PDF Publication Title:

Text from PDF Page: 012

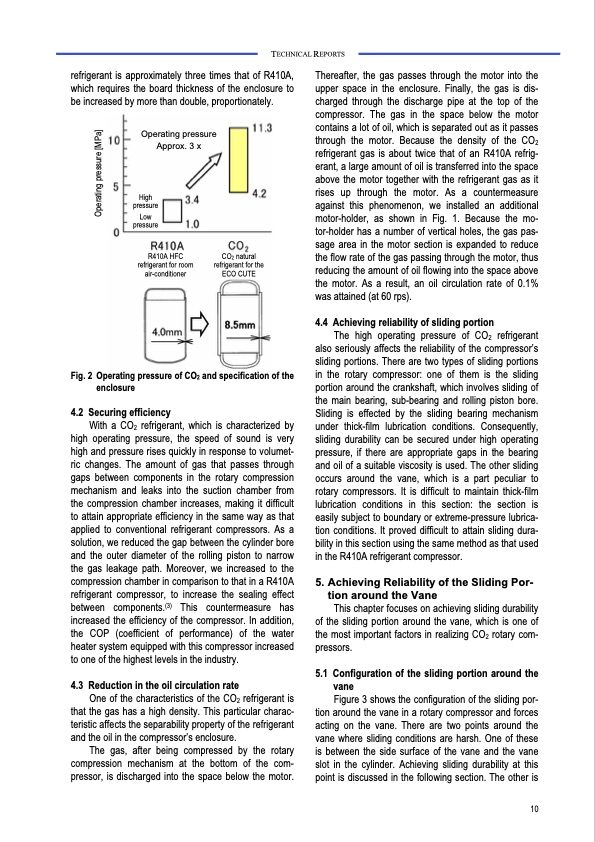

refrigerant is approximately three times that of R410A, which requires the board thickness of the enclosure to be increased by more than double, proportionately. Operating pressure Approx. 3 x Thereafter, the gas passes through the motor into the upper space in the enclosure. Finally, the gas is dis- charged through the discharge pipe at the top of the compressor. The gas in the space below the motor contains a lot of oil, which is separated out as it passes through the motor. Because the density of the CO2 refrigerant gas is about twice that of an R410A refrig- erant, a large amount of oil is transferred into the space above the motor together with the refrigerant gas as it rises up through the motor. As a countermeasure against this phenomenon, we installed an additional motor-holder, as shown in Fig. 1. Because the mo- tor-holder has a number of vertical holes, the gas pas- sage area in the motor section is expanded to reduce the flow rate of the gas passing through the motor, thus reducing the amount of oil flowing into the space above the motor. As a result, an oil circulation rate of 0.1% was attained (at 60 rps). 4.4 Achieving reliability of sliding portion The high operating pressure of CO2 refrigerant also seriously affects the reliability of the compressor’s sliding portions. There are two types of sliding portions in the rotary compressor: one of them is the sliding portion around the crankshaft, which involves sliding of the main bearing, sub-bearing and rolling piston bore. Sliding is effected by the sliding bearing mechanism under thick-film lubrication conditions. Consequently, sliding durability can be secured under high operating pressure, if there are appropriate gaps in the bearing and oil of a suitable viscosity is used. The other sliding occurs around the vane, which is a part peculiar to rotary compressors. It is difficult to maintain thick-film lubrication conditions in this section: the section is easily subject to boundary or extreme-pressure lubrica- tion conditions. It proved difficult to attain sliding dura- bility in this section using the same method as that used in the R410A refrigerant compressor. 5. Achieving Reliability of the Sliding Por- tion around the Vane This chapter focuses on achieving sliding durability of the sliding portion around the vane, which is one of the most important factors in realizing CO2 rotary com- pressors. 5.1 Configuration of the sliding portion around the vane Figure 3 shows the configuration of the sliding por- tion around the vane in a rotary compressor and forces acting on the vane. There are two points around the vane where sliding conditions are harsh. One of these is between the side surface of the vane and the vane slot in the cylinder. Achieving sliding durability at this point is discussed in the following section. The other is TECHNICAL REPORTS High pressure Low pressure R410A HFC refrigerant for room air-conditioner CO2 natural refrigerant for the ECO CUTE Fig. 2 Operating pressure of CO2 and specification of the enclosure 4.2 Securing efficiency With a CO2 refrigerant, which is characterized by high operating pressure, the speed of sound is very high and pressure rises quickly in response to volumet- ric changes. The amount of gas that passes through gaps between components in the rotary compression mechanism and leaks into the suction chamber from the compression chamber increases, making it difficult to attain appropriate efficiency in the same way as that applied to conventional refrigerant compressors. As a solution, we reduced the gap between the cylinder bore and the outer diameter of the rolling piston to narrow the gas leakage path. Moreover, we increased to the compression chamber in comparison to that in a R410A refrigerant compressor, to increase the sealing effect between components.(3) This countermeasure has increased the efficiency of the compressor. In addition, the COP (coefficient of performance) of the water heater system equipped with this compressor increased to one of the highest levels in the industry. 4.3 Reduction in the oil circulation rate One of the characteristics of the CO2 refrigerant is that the gas has a high density. This particular charac- teristic affects the separability property of the refrigerant and the oil in the compressor’s enclosure. The gas, after being compressed by the rotary compression mechanism at the bottom of the com- pressor, is discharged into the space below the motor. 10 Operating pressure [MPa]PDF Image | Heat Pump with Natural Refrigerants 3041

PDF Search Title:

Heat Pump with Natural Refrigerants 3041Original File Name Searched:

vol120.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |