PDF Publication Title:

Text from PDF Page: 003

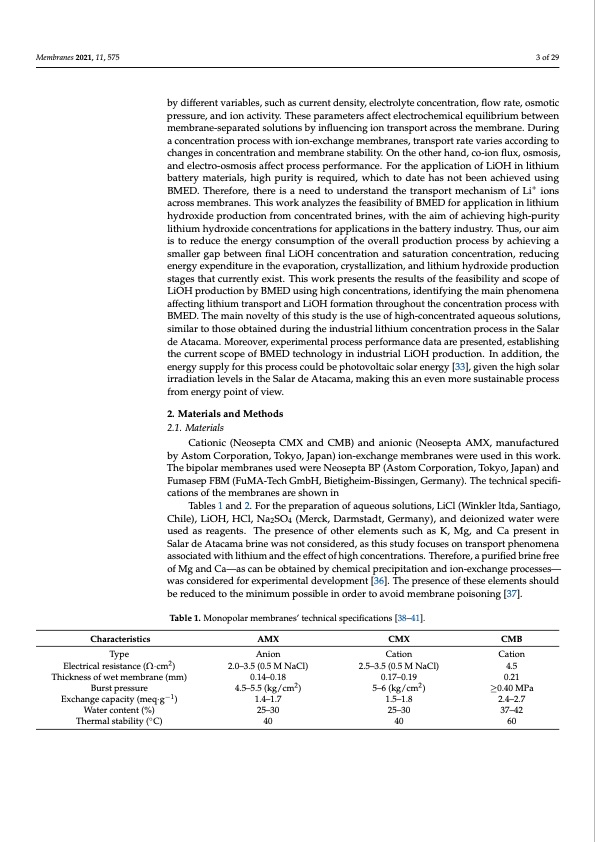

Membranes 2021, 11, 575 3 of 29 by different variables, such as current density, electrolyte concentration, flow rate, osmotic pressure, and ion activity. These parameters affect electrochemical equilibrium between membrane-separated solutions by influencing ion transport across the membrane. During a concentration process with ion-exchange membranes, transport rate varies according to changes in concentration and membrane stability. On the other hand, co-ion flux, osmosis, and electro-osmosis affect process performance. For the application of LiOH in lithium battery materials, high purity is required, which to date has not been achieved using BMED. Therefore, there is a need to understand the transport mechanism of Li+ ions across membranes. This work analyzes the feasibility of BMED for application in lithium hydroxide production from concentrated brines, with the aim of achieving high-purity lithium hydroxide concentrations for applications in the battery industry. Thus, our aim is to reduce the energy consumption of the overall production process by achieving a smaller gap between final LiOH concentration and saturation concentration, reducing energy expenditure in the evaporation, crystallization, and lithium hydroxide production stages that currently exist. This work presents the results of the feasibility and scope of LiOH production by BMED using high concentrations, identifying the main phenomena affecting lithium transport and LiOH formation throughout the concentration process with BMED. The main novelty of this study is the use of high-concentrated aqueous solutions, similar to those obtained during the industrial lithium concentration process in the Salar de Atacama. Moreover, experimental process performance data are presented, establishing the current scope of BMED technology in industrial LiOH production. In addition, the energy supply for this process could be photovoltaic solar energy [33], given the high solar irradiation levels in the Salar de Atacama, making this an even more sustainable process from energy point of view. 2. Materials and Methods 2.1. Materials Cationic (Neosepta CMX and CMB) and anionic (Neosepta AMX, manufactured by Astom Corporation, Tokyo, Japan) ion-exchange membranes were used in this work. The bipolar membranes used were Neosepta BP (Astom Corporation, Tokyo, Japan) and Fumasep FBM (FuMA-Tech GmbH, Bietigheim-Bissingen, Germany). The technical specifi- cations of the membranes are shown in Tables 1 and 2. For the preparation of aqueous solutions, LiCl (Winkler ltda, Santiago, Chile), LiOH, HCl, Na2SO4 (Merck, Darmstadt, Germany), and deionized water were used as reagents. The presence of other elements such as K, Mg, and Ca present in Salar de Atacama brine was not considered, as this study focuses on transport phenomena associated with lithium and the effect of high concentrations. Therefore, a purified brine free of Mg and Ca—as can be obtained by chemical precipitation and ion-exchange processes— was considered for experimental development [36]. The presence of these elements should be reduced to the minimum possible in order to avoid membrane poisoning [37]. Table 1. Monopolar membranes’ technical specifications [38–41]. Characteristics Type Electrical resistance (Ω·cm2) Thickness of wet membrane (mm) Burst pressure Exchange capacity (meq·g−1) Water content (%) Thermal stability (◦C) AMX Anion 2.0–3.5 (0.5 M NaCl) 0.14–0.18 4.5–5.5 (kg/cm2) 1.4–1.7 25–30 40 CMX Cation 2.5–3.5 (0.5 M NaCl) 0.17–0.19 5–6 (kg/cm2) 1.5–1.8 25–30 40 CMB Cation 4.5 0.21 ≥0.40 MPa 2.4–2.7 37–42 60PDF Image | Bipolar Membrane Electrodialysis for LiOH Production

PDF Search Title:

Bipolar Membrane Electrodialysis for LiOH ProductionOriginal File Name Searched:

membranes-11-00575-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |