PDF Publication Title:

Text from PDF Page: 014

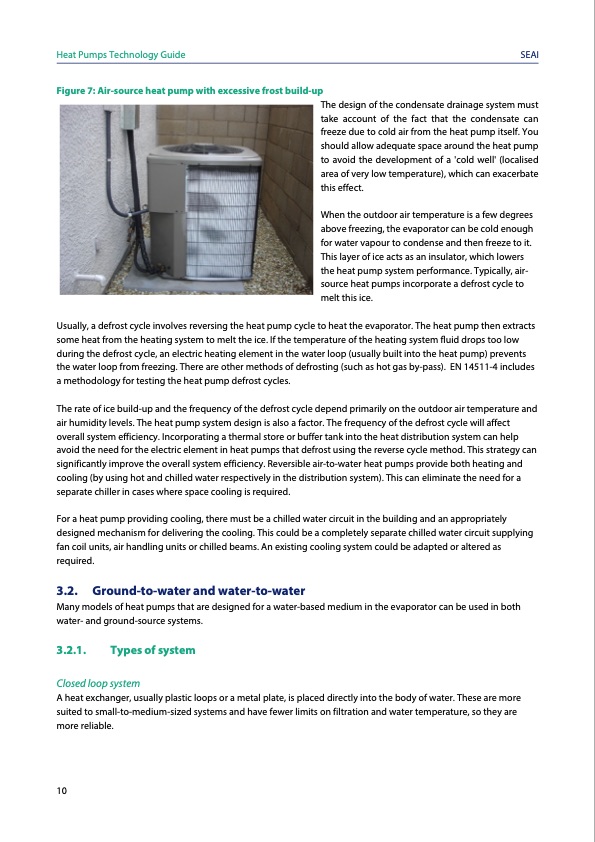

Heat Pumps Technology Guide SEAI Figure 7: Air-source heat pump with excessive frost build-up The design of the condensate drainage system must take account of the fact that the condensate can freeze due to cold air from the heat pump itself. You should allow adequate space around the heat pump to avoid the development of a 'cold well' (localised area of very low temperature), which can exacerbate this effect. When the outdoor air temperature is a few degrees above freezing, the evaporator can be cold enough for water vapour to condense and then freeze to it. This layer of ice acts as an insulator, which lowers the heat pump system performance. Typically, air- source heat pumps incorporate a defrost cycle to melt this ice. Usually, a defrost cycle involves reversing the heat pump cycle to heat the evaporator. The heat pump then extracts some heat from the heating system to melt the ice. If the temperature of the heating system fluid drops too low during the defrost cycle, an electric heating element in the water loop (usually built into the heat pump) prevents the water loop from freezing. There are other methods of defrosting (such as hot gas by-pass). EN 14511-4 includes a methodology for testing the heat pump defrost cycles. The rate of ice build-up and the frequency of the defrost cycle depend primarily on the outdoor air temperature and air humidity levels. The heat pump system design is also a factor. The frequency of the defrost cycle will affect overall system efficiency. Incorporating a thermal store or buffer tank into the heat distribution system can help avoid the need for the electric element in heat pumps that defrost using the reverse cycle method. This strategy can significantly improve the overall system efficiency. Reversible air-to-water heat pumps provide both heating and cooling (by using hot and chilled water respectively in the distribution system). This can eliminate the need for a separate chiller in cases where space cooling is required. For a heat pump providing cooling, there must be a chilled water circuit in the building and an appropriately designed mechanism for delivering the cooling. This could be a completely separate chilled water circuit supplying fan coil units, air handling units or chilled beams. An existing cooling system could be adapted or altered as required. 3.2. Ground-to-water and water-to-water Many models of heat pumps that are designed for a water-based medium in the evaporator can be used in both water- and ground-source systems. 3.2.1. Types of system Closed loop system A heat exchanger, usually plastic loops or a metal plate, is placed directly into the body of water. These are more suited to small-to-medium-sized systems and have fewer limits on filtration and water temperature, so they are more reliable. 10PDF Image | Heat Pumps Technology Guide

PDF Search Title:

Heat Pumps Technology GuideOriginal File Name Searched:

Heat-Pump-Technology-Guide.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |