PDF Publication Title:

Text from PDF Page: 005

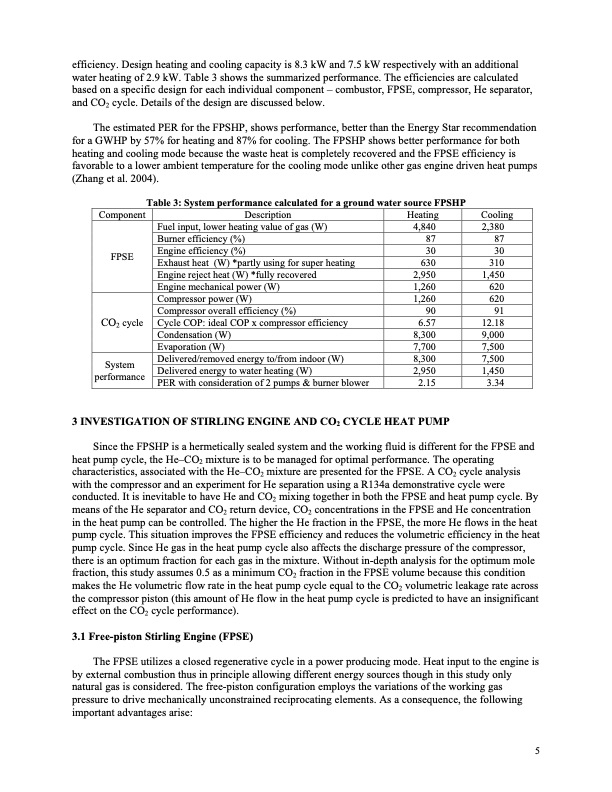

efficiency. Design heating and cooling capacity is 8.3 kW and 7.5 kW respectively with an additional water heating of 2.9 kW. Table 3 shows the summarized performance. The efficiencies are calculated based on a specific design for each individual component – combustor, FPSE, compressor, He separator, and CO2 cycle. Details of the design are discussed below. The estimated PER for the FPSHP, shows performance, better than the Energy Star recommendation for a GWHP by 57% for heating and 87% for cooling. The FPSHP shows better performance for both heating and cooling mode because the waste heat is completely recovered and the FPSE efficiency is favorable to a lower ambient temperature for the cooling mode unlike other gas engine driven heat pumps (Zhang et al. 2004). Table 3: System performance calculated for a ground water source FPSHP Component FPSE CO2 cycle System performance Description Fuel input, lower heating value of gas (W) Burner efficiency (%) Engine efficiency (%) Exhaust heat (W) *partly using for super heating Engine reject heat (W) *fully recovered Engine mechanical power (W) Compressor power (W) Compressor overall efficiency (%) Cycle COP: ideal COP x compressor efficiency Condensation (W) Evaporation (W) Delivered/removed energy to/from indoor (W) Delivered energy to water heating (W) PER with consideration of 2 pumps & burner blower Heating 4,840 87 30 630 2,950 1,260 1,260 90 6.57 8,300 7,700 8,300 2,950 2.15 Cooling 2,380 87 30 310 1,450 620 620 91 12.18 9,000 7,500 7,500 1,450 3.34 3 INVESTIGATION OF STIRLING ENGINE AND CO2 CYCLE HEAT PUMP Since the FPSHP is a hermetically sealed system and the working fluid is different for the FPSE and heat pump cycle, the He–CO2 mixture is to be managed for optimal performance. The operating characteristics, associated with the He–CO2 mixture are presented for the FPSE. A CO2 cycle analysis with the compressor and an experiment for He separation using a R134a demonstrative cycle were conducted. It is inevitable to have He and CO2 mixing together in both the FPSE and heat pump cycle. By means of the He separator and CO2 return device, CO2 concentrations in the FPSE and He concentration in the heat pump can be controlled. The higher the He fraction in the FPSE, the more He flows in the heat pump cycle. This situation improves the FPSE efficiency and reduces the volumetric efficiency in the heat pump cycle. Since He gas in the heat pump cycle also affects the discharge pressure of the compressor, there is an optimum fraction for each gas in the mixture. Without in-depth analysis for the optimum mole fraction, this study assumes 0.5 as a minimum CO2 fraction in the FPSE volume because this condition makes the He volumetric flow rate in the heat pump cycle equal to the CO2 volumetric leakage rate across the compressor piston (this amount of He flow in the heat pump cycle is predicted to have an insignificant effect on the CO2 cycle performance). 3.1 Free-piston Stirling Engine (FPSE) The FPSE utilizes a closed regenerative cycle in a power producing mode. Heat input to the engine is by external combustion thus in principle allowing different energy sources though in this study only natural gas is considered. The free-piston configuration employs the variations of the working gas pressure to drive mechanically unconstrained reciprocating elements. As a consequence, the following important advantages arise: 5PDF Image | HERMETIC GAS FIRED RESIDENTIAL HEAT PUMP

PDF Search Title:

HERMETIC GAS FIRED RESIDENTIAL HEAT PUMPOriginal File Name Searched:

Gas_Fired_Heat_Pump.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |