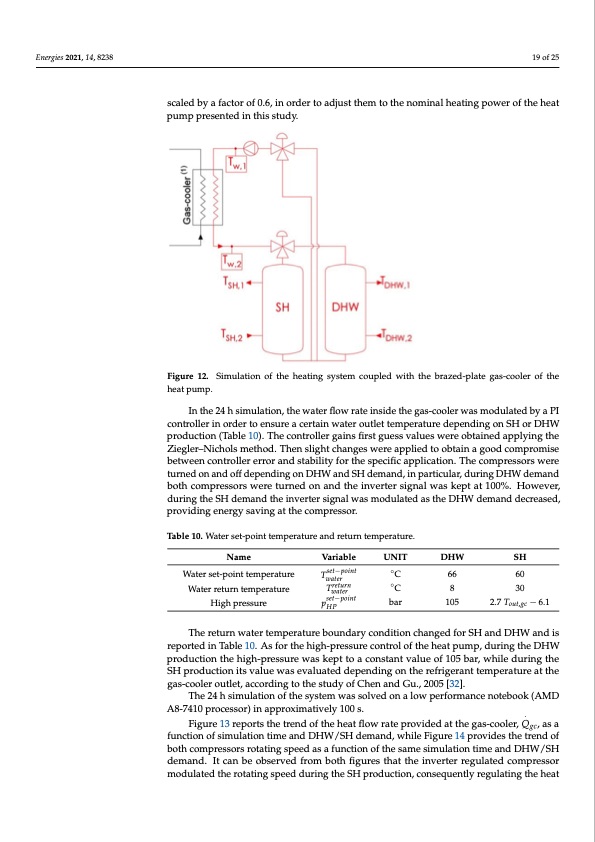

Energies 2021, 14, 8238 19 of 25 scaled by a factor of 0.6, in order to adjust them to the nominal heating power of the heat pump presented in this study. Figure 12. Simulation of the heating system coupled with the brazed-plate gas-cooler of the heat pump. In the 24 h simulation, the water flow rate inside the gas-cooler was modulated by a PI controller in order to ensure a certain water outlet temperature depending on SH or DHW production (Table 10). The controller gains first guess values were obtained applying the Ziegler–Nichols method. Then slight changes were applied to obtain a good compromise between controller error and stability for the specific application. The compressors were turned on and off depending on DHW and SH demand, in particular, during DHW demand both compressors were turned on and the inverter signal was kept at 100%. However, during the SH demand the inverter signal was modulated as the DHW demand decreased, providing energy saving at the compressor. Table 10. Water set-point temperature and return temperature. Name Water set-point temperature Water return temperature High pressure Variable Tset−point water Treturn water pset−point HP UNIT DHW ◦C 66 ◦C 8 bar 105 SH 60 30 2.7 Tout,gc − 6.1 The return water temperature boundary condition changed for SH and DHW and is reported in Table 10. As for the high-pressure control of the heat pump, during the DHW production the high-pressure was kept to a constant value of 105 bar, while during the SH production its value was evaluated depending on the refrigerant temperature at the gas-cooler outlet, according to the study of Chen and Gu., 2005 [32]. The 24 h simulation of the system was solved on a low performance notebook (AMD A8-7410 processor) in approximatively 100 s. . Figure 13 reports the trend of the heat flow rate provided at the gas-cooler, Qgc, as a function of simulation time and DHW/SH demand, while Figure 14 provides the trend of both compressors rotating speed as a function of the same simulation time and DHW/SH demand. It can be observed from both figures that the inverter regulated compressor modulated the rotating speed during the SH production, consequently regulating the heatPDF Image | Dynamic Modelling and Validation of an Air-to-Water Reversible R744

PDF Search Title:

Dynamic Modelling and Validation of an Air-to-Water Reversible R744Original File Name Searched:

Artuso2021dma_publisert.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |