PDF Publication Title:

Text from PDF Page: 008

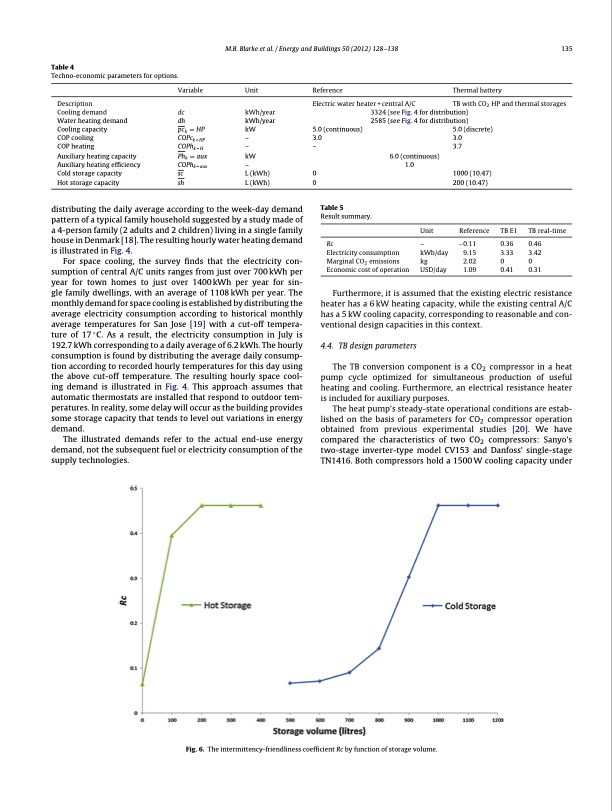

Table 4 Techno-economic parameters for options. M.B. Blarke et al. / Energy and Buildings 50 (2012) 128–138 135 Description Cooling demand Water heating demand Cooling capacity COP cooling COP heating Auxiliary heating capacity Auxiliary heating efficiency Cold storage capacity Hot storage capacity Variable dc dh pck =HP COPck = HP COPhk = H Phk = aux COPhk = aux sc sh Unit kWh/year kWh/year Reference Electric water heater + central A/C Thermal battery TB with CO2 HP and thermal storages kW – – – kW – L (kWh) 0 L (kWh) 0 5.0 (continuous) 3.0 Table 5 Result summary. Rc Electricity consumption Marginal CO2 emissions Economic cost of operation 5.0 (discrete) 3.0 3.7 1000 (10.47) 200 (10.47) Reference 3324 (see Fig. 4 for distribution) 2585 (see Fig. 4 for distribution) 6.0 (continuous) 1.0 distributing the daily average according to the week-day demand pattern of a typical family household suggested by a study made of a 4-person family (2 adults and 2 children) living in a single family house in Denmark [18]. The resulting hourly water heating demand is illustrated in Fig. 4. For space cooling, the survey finds that the electricity con- sumption of central A/C units ranges from just over 700 kWh per year for town homes to just over 1400kWh per year for sin- gle family dwellings, with an average of 1108 kWh per year. The monthly demand for space cooling is established by distributing the average electricity consumption according to historical monthly average temperatures for San Jose [19] with a cut-off tempera- ture of 17◦C. As a result, the electricity consumption in July is 192.7 kWh corresponding to a daily average of 6.2 kWh. The hourly consumption is found by distributing the average daily consump- tion according to recorded hourly temperatures for this day using the above cut-off temperature. The resulting hourly space cool- ing demand is illustrated in Fig. 4. This approach assumes that automatic thermostats are installed that respond to outdoor tem- peratures. In reality, some delay will occur as the building provides some storage capacity that tends to level out variations in energy demand. The illustrated demands refer to the actual end-use energy demand, not the subsequent fuel or electricity consumption of the supply technologies. Unit TB E1 0.36 3.33 0 0.41 TB real-time 0.46 3.42 0 0.31 – −0.11 kWh/day 9.15 kg 2.02 USD/day 1.09 Furthermore, it is assumed that the existing electric resistance heater has a 6 kW heating capacity, while the existing central A/C has a 5 kW cooling capacity, corresponding to reasonable and con- ventional design capacities in this context. 4.4. TBdesignparameters The TB conversion component is a CO2 compressor in a heat pump cycle optimized for simultaneous production of useful heating and cooling. Furthermore, an electrical resistance heater is included for auxiliary purposes. The heat pump’s steady-state operational conditions are estab- lished on the basis of parameters for CO2 compressor operation obtained from previous experimental studies [20]. We have compared the characteristics of two CO2 compressors: Sanyo’s two-stage inverter-type model CV153 and Danfoss’ single-stage TN1416. Both compressors hold a 1500 W cooling capacity under Fig. 6. The intermittency-friendliness coefficient Rc by function of storage volume.PDF Image | Thermal battery with CO2 compression heat pump

PDF Search Title:

Thermal battery with CO2 compression heat pumpOriginal File Name Searched:

Thermal-battery-with-CO2-compression-heat pump.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |