PDF Publication Title:

Text from PDF Page: 003

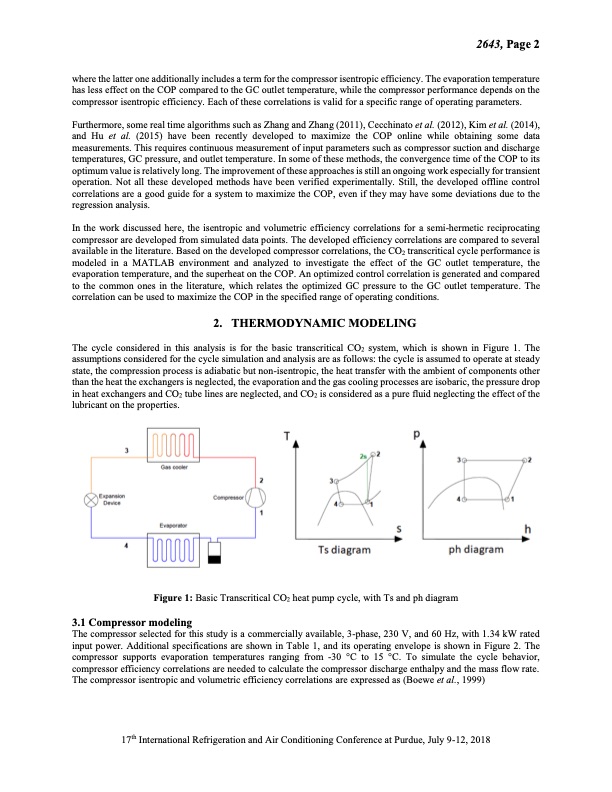

where the latter one additionally includes a term for the compressor isentropic efficiency. The evaporation temperature has less effect on the COP compared to the GC outlet temperature, while the compressor performance depends on the compressor isentropic efficiency. Each of these correlations is valid for a specific range of operating parameters. Furthermore, some real time algorithms such as Zhang and Zhang (2011), Cecchinato et al. (2012), Kim et al. (2014), and Hu et al. (2015) have been recently developed to maximize the COP online while obtaining some data measurements. This requires continuous measurement of input parameters such as compressor suction and discharge temperatures, GC pressure, and outlet temperature. In some of these methods, the convergence time of the COP to its optimum value is relatively long. The improvement of these approaches is still an ongoing work especially for transient operation. Not all these developed methods have been verified experimentally. Still, the developed offline control correlations are a good guide for a system to maximize the COP, even if they may have some deviations due to the regression analysis. In the work discussed here, the isentropic and volumetric efficiency correlations for a semi-hermetic reciprocating compressor are developed from simulated data points. The developed efficiency correlations are compared to several available in the literature. Based on the developed compressor correlations, the CO2 transcritical cycle performance is modeled in a MATLAB environment and analyzed to investigate the effect of the GC outlet temperature, the evaporation temperature, and the superheat on the COP. An optimized control correlation is generated and compared to the common ones in the literature, which relates the optimized GC pressure to the GC outlet temperature. The correlation can be used to maximize the COP in the specified range of operating conditions. 2. THERMODYNAMIC MODELING The cycle considered in this analysis is for the basic transcritical CO2 system, which is shown in Figure 1. The assumptions considered for the cycle simulation and analysis are as follows: the cycle is assumed to operate at steady state, the compression process is adiabatic but non-isentropic, the heat transfer with the ambient of components other than the heat the exchangers is neglected, the evaporation and the gas cooling processes are isobaric, the pressure drop in heat exchangers and CO2 tube lines are neglected, and CO2 is considered as a pure fluid neglecting the effect of the lubricant on the properties. Figure 1: Basic Transcritical CO2 heat pump cycle, with Ts and ph diagram 3.1 Compressor modeling The compressor selected for this study is a commercially available, 3-phase, 230 V, and 60 Hz, with 1.34 kW rated input power. Additional specifications are shown in Table 1, and its operating envelope is shown in Figure 2. The compressor supports evaporation temperatures ranging from -30 °C to 15 °C. To simulate the cycle behavior, compressor efficiency correlations are needed to calculate the compressor discharge enthalpy and the mass flow rate. The compressor isentropic and volumetric efficiency correlations are expressed as (Boewe et al., 1999) 2643, Page 2 17th International Refrigeration and Air Conditioning Conference at Purdue, July 9-12, 2018PDF Image | Transcritical CO2 Heat Pump Cycle

PDF Search Title:

Transcritical CO2 Heat Pump CycleOriginal File Name Searched:

220147355.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |