PDF Publication Title:

Text from PDF Page: 003

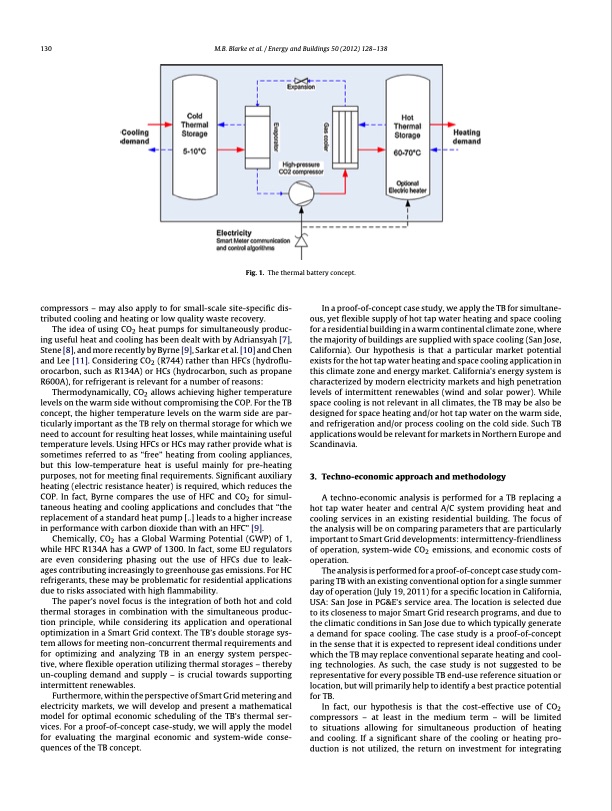

130 M.B. Blarke et al. / Energy and Buildings 50 (2012) 128–138 compressors – may also apply to for small-scale site-specific dis- tributed cooling and heating or low quality waste recovery. The idea of using CO2 heat pumps for simultaneously produc- ing useful heat and cooling has been dealt with by Adriansyah [7], Stene [8], and more recently by Byrne [9], Sarkar et al. [10] and Chen and Lee [11]. Considering CO2 (R744) rather than HFCs (hydroflu- orocarbon, such as R134A) or HCs (hydrocarbon, such as propane R600A), for refrigerant is relevant for a number of reasons: Thermodynamically, CO2 allows achieving higher temperature levels on the warm side without compromising the COP. For the TB concept, the higher temperature levels on the warm side are par- ticularly important as the TB rely on thermal storage for which we need to account for resulting heat losses, while maintaining useful temperature levels. Using HFCs or HCs may rather provide what is sometimes referred to as “free” heating from cooling appliances, but this low-temperature heat is useful mainly for pre-heating purposes, not for meeting final requirements. Significant auxiliary heating (electric resistance heater) is required, which reduces the COP. In fact, Byrne compares the use of HFC and CO2 for simul- taneous heating and cooling applications and concludes that “the replacement of a standard heat pump [..] leads to a higher increase in performance with carbon dioxide than with an HFC” [9]. Chemically, CO2 has a Global Warming Potential (GWP) of 1, while HFC R134A has a GWP of 1300. In fact, some EU regulators are even considering phasing out the use of HFCs due to leak- ages contributing increasingly to greenhouse gas emissions. For HC refrigerants, these may be problematic for residential applications due to risks associated with high flammability. The paper’s novel focus is the integration of both hot and cold thermal storages in combination with the simultaneous produc- tion principle, while considering its application and operational optimization in a Smart Grid context. The TB’s double storage sys- tem allows for meeting non-concurrent thermal requirements and for optimizing and analyzing TB in an energy system perspec- tive, where flexible operation utilizing thermal storages – thereby un-coupling demand and supply – is crucial towards supporting intermittent renewables. Furthermore, within the perspective of Smart Grid metering and electricity markets, we will develop and present a mathematical model for optimal economic scheduling of the TB’s thermal ser- vices. For a proof-of-concept case-study, we will apply the model for evaluating the marginal economic and system-wide conse- quences of the TB concept. In a proof-of-concept case study, we apply the TB for simultane- ous, yet flexible supply of hot tap water heating and space cooling for a residential building in a warm continental climate zone, where the majority of buildings are supplied with space cooling (San Jose, California). Our hypothesis is that a particular market potential exists for the hot tap water heating and space cooling application in this climate zone and energy market. California’s energy system is characterized by modern electricity markets and high penetration levels of intermittent renewables (wind and solar power). While space cooling is not relevant in all climates, the TB may be also be designed for space heating and/or hot tap water on the warm side, and refrigeration and/or process cooling on the cold side. Such TB applications would be relevant for markets in Northern Europe and Scandinavia. 3. Techno-economic approach and methodology A techno-economic analysis is performed for a TB replacing a hot tap water heater and central A/C system providing heat and cooling services in an existing residential building. The focus of the analysis will be on comparing parameters that are particularly important to Smart Grid developments: intermittency-friendliness of operation, system-wide CO2 emissions, and economic costs of operation. The analysis is performed for a proof-of-concept case study com- paring TB with an existing conventional option for a single summer day of operation (July 19, 2011) for a specific location in California, USA: San Jose in PG&E’s service area. The location is selected due to its closeness to major Smart Grid research programs, and due to the climatic conditions in San Jose due to which typically generate a demand for space cooling. The case study is a proof-of-concept in the sense that it is expected to represent ideal conditions under which the TB may replace conventional separate heating and cool- ing technologies. As such, the case study is not suggested to be representative for every possible TB end-use reference situation or location, but will primarily help to identify a best practice potential for TB. In fact, our hypothesis is that the cost-effective use of CO2 compressors – at least in the medium term – will be limited to situations allowing for simultaneous production of heating and cooling. If a significant share of the cooling or heating pro- duction is not utilized, the return on investment for integrating Fig. 1. The thermal battery concept.PDF Image | Thermal battery with CO2 compression heat pump

PDF Search Title:

Thermal battery with CO2 compression heat pumpOriginal File Name Searched:

Thermal-battery-with-CO2-compression-heat pump.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |