PDF Publication Title:

Text from PDF Page: 017

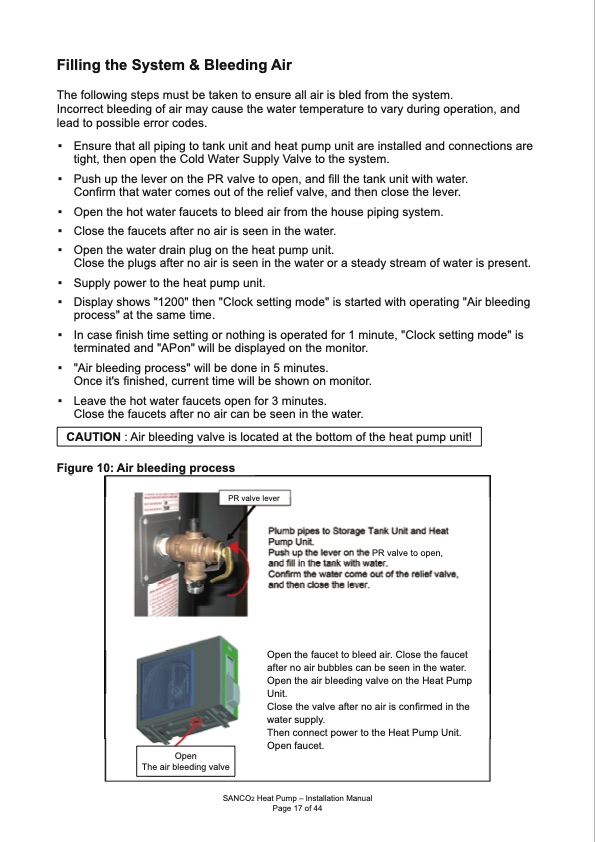

Filling the System & Bleeding Air Removing air from the system TPhleafoslloewninogtsete:ps must be taken to ensure all air is bled from the system. Incorrect bleeding of air may cause the water temperature to vary during operation, and Plumbing work should only be completed by a licensed plumber lead to possible error codes. • The following steps must be taken to ensure all air is removed from the system. ・ Ensure that all piping to tank unit and heat pump unit are installed and connections are tight, then open the Cold Water Supply Valve to the system. *Caution Incorrect removal of air may cause the water temperature to vary. • Plumb pipes to the tank unit and the heat pump unit. ・ Push up the lever on the PR valve to open, and fill the tank unit with water. • Push up the lever on the PTR valve to open, and fill the tank unit with water. Confirm that water comes out of the relief valve, and then close the lever. • Confirm that the water comes out of the relief valve and then close the lever. ・ Open the hot water faucets to bleed air from the house piping system. • Open the hot water taps in the home to remove air. ・ C• losCelotshe tfhaeucheottswaaftterrntaopasirinisthseehnominethaeftweranteor.air is confirmed in the water. • Open the water drain plug on the heat pump unit. ・ Open the water drain plug on the heat pump unit. • Close the plug after no air is confirmed in the water. Close the plugs after no air is seen in the water or a steady stream of water is present. • Connect the power to the heat pump unit. ・ Supply power to the heat pump unit. • Air removing process (Refer to figure 4) ・ Disp1l.aySswhiotcwhsin"g12to00A"irthRenm"oCvloincgkMseotdtieng mode" is started with operating "Air bleeding processL"oantgthperesasmtheeti“mUep.” and “Down” keys to switch to the “Heat Setting Mode”. 2. Pressthe“Up”or“Down”keystoswitchtothe“AirRemovingMode”andpress ・ In case finish time setting or nothing is operated for 1 minute, "Clock setting mode" is the “Enter” key. Press the “Up” keys again to display “APon”, then press the terminated and "APon" will be displayed on the monitor. “Enter” key. ・ "Air bleeding process" will be done in 5 minutes. After 5 minutes, the air removing mode will automatically finish and the display will Once it's finished, current time will be shown on monitor. show [Air ] again. ・ L•eaOvepethnetheothwoat tweartfearutcaepts ionptehnefhoorm3emtionuretems.ove air. C• losCelotshe tfhaeucheottswaaftterrntaopasirincathnebheosmeenafitnerthneowaairteisr.confirmed in the water. ng cycle. PR valve lever PR valve to open, CAUTION : Air bleeding valve is located at the bottom of the heat pump unit! If air removing mode is not completed, the system will not start the heati Figure 10: Air bleeding process Figure 4: Air removing process Open the faucet to bleed air. Close the faucet after no air bubbles can be seen in the water. Open the air bleeding valve on the Heat Pump Unit. Close the valve after no air is confirmed in the water supply. Then connect power to the Heat Pump Unit. Open faucet. Open The air bleeding valve Sanden Heat Pump – Owner’s Manual SANCO2 Heat Pump – Installation Manual Page 11 of 20 Page 17 of 44PDF Image | SANCO2 Heat Pump Water Heater R744

PDF Search Title:

SANCO2 Heat Pump Water Heater R744Original File Name Searched:

Installation_Manual_SANCO2.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |