PDF Publication Title:

Text from PDF Page: 006

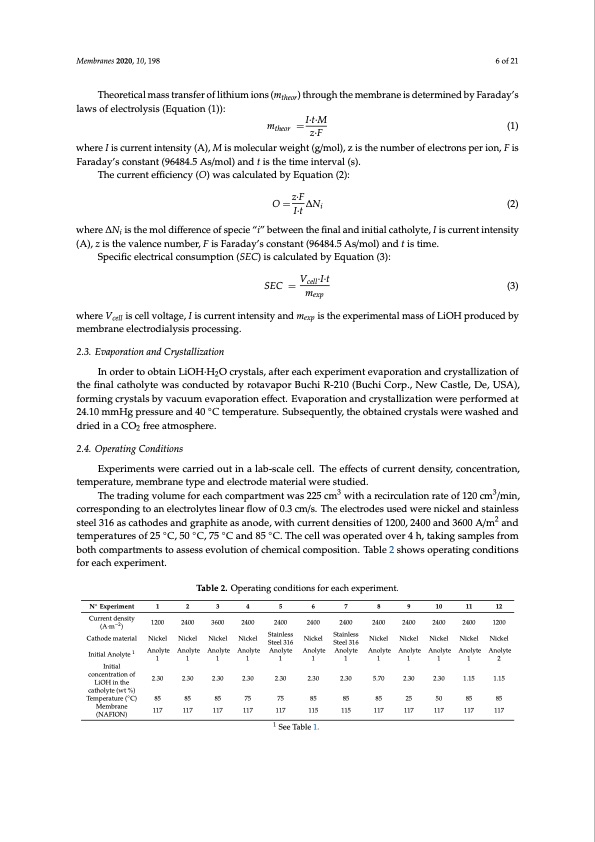

Membranes 2020, 10, 198 6 of 21 Theoretical mass transfer of lithium ions (mtheor) through the membrane is determined by Faraday’s laws of electrolysis (Equation (1)): mtheor = I·t·M (1) z·F where I is current intensity (A), M is molecular weight (g/mol), z is the number of electrons per ion, F is Faraday’s constant (96484.5 As/mol) and t is the time interval (s). The current efficiency (O) was calculated by Equation (2): O =z·F∆Ni (2) I·t where ∆Ni is the mol difference of specie “i” between the final and initial catholyte, I is current intensity (A), z is the valence number, F is Faraday’s constant (96484.5 As/mol) and t is time. Specific electrical consumption (SEC) is calculated by Equation (3): SEC = Vcell·I·t (3) mexp where Vcell is cell voltage, I is current intensity and mexp is the experimental mass of LiOH produced by membrane electrodialysis processing. 2.3. Evaporation and Crystallization In order to obtain LiOH·H2O crystals, after each experiment evaporation and crystallization of the final catholyte was conducted by rotavapor Buchi R-210 (Buchi Corp., New Castle, De, USA), forming crystals by vacuum evaporation effect. Evaporation and crystallization were performed at 24.10 mmHg pressure and 40 ◦C temperature. Subsequently, the obtained crystals were washed and dried in a CO2 free atmosphere. 2.4. Operating Conditions Experiments were carried out in a lab-scale cell. The effects of current density, concentration, temperature, membrane type and electrode material were studied. The trading volume for each compartment was 225 cm3 with a recirculation rate of 120 cm3/min, corresponding to an electrolytes linear flow of 0.3 cm/s. The electrodes used were nickel and stainless steel 316 as cathodes and graphite as anode, with current densities of 1200, 2400 and 3600 A/m2 and temperatures of 25 ◦C, 50 ◦C, 75 ◦C and 85 ◦C. The cell was operated over 4 h, taking samples from both compartments to assess evolution of chemical composition. Table 2 shows operating conditions for each experiment. Table 2. Operating conditions for each experiment. N◦Experiment 1 2 3 4 5 6 7 8 9 10 11 12 Current density (A·m−2 ) Cathode material Initial Anolyte 1 Initial concentration of LiOH in the catholyte (wt %) Temperature (◦C) Membrane (NAFION) 1200 2400 3600 2400 2400 2400 Nickel Nickel Nickel Nickel Stainless Nickel Steel 316 2400 2400 2400 2400 2400 1200 Stainless Nickel Nickel Nickel Nickel Nickel Steel 316 Anolyte Anolyte Anolyte Anolyte Anolyte Anolyte Anolyte Anolyte Anolyte Anolyte Anolyte Anolyte 111111111112 2.30 2.30 2.30 2.30 85 85 85 75 117 117 117 117 2.30 2.30 2.30 75 85 85 117 115 115 1 See Table 1. 5.70 2.30 85 25 117 117 2.30 1.15 1.15 50 85 85 117 117 117PDF Image | Battery Grade Li Hydroxide by Membrane Electrodialysis

PDF Search Title:

Battery Grade Li Hydroxide by Membrane ElectrodialysisOriginal File Name Searched:

membranes-10-00198.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |