PDF Publication Title:

Text from PDF Page: 003

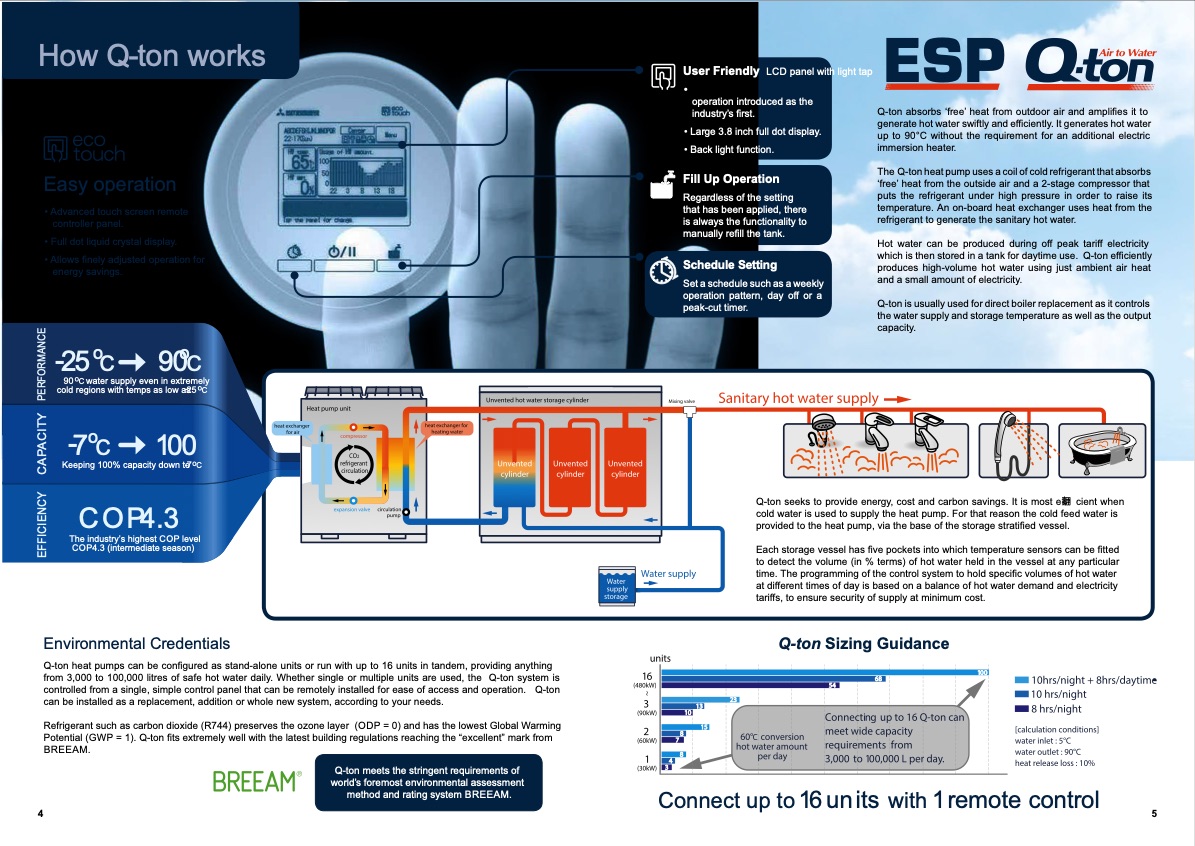

How Q-ton works Easy operation • Advanced touch screen remote controller panel. • Full dot liquid crystal display. • Allows finely adjusted operation for energy savings. -25 oC 90oC 90 oC water supply even in extremely cold regions with temps as low a-s25 oC o -7 C 100 Keeping 100% capacity down t-o7oC COP4.3 The industry’s highest COP level COP4.3 (intermediate season) Environmental Credentials Q-ton heat pumps can be configured as stand-alone units or run with up to 16 units in tandem, providing anything from 3,000 to 100,000 litres of safe hot water daily. Whether single or multiple units are used, the Q-ton system is controlled from a single, simple control panel that can be remotely installed for ease of access and operation. Q-ton can be installed as a replacement, addition or whole new system, according to your needs. Refrigerant such as carbon dioxide (R744) preserves the ozone layer (ODP = 0) and has the lowest Global Warming Potential (GWP = 1). Q-ton fits extremely well with the latest building regulations reaching the “excellent” mark from BREEAM. Q-ton meets the stringent requirements of world’s foremost environmental assessment method and rating system BREEAM. User Friendly LCD panel with light tap • operation introduced as the industry’s first. • Large 3.8 inch full dot display. • Back light function. Fill Up Operation Regardless of the setting that has been applied, there is always the functionality to manually refill the tank. Schedule Setting Set a schedule such as a weekly operation pattern, day off or a peak-cut timer. ESP Q-ton absorbs ‘free’ heat from outdoor air and amplifies it to generate hot water swiftly and efficiently. It generates hot water up to 90°C without the requirement for an additional electric immersion heater. The Q-ton heat pump uses a coil of cold refrigerant that absorbs ‘free’ heat from the outside air and a 2-stage compressor that puts the refrigerant under high pressure in order to raise its temperature. An on-board heat exchanger uses heat from the refrigerant to generate the sanitary hot water. Hot water can be produced during off peak tariff electricity which is then stored in a tank for daytime use. Q-ton efficiently produces high-volume hot water using just ambient air heat and a small amount of electricity. Q-ton is usually used for direct boiler replacement as it controls the water supply and storage temperature as well as the output capacity. Q-ton seeks to provide energy, cost and carbon savings. It is most e翿 cient when cold water is used to supply the heat pump. For that reason the cold feed water is provided to the heat pump, via the base of the storage stratified vessel. Each storage vessel has five pockets into which temperature sensors can be fitted to detect the volume (in % terms) of hot water held in the vessel at any particular time. The programming of the control system to hold specific volumes of hot water at different times of day is based on a balance of hot water demand and electricity tariffs, to ensure security of supply at minimum cost. Q-ton Sizing Guidance 45 Connect up to16units with 1remote control EFFICIENCY CAPACITY PERFORMANCEPDF Image | Using CO2 gas as a natural refrigerant Qton

PDF Search Title:

Using CO2 gas as a natural refrigerant QtonOriginal File Name Searched:

8115_1Wz_1569232602.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |