PDF Publication Title:

Text from PDF Page: 013

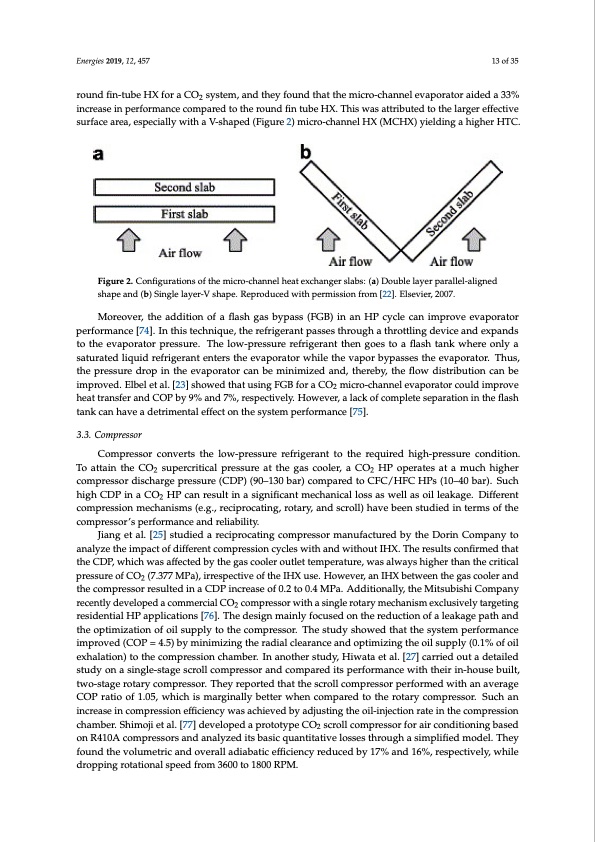

Energies 2019, 12, 457 13 of 35 round fin-tube HX for a CO2 system, and they found that the micro-channel evaporator aided a 33% increase in performance compared to the round fin tube HX. This was attributed to the larger effective sEunerrfgaicese2a01re9,a1,2e, sxpFeOcRiaPlElyERwRitEhVIaEWV-shaped (Figure 2) micro-channel HX (MCHX) yielding a higher11HoTf C33. Figure 2. Configurations of the micro-channel heat exchanger slabs: (a) Double layer parallel-aligned Figure 2. Configurations of the micro-channel heat exchanger slabs: (a) Double layer parallel-aligned shape and (b) Single layer-V shape. Reproduced with permission from [22]. Elsevier, 2007. shape and (b) Single layer-V shape. Reproduced with permission from [22]. Elsevier, 2007. Moreover, the addition of a flash gas bypass (FGB) in an HP cycle can improve evaporator Moreover, the addition of a flash gas bypass (FGB) in an HP cycle can improve evaporator performance [74]. In this technique, the refrigerant passes through a throttling device and expands performance [74]. In this technique, the refrigerant passes through a throttling device and expands to the evaporator pressure. The low-pressure refrigerant then goes to a flash tank where only a to the evaporator pressure. The low-pressure refrigerant then goes to a flash tank where only a saturated liquid refrigerant enters the evaporator while the vapor bypasses the evaporator. Thus, saturated liquid refrigerant enters the evaporator while the vapor bypasses the evaporator. Thus, the the pressure drop in the evaporator can be minimized and, thereby, the flow distribution can be pressure drop in the evaporator can be minimized and, thereby, the flow distribution can be improved. Elbel et al. [23] showed that using FGB for a CO2 micro-channel evaporator could improve improved. Elbel et al. [23] showed that using FGB for a CO2 micro-channel evaporator could improve heat transfer and COP by 9% and 7%, respectively. However, a lack of complete separation in the flash heat transfer and COP by 9% and 7%, respectively. However, a lack of complete separation in the tank can have a detrimental effect on the system performance [75]. flash tank can have a detrimental effect on the system performance [75]. 3.3. Compressor 3.3. Compressor Compressor converts the low-pressure refrigerant to the required high-pressure condition. Compressor converts the low-pressure refrigerant to the required high-pressure condition. To To attain the CO2 supercritical pressure at the gas cooler, a CO2 HP operates at a much higher attain the CO2 supercritical pressure at the gas cooler, a CO2 HP operates at a much higher compressor compressor discharge pressure (CDP) (90–130 bar) compared to CFC/HFC HPs (10–40 bar). Such discharge pressure (CDP) (90-130 bar) compared to CFC/HFC HPs (10–40 bar). Such high CDP in a high CDP in a CO2 HP can result in a significant mechanical loss as well as oil leakage. Different CO2 HP can result in a significant mechanical loss as well as oil leakage. Different compression compression mechanisms (e.g., reciprocating, rotary, and scroll) have been studied in terms of the mechanisms (e.g., reciprocating, rotary, and scroll) have been studied in terms of the compressor’s compressor’s performance and reliability. performance and reliability. Jiang et al. [25] studied a reciprocating compressor manufactured by the Dorin Company to Jiang et al. [25] studied a reciprocating compressor manufactured by the Dorin Company to analyze the impact of different compression cycles with and without IHX. The results confirmed that analyze the impact of different compression cycles with and without IHX. The results confirmed that the CDP, which was affected by the gas cooler outlet temperature, was always higher than the critical the CDP, which was affected by the gas cooler outlet temperature, was always higher than the critical pressure of CO2 (7.377 MPa), irrespective of the IHX use. However, an IHX between the gas cooler and pressure of CO2 (7.377 MPa), irrespective of the IHX use. However, an IHX between the gas cooler the compressor resulted in a CDP increase of 0.2 to 0.4 MPa. Additionally, the Mitsubishi Company and the compressor resulted in a CDP increase of 0.2 to 0.4 MPa. Additionally, the Mitsubishi recently developed a commercial CO2 compressor with a single rotary mechanism exclusively targeting Company recently developed a commercial CO2 compressor with a single rotary mechanism residential HP applications [76]. The design mainly focused on the reduction of a leakage path and exclusively targeting residential HP applications [76]. The design mainly focused on the reduction of the optimization of oil supply to the compressor. The study showed that the system performance a leakage path and the optimization of oil supply to the compressor. The study showed that the improved (COP = 4.5) by minimizing the radial clearance and optimizing the oil supply (0.1% of oil system performance improved (COP = 4.5) by minimizing the radial clearance and optimizing the oil exhalation) to the compression chamber. In another study, Hiwata et al. [27] carried out a detailed supply (0.1% of oil exhalation) to the compression chamber. In another study, Hiwata et al. [27] study on a single-stage scroll compressor and compared its performance with their in-house built, carried out a detailed study on a single-stage scroll compressor and compared its performance with two-stage rotary compressor. They reported that the scroll compressor performed with an average their in-house built, two-stage rotary compressor. They reported that the scroll compressor COP ratio of 1.05, which is marginally better when compared to the rotary compressor. Such an performed with an average COP ratio of 1.05, which is marginally better when compared to the rotary increase in compression efficiency was achieved by adjusting the oil-injection rate in the compression compressor. Such an increase in compression efficiency was achieved by adjusting the oil-injection chamber. Shimoji et al. [77] developed a prototype CO2 scroll compressor for air conditioning based rate in the compression chamber. Shimoji et al. [77] developed a prototype CO2 scroll compressor for on R410A compressors and analyzed its basic quantitative losses through a simplified model. They air conditioning based on R410A compressors and analyzed its basic quantitative losses through a found the volumetric and overall adiabatic efficiency reduced by 17% and 16%, respectively, while simplified model. They found the volumetric and overall adiabatic efficiency reduced by 17% and dropping rotational speed from 3600 to 1800 RPM. 16%, respectively, while dropping rotational speed from 3600 to 1800 RPM. In terms of system configuration, the hermetic and semi-hermetic types are the recent research focus. In a study of a semi-hermetic compressor integrated with a recuperative HX. Rozhentsev and Wang [26] reported that the HP performance was sensitive to even a marginal change in compressor efficiency and CDP (Figure 3). For example, at an optimum discharge pressure (85 bar), when the compressor efficiency decreased from 1 to 0.75, the overall HP performance reduced by 30% from thePDF Image | Recent Advances in Transcritical CO2 (R744) Heat Pump System

PDF Search Title:

Recent Advances in Transcritical CO2 (R744) Heat Pump SystemOriginal File Name Searched:

energies-12-00457.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |