PDF Publication Title:

Text from PDF Page: 015

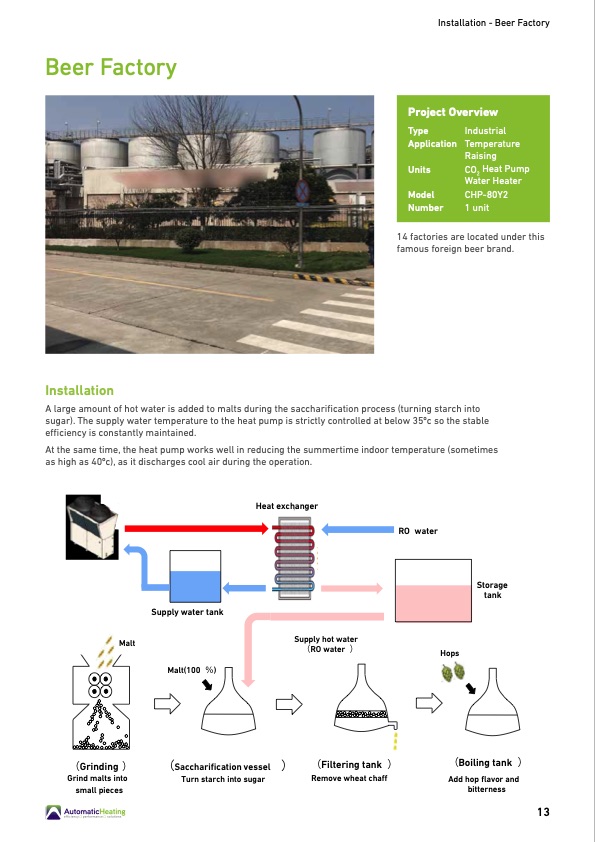

Beer Factory A large amount of hot water is added to malts during the saccharification process (turning starch into sugar). The supply water temperature to the heat pump is strictly controlled at below 35oc so the stable efficiency is constantly maintained. At the same time, the heat pump works well in reducing the summertime indoor temperature (sometimes as high as 40oc), as it discharges cool air during the operation. Installation - Beer Factory Installation Project Overview Type Application Units Model Number Industrial Temperature Raising CO2 Heat Pump Water Heater CHP-80Y2 1 unit 14 factories are located under this famous foreign beer brand. Heat exchanger Supply hot water (ROwater ) RO water Hops (Boilingtank ) Add hop flavor and bitterness Supply water tank Malt (Grinding ) Grind malts into small pieces Storage tank Malt(100 %) (Saccharification vessel ) Turn starch into sugar (Filteringtank ) Remove wheat chaff 13 12PDF Image | Revere CO2

PDF Search Title:

Revere CO2Original File Name Searched:

Revere-CO2-Heat-Pump-Package-brochure.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |