PDF Publication Title:

Text from PDF Page: 227

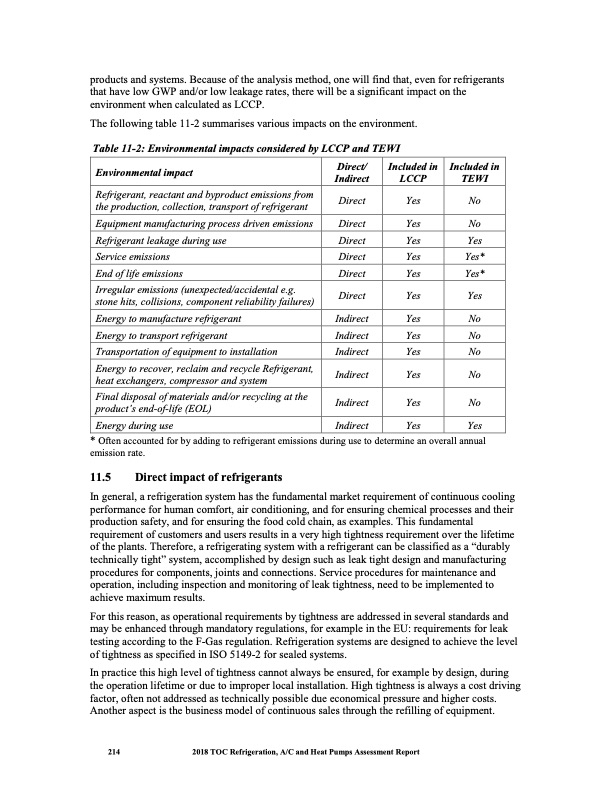

products and systems. Because of the analysis method, one will find that, even for refrigerants that have low GWP and/or low leakage rates, there will be a significant impact on the environment when calculated as LCCP. The following table 11-2 summarises various impacts on the environment. Table 11-2: Environmental impacts considered by LCCP and TEWI Environmental impact Refrigerant, reactant and byproduct emissions from the production, collection, transport of refrigerant Equipment manufacturing process driven emissions Refrigerant leakage during use Service emissions End of life emissions Irregular emissions (unexpected/accidental e.g. stone hits, collisions, component reliability failures) Energy to manufacture refrigerant Energy to transport refrigerant Transportation of equipment to installation Energy to recover, reclaim and recycle Refrigerant, heat exchangers, compressor and system Final disposal of materials and/or recycling at the product’s end-of-life (EOL) Energy during use Direct/ Indirect Direct Direct Direct Direct Direct Direct Indirect Indirect Indirect Indirect Indirect Indirect Included in LCCP Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Included in TEWI No No Yes Yes* Yes* Yes No No No No No Yes * Often accounted for by adding to refrigerant emissions during use to determine an overall annual emission rate. 11.5 Direct impact of refrigerants In general, a refrigeration system has the fundamental market requirement of continuous cooling performance for human comfort, air conditioning, and for ensuring chemical processes and their production safety, and for ensuring the food cold chain, as examples. This fundamental requirement of customers and users results in a very high tightness requirement over the lifetime of the plants. Therefore, a refrigerating system with a refrigerant can be classified as a “durably technically tight” system, accomplished by design such as leak tight design and manufacturing procedures for components, joints and connections. Service procedures for maintenance and operation, including inspection and monitoring of leak tightness, need to be implemented to achieve maximum results. For this reason, as operational requirements by tightness are addressed in several standards and may be enhanced through mandatory regulations, for example in the EU: requirements for leak testing according to the F-Gas regulation. Refrigeration systems are designed to achieve the level of tightness as specified in ISO 5149-2 for sealed systems. In practice this high level of tightness cannot always be ensured, for example by design, during the operation lifetime or due to improper local installation. High tightness is always a cost driving factor, often not addressed as technically possible due economical pressure and higher costs. Another aspect is the business model of continuous sales through the refilling of equipment. 214 2018 TOC Refrigeration, A/C and Heat Pumps Assessment ReportPDF Image | Heat Pumps Technical Options

PDF Search Title:

Heat Pumps Technical OptionsOriginal File Name Searched:

RTOC-assessment-report-2018_0.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |