PDF Publication Title:

Text from PDF Page: 018

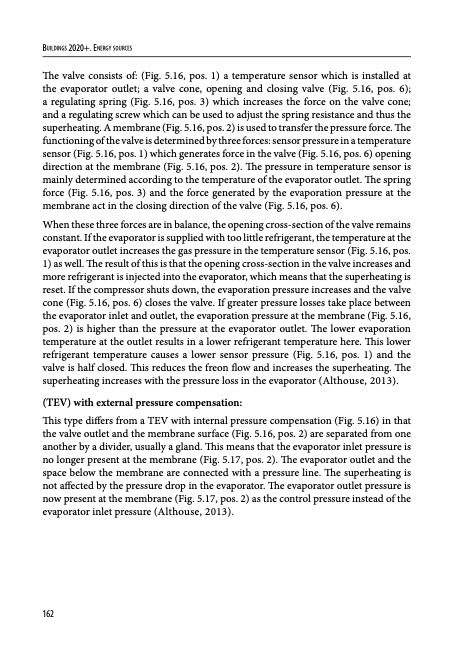

Buildings 2020+. EnErgy sourcEs The valve consists of: (Fig. 5.16, pos. 1) a temperature sensor which is installed at the evaporator outlet; a valve cone, opening and closing valve (Fig. 5.16, pos. 6); a regulating spring (Fig. 5.16, pos. 3) which increases the force on the valve cone; and a regulating screw which can be used to adjust the spring resistance and thus the superheating. A membrane (Fig. 5.16, pos. 2) is used to transfer the pressure force. The functioning of the valve is determined by three forces: sensor pressure in a temperature sensor (Fig. 5.16, pos. 1) which generates force in the valve (Fig. 5.16, pos. 6) opening direction at the membrane (Fig. 5.16, pos. 2). The pressure in temperature sensor is mainly determined according to the temperature of the evaporator outlet. The spring force (Fig. 5.16, pos. 3) and the force generated by the evaporation pressure at the membrane act in the closing direction of the valve (Fig. 5.16, pos. 6). When these three forces are in balance, the opening cross-section of the valve remains constant. If the evaporator is supplied with too little refrigerant, the temperature at the evaporator outlet increases the gas pressure in the temperature sensor (Fig. 5.16, pos. 1) as well. The result of this is that the opening cross-section in the valve increases and more refrigerant is injected into the evaporator, which means that the superheating is reset. If the compressor shuts down, the evaporation pressure increases and the valve cone (Fig. 5.16, pos. 6) closes the valve. If greater pressure losses take place between the evaporator inlet and outlet, the evaporation pressure at the membrane (Fig. 5.16, pos. 2) is higher than the pressure at the evaporator outlet. The lower evaporation temperature at the outlet results in a lower refrigerant temperature here. This lower refrigerant temperature causes a lower sensor pressure (Fig. 5.16, pos. 1) and the valve is half closed. This reduces the freon flow and increases the superheating. The superheating increases with the pressure loss in the evaporator (Althouse, 2013). (TEV) with external pressure compensation: This type differs from a TEV with internal pressure compensation (Fig. 5.16) in that the valve outlet and the membrane surface (Fig. 5.16, pos. 2) are separated from one another by a divider, usually a gland. This means that the evaporator inlet pressure is no longer present at the membrane (Fig. 5.17, pos. 2). The evaporator outlet and the space below the membrane are connected with a pressure line. The superheating is not affected by the pressure drop in the evaporator. The evaporator outlet pressure is now present at the membrane (Fig. 5.17, pos. 2) as the control pressure instead of the evaporator inlet pressure (Althouse, 2013). 162PDF Image | Heat Pumps 978-83-65596-73-4

PDF Search Title:

Heat Pumps 978-83-65596-73-4Original File Name Searched:

Buildings-2020-part2-rozdz5.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |