PDF Publication Title:

Text from PDF Page: 031

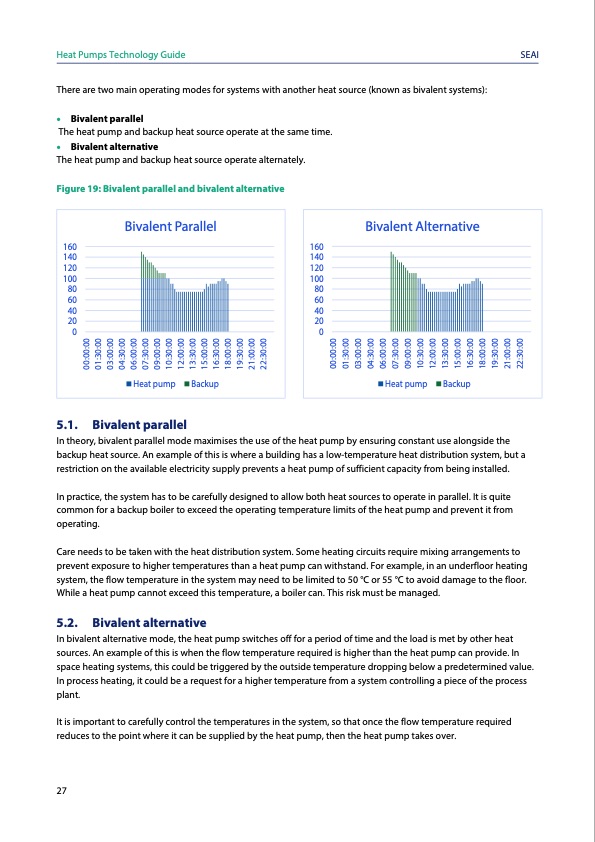

Heat Pumps Technology Guide SEAI There are two main operating modes for systems with another heat source (known as bivalent systems): • Bivalent parallel The heat pump and backup heat source operate at the same time. • Bivalent alternative The heat pump and backup heat source operate alternately. Figure 19: Bivalent parallel and bivalent alternative 160 140 120 100 80 60 40 20 0 Bivalent Alternative Heat pump Backup 160 140 120 100 80 60 40 20 0 Bivalent Parallel Heat pump Backup 5.1. Bivalent parallel In theory, bivalent parallel mode maximises the use of the heat pump by ensuring constant use alongside the backup heat source. An example of this is where a building has a low-temperature heat distribution system, but a restriction on the available electricity supply prevents a heat pump of sufficient capacity from being installed. In practice, the system has to be carefully designed to allow both heat sources to operate in parallel. It is quite common for a backup boiler to exceed the operating temperature limits of the heat pump and prevent it from operating. Care needs to be taken with the heat distribution system. Some heating circuits require mixing arrangements to prevent exposure to higher temperatures than a heat pump can withstand. For example, in an underfloor heating system, the flow temperature in the system may need to be limited to 50 °C or 55 °C to avoid damage to the floor. While a heat pump cannot exceed this temperature, a boiler can. This risk must be managed. 5.2. Bivalent alternative In bivalent alternative mode, the heat pump switches off for a period of time and the load is met by other heat sources. An example of this is when the flow temperature required is higher than the heat pump can provide. In space heating systems, this could be triggered by the outside temperature dropping below a predetermined value. In process heating, it could be a request for a higher temperature from a system controlling a piece of the process plant. It is important to carefully control the temperatures in the system, so that once the flow temperature required reduces to the point where it can be supplied by the heat pump, then the heat pump takes over. 27 00:00:00 01:30:00 03:00:00 04:30:00 06:00:00 07:30:00 09:00:00 10:30:00 12:00:00 13:30:00 15:00:00 16:30:00 18:00:00 19:30:00 21:00:00 22:30:00 00:00:00 01:30:00 03:00:00 04:30:00 06:00:00 07:30:00 09:00:00 10:30:00 12:00:00 13:30:00 15:00:00 16:30:00 18:00:00 19:30:00 21:00:00 22:30:00PDF Image | Heat Pumps Technology Guide

PDF Search Title:

Heat Pumps Technology GuideOriginal File Name Searched:

Heat-Pump-Technology-Guide.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |