PDF Publication Title:

Text from PDF Page: 035

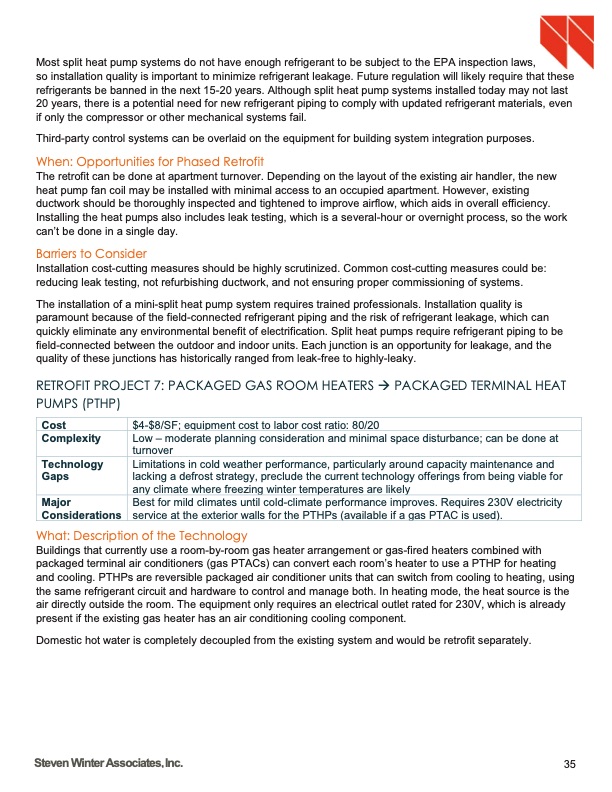

Most split heat pump systems do not have enough refrigerant to be subject to the EPA inspection laws, so installation quality is important to minimize refrigerant leakage. Future regulation will likely require that these refrigerants be banned in the next 15-20 years. Although split heat pump systems installed today may not last 20 years, there is a potential need for new refrigerant piping to comply with updated refrigerant materials, even if only the compressor or other mechanical systems fail. Third-party control systems can be overlaid on the equipment for building system integration purposes. When: Opportunities for Phased Retrofit The retrofit can be done at apartment turnover. Depending on the layout of the existing air handler, the new heat pump fan coil may be installed with minimal access to an occupied apartment. However, existing ductwork should be thoroughly inspected and tightened to improve airflow, which aids in overall efficiency. Installing the heat pumps also includes leak testing, which is a several-hour or overnight process, so the work can’t be done in a single day. Barriers to Consider Installation cost-cutting measures should be highly scrutinized. Common cost-cutting measures could be: reducing leak testing, not refurbishing ductwork, and not ensuring proper commissioning of systems. The installation of a mini-split heat pump system requires trained professionals. Installation quality is paramount because of the field-connected refrigerant piping and the risk of refrigerant leakage, which can quickly eliminate any environmental benefit of electrification. Split heat pumps require refrigerant piping to be field-connected between the outdoor and indoor units. Each junction is an opportunity for leakage, and the quality of these junctions has historically ranged from leak-free to highly-leaky. RETROFIT PROJECT 7: PACKAGED GAS ROOM HEATERS � PACKAGED TERMINAL HEAT PUMPS (PTHP) Cost Complexity Technology Gaps Major Considerations $4-$8/SF; equipment cost to labor cost ratio: 80/20 Low – moderate planning consideration and minimal space disturbance; can be done at turnover Limitations in cold weather performance, particularly around capacity maintenance and lacking a defrost strategy, preclude the current technology offerings from being viable for any climate where freezing winter temperatures are likely Best for mild climates until cold-climate performance improves. Requires 230V electricity service at the exterior walls for the PTHPs (available if a gas PTAC is used). What: Description of the Technology Buildings that currently use a room-by-room gas heater arrangement or gas-fired heaters combined with packaged terminal air conditioners (gas PTACs) can convert each room’s heater to use a PTHP for heating and cooling. PTHPs are reversible packaged air conditioner units that can switch from cooling to heating, using the same refrigerant circuit and hardware to control and manage both. In heating mode, the heat source is the air directly outside the room. The equipment only requires an electrical outlet rated for 230V, which is already present if the existing gas heater has an air conditioning cooling component. Domestic hot water is completely decoupled from the existing system and would be retrofit separately. Steven Winter Associates,Inc. 35PDF Image | HEAT PUMP RETROFIT STRATEGIES FOR MULTIFAMILY BUILDINGS

PDF Search Title:

HEAT PUMP RETROFIT STRATEGIES FOR MULTIFAMILY BUILDINGSOriginal File Name Searched:

heat-pump-retrofit-strategies-report-05082019.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |