PDF Publication Title:

Text from PDF Page: 009

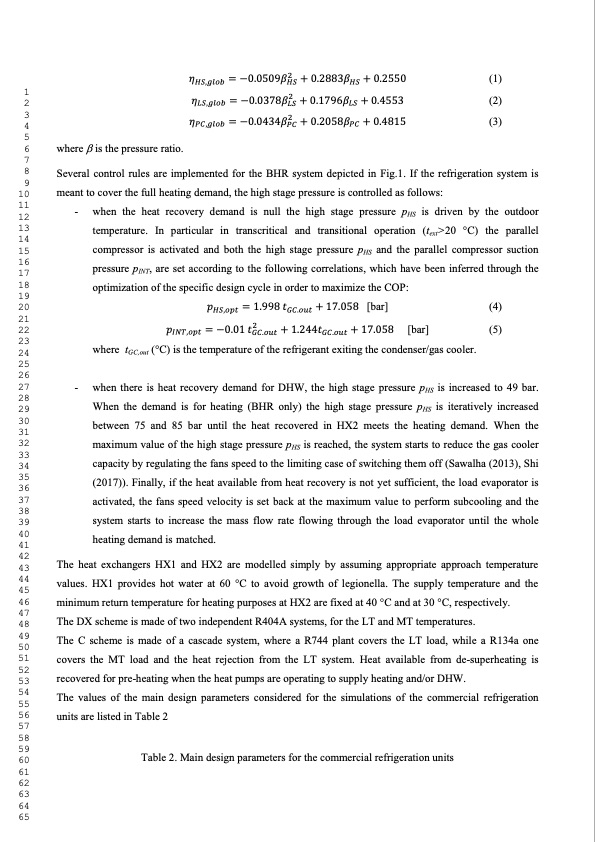

1 2 3 4 56 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 (1) (2) (3) where is the pressure ratio. Several control rules are implemented for the BHR system depicted in Fig.1. If the refrigeration system is meant to cover the full heating demand, the high stage pressure is controlled as follows: - when the heat recovery demand is null the high stage pressure pHS is driven by the outdoor temperature. In particular in transcritical and transitional operation (text>20 °C) the parallel compressor is activated and both the high stage pressure pHS and the parallel compressor suction pressure pINT, are set according to the following correlations, which have been inferred through the optimization of the specific design cycle in order to maximize the COP: [bar] (4) [bar] (5) where t when there is heat recovery demand for DHW, the high stage pressure pHS is increased to 49 bar. When the demand is for heating (BHR only) the high stage pressure p is iteratively increased HS between 75 and 85 bar until the heat recovered in HX2 meets the heating demand. When the maximum value of the high stage pressure pHS is reached, the system starts to reduce the gas cooler capacity by regulating the fans speed to the limiting case of switching them off (Sawalha (2013), Shi (2017)). Finally, if the heat available from heat recovery is not yet sufficient, the load evaporator is activated, the fans speed velocity is set back at the maximum value to perform subcooling and the system starts to increase the mass flow rate flowing through the load evaporator until the whole heating demand is matched. - GC,out (°C) is the temperature of the refrigerant exiting the condenser/gas cooler. The heat exchangers HX1 and HX2 are modelled simply by assuming appropriate approach temperature values. HX1 provides hot water at 60 °C to avoid growth of legionella. The supply temperature and the minimum return temperature for heating purposes at HX2 are fixed at 40 °C and at 30 °C, respectively. The DX scheme is made of two independent R404A systems, for the LT and MT temperatures. The C scheme is made of a cascade system, where a R744 plant covers the LT load, while a R134a one covers the MT load and the heat rejection from the LT system. Heat available from de-superheating is recovered for pre-heating when the heat pumps are operating to supply heating and/or DHW. The values of the main design parameters considered for the simulations of the commercial refrigeration units are listed in Table 2 Table 2. Main design parameters for the commercial refrigeration unitsPDF Image | R744 BOOSTER INTEGRATED SYSTEM

PDF Search Title:

R744 BOOSTER INTEGRATED SYSTEMOriginal File Name Searched:

rj34_sub.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |