PDF Publication Title:

Text from PDF Page: 018

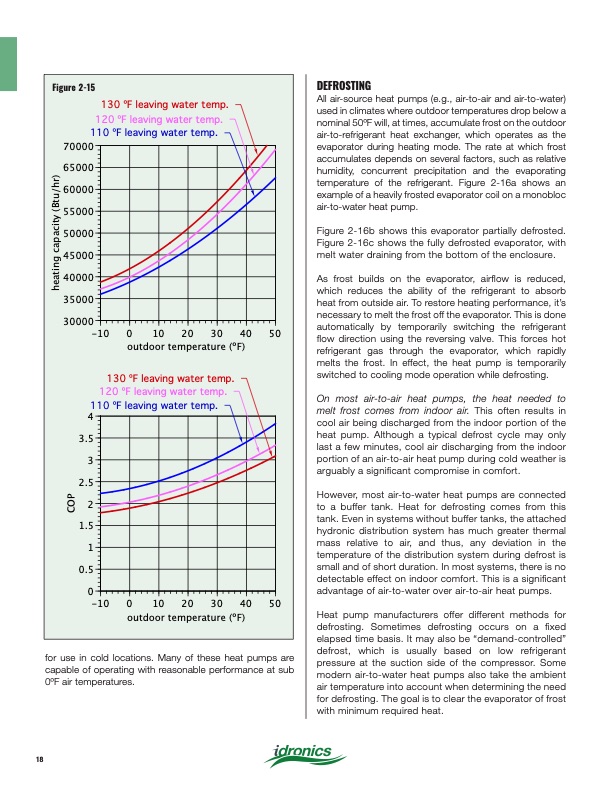

Figure 2-15 120 oF leaving water temp. 110 oF leaving water temp. 70000 65000 60000 55000 50000 45000 40000 35000 30000 -10 0 10 20 30 40 50 outdoor temperature (oF) DEFROSTING All air-source heat pumps (e.g., air-to-air and air-to-water) used in climates where outdoor temperatures drop below a nominal 50oF will, at times, accumulate frost on the outdoor air-to-refrigerant heat exchanger, which operates as the evaporator during heating mode. The rate at which frost accumulates depends on several factors, such as relative humidity, concurrent precipitation and the evaporating temperature of the refrigerant. Figure 2-16a shows an example of a heavily frosted evaporator coil on a monobloc air-to-water heat pump. Figure 2-16b shows this evaporator partially defrosted. Figure 2-16c shows the fully defrosted evaporator, with melt water draining from the bottom of the enclosure. As frost builds on the evaporator, airflow is reduced, which reduces the ability of the refrigerant to absorb heat from outside air. To restore heating performance, it’s necessary to melt the frost off the evaporator. This is done automatically by temporarily switching the refrigerant flow direction using the reversing valve. This forces hot refrigerant gas through the evaporator, which rapidly melts the frost. In effect, the heat pump is temporarily switched to cooling mode operation while defrosting. On most air-to-air heat pumps, the heat needed to melt frost comes from indoor air. This often results in cool air being discharged from the indoor portion of the heat pump. Although a typical defrost cycle may only last a few minutes, cool air discharging from the indoor portion of an air-to-air heat pump during cold weather is arguably a significant compromise in comfort. However, most air-to-water heat pumps are connected to a buffer tank. Heat for defrosting comes from this tank. Even in systems without buffer tanks, the attached hydronic distribution system has much greater thermal mass relative to air, and thus, any deviation in the temperature of the distribution system during defrost is small and of short duration. In most systems, there is no detectable effect on indoor comfort. This is a significant advantage of air-to-water over air-to-air heat pumps. Heat pump manufacturers offer different methods for defrosting. Sometimes defrosting occurs on a fixed elapsed time basis. It may also be “demand-controlled” defrost, which is usually based on low refrigerant pressure at the suction side of the compressor. Some modern air-to-water heat pumps also take the ambient air temperature into account when determining the need for defrosting. The goal is to clear the evaporator of frost with minimum required heat. 130 oF leaving water temp. 130 oF leaving water temp. 120 oF leaving water temp. 110 oF leaving water temp. 4 3.5 3 2.5 2 1.5 1 0.5 0 -10 0 10 20 30 40 50 outdoor temperature (oF) COP heating capacity (Btu/hr) for use in cold locations. Many of these heat pumps are capable of operating with reasonable performance at sub 0oF air temperatures. 18PDF Image | Heat Pump Systems 2020

PDF Search Title:

Heat Pump Systems 2020Original File Name Searched:

idronics_27_na.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |