PDF Publication Title:

Text from PDF Page: 004

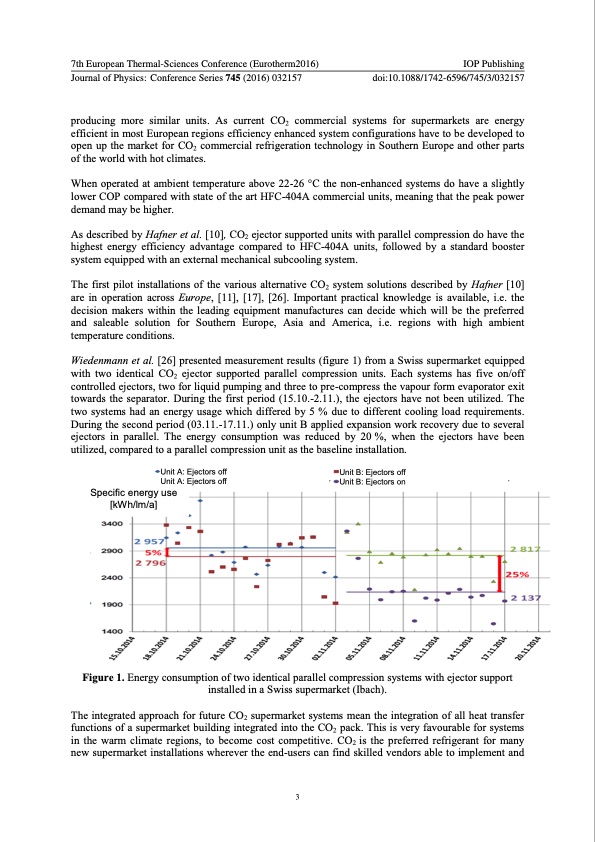

7th European Thermal-Sciences Conference (Eurotherm2016) IOP Publishing Journal of Physics: Conference Series 745 (2016) 032157 doi:10.1088/1742-6596/745/3/032157 producing more similar units. As current CO2 commercial systems for supermarkets are energy efficient in most European regions efficiency enhanced system configurations have to be developed to open up the market for CO2 commercial refrigeration technology in Southern Europe and other parts of the world with hot climates. When operated at ambient temperature above 22-26 °C the non-enhanced systems do have a slightly lower COP compared with state of the art HFC-404A commercial units, meaning that the peak power demand may be higher. As described by Hafner et al. [10], CO2 ejector supported units with parallel compression do have the highest energy efficiency advantage compared to HFC-404A units, followed by a standard booster system equipped with an external mechanical subcooling system. The first pilot installations of the various alternative CO2 system solutions described by Hafner [10] are in operation across Europe, [11], [17], [26]. Important practical knowledge is available, i.e. the decision makers within the leading equipment manufactures can decide which will be the preferred and saleable solution for Southern Europe, Asia and America, i.e. regions with high ambient temperature conditions. Wiedenmann et al. [26] presented measurement results (figure 1) from a Swiss supermarket equipped with two identical CO2 ejector supported parallel compression units. Each systems has five on/off controlled ejectors, two for liquid pumping and three to pre-compress the vapour form evaporator exit towards the separator. During the first period (15.10.-2.11.), the ejectors have not been utilized. The two systems had an energy usage which differed by 5 % due to different cooling load requirements. During the second period (03.11.-17.11.) only unit B applied expansion work recovery due to several ejectors in parallel. The energy consumption was reduced by 20 %, when the ejectors have been utilized, compared to a parallel compression unit as the baseline installation. Unit A: Ejectors off Unit A: Ejectors off Specific energy use [kWh/lm/a] Figure 1. Energy consumption of two identical parallel compression systems with ejector support installed in a Swiss supermarket (Ibach). The integrated approach for future CO2 supermarket systems mean the integration of all heat transfer functions of a supermarket building integrated into the CO2 pack. This is very favourable for systems in the warm climate regions, to become cost competitive. CO2 is the preferred refrigerant for many new supermarket installations wherever the end-users can find skilled vendors able to implement and 3 Unit B: Ejectors off Unit B: Ejectors onPDF Image | R744 ejector technology

PDF Search Title:

R744 ejector technologyOriginal File Name Searched:

Hafner_2016-745_032157.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |