PDF Publication Title:

Text from PDF Page: 016

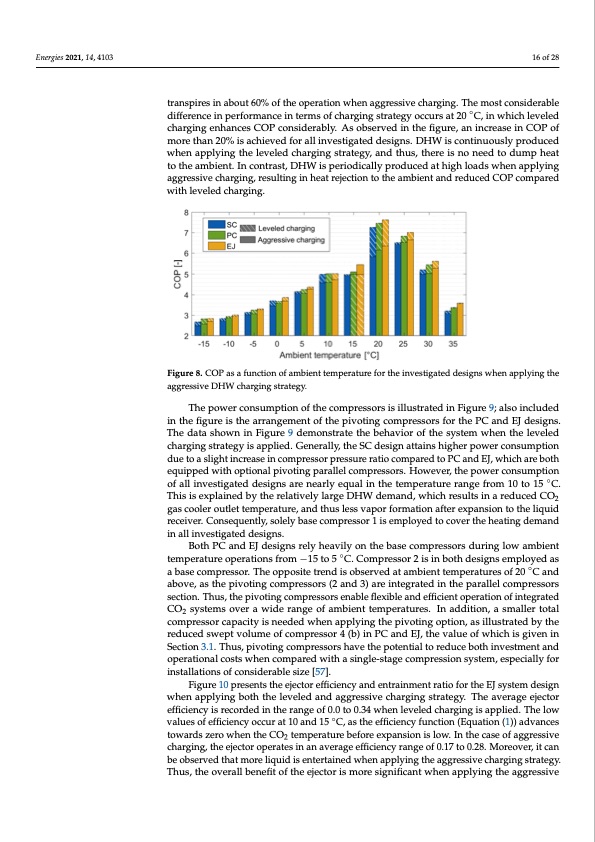

Energies 2021, 14, 4103 16 of 28 transpires in about 60% of the operation when aggressive charging. The most considerable difference in performance in terms of charging strategy occurs at 20 ◦C, in which leveled charging enhances COP considerably. As observed in the figure, an increase in COP of more than 20% is achieved for all investigated designs. DHW is continuously produced when applying the leveled charging strategy, and thus, there is no need to dump heat to the ambient. In contrast, DHW is periodically produced at high loads when applying aggressive charging, resulting in heat rejection to the ambient and reduced COP compared with leveled charging. Figure 8. COP as a function of ambient temperature for the investigated designs when applying the aggressive DHW charging strategy. The power consumption of the compressors is illustrated in Figure 9; also included in the figure is the arrangement of the pivoting compressors for the PC and EJ designs. The data shown in Figure 9 demonstrate the behavior of the system when the leveled charging strategy is applied. Generally, the SC design attains higher power consumption due to a slight increase in compressor pressure ratio compared to PC and EJ, which are both equipped with optional pivoting parallel compressors. However, the power consumption of all investigated designs are nearly equal in the temperature range from 10 to 15 ◦C. This is explained by the relatively large DHW demand, which results in a reduced CO2 gas cooler outlet temperature, and thus less vapor formation after expansion to the liquid receiver. Consequently, solely base compressor 1 is employed to cover the heating demand in all investigated designs. Both PC and EJ designs rely heavily on the base compressors during low ambient temperature operations from −15 to 5 ◦C. Compressor 2 is in both designs employed as a base compressor. The opposite trend is observed at ambient temperatures of 20 ◦C and above, as the pivoting compressors (2 and 3) are integrated in the parallel compressors section. Thus, the pivoting compressors enable flexible and efficient operation of integrated CO2 systems over a wide range of ambient temperatures. In addition, a smaller total compressor capacity is needed when applying the pivoting option, as illustrated by the reduced swept volume of compressor 4 (b) in PC and EJ, the value of which is given in Section 3.1. Thus, pivoting compressors have the potential to reduce both investment and operational costs when compared with a single-stage compression system, especially for installations of considerable size [57]. Figure 10 presents the ejector efficiency and entrainment ratio for the EJ system design when applying both the leveled and aggressive charging strategy. The average ejector efficiency is recorded in the range of 0.0 to 0.34 when leveled charging is applied. The low values of efficiency occur at 10 and 15 ◦C, as the efficiency function (Equation (1)) advances towards zero when the CO2 temperature before expansion is low. In the case of aggressive charging, the ejector operates in an average efficiency range of 0.17 to 0.28. Moreover, it can be observed that more liquid is entertained when applying the aggressive charging strategy. Thus, the overall benefit of the ejector is more significant when applying the aggressivePDF Image | Evaluation of Integrated Concepts with CO2 for Heating

PDF Search Title:

Evaluation of Integrated Concepts with CO2 for HeatingOriginal File Name Searched:

energies-14-04103-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |