PDF Publication Title:

Text from PDF Page: 065

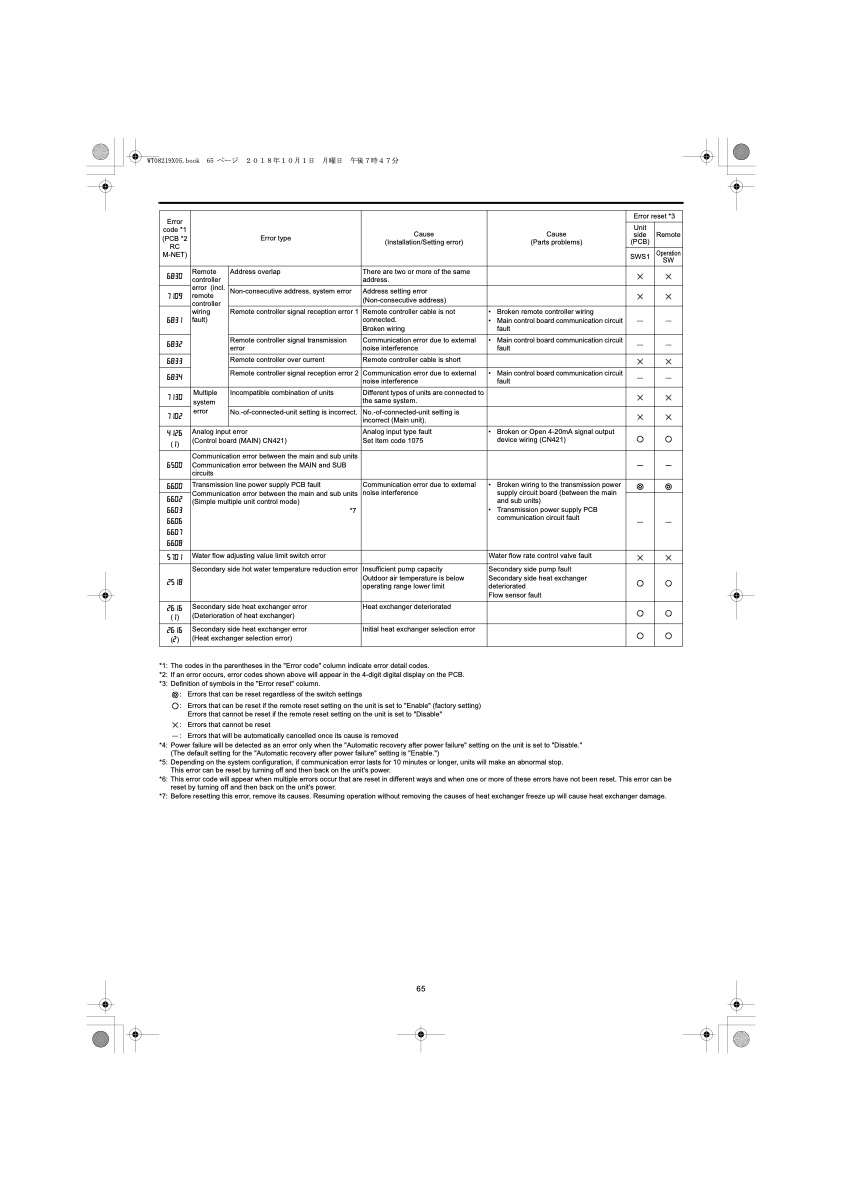

Error code *1 (PCB *2 RC M-NET) Error type Cause (Installation/Setting error) Cause (Parts problems) Error reset *3 Unit side (PCB) Remote SWS1 Operation SW 6830 Remote controller error (incl. remote controller wiring fault) Address overlap There are two or more of the same address. 7109 Non-consecutive address, system error Address setting error (Non-consecutive address) 6831 Remote controller signal reception error 1 Remote controller cable is not connected. Broken wiring • Broken remote controller wiring • Main control board communication circuit fault 6832 Remote controller signal transmission error Communication error due to external noise interference • Main control board communication circuit fault 6833 Remote controller over current Remote controller cable is short 6834 Remote controller signal reception error 2 Communication error due to external noise interference • Main control board communication circuit fault 7130 Multiple system error Incompatible combination of units Different types of units are connected to the same system. 7102 No.-of-connected-unit setting is incorrect. No.-of-connected-unit setting is incorrect (Main unit). 4126 (1) Analog input error (Control board (MAIN) CN421) Analog input type fault Set Item code 1075 • Broken or Open 4-20mA signal output device wiring (CN421) 6500 Communication error between the main and sub units Communication error between the MAIN and SUB circuits 6600 Transmission line power supply PCB fault Communication error between the main and sub units (Simple multiple unit control mode) *7 Communication error due to external noise interference • Broken wiring to the transmission power supply circuit board (between the main and sub units) • Transmission power supply PCB communication circuit fault 6602 6603 6606 6607 6608 5701 Water flow adjusting value limit switch error Water flow rate control valve fault 2518 Secondary side hot water temperature reduction error Insufficient pump capacity Outdoor air temperature is below operating range lower limit Secondary side pump fault Secondary side heat exchanger deteriorated Flow sensor fault 2616 (1) Secondary side heat exchanger error (Deterioration of heat exchanger) Heat exchanger deteriorated 2616 (2) Secondary side heat exchanger error (Heat exchanger selection error) Initial heat exchanger selection error *1: The codes in the parentheses in the "Error code" column indicate error detail codes. *2: If an error occurs, error codes shown above will appear in the 4-digit digital display on the PCB. *3: Definition of symbols in the "Error reset" column. : Errors that can be reset regardless of the switch settings : Errors that can be reset if the remote reset setting on the unit is set to "Enable" (factory setting) Errors that cannot be reset if the remote reset setting on the unit is set to "Disable" : Errors that cannot be reset : Errors that will be automatically cancelled once its cause is removed *4: Power failure will be detected as an error only when the "Automatic recovery after power failure" setting on the unit is set to "Disable." (The default setting for the "Automatic recovery after power failure" setting is "Enable.") *5: Depending on the system configuration, if communication error lasts for 10 minutes or longer, units will make an abnormal stop. This error can be reset by turning off and then back on the unit's power. *6: This error code will appear when multiple errors occur that are reset in different ways and when one or more of these errors have not been reset. This error can be reset by turning off and then back on the unit's power. *7: Before resetting this error, remove its causes. Resuming operation without removing the causes of heat exchanger freeze up will cause heat exchanger damage. 65PDF Image | QAHV-N560YA-HPB

PDF Search Title:

QAHV-N560YA-HPBOriginal File Name Searched:

IBIM_WT08219X05_QAHV_N560YA_HPB_ML.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |