PDF Publication Title:

Text from PDF Page: 004

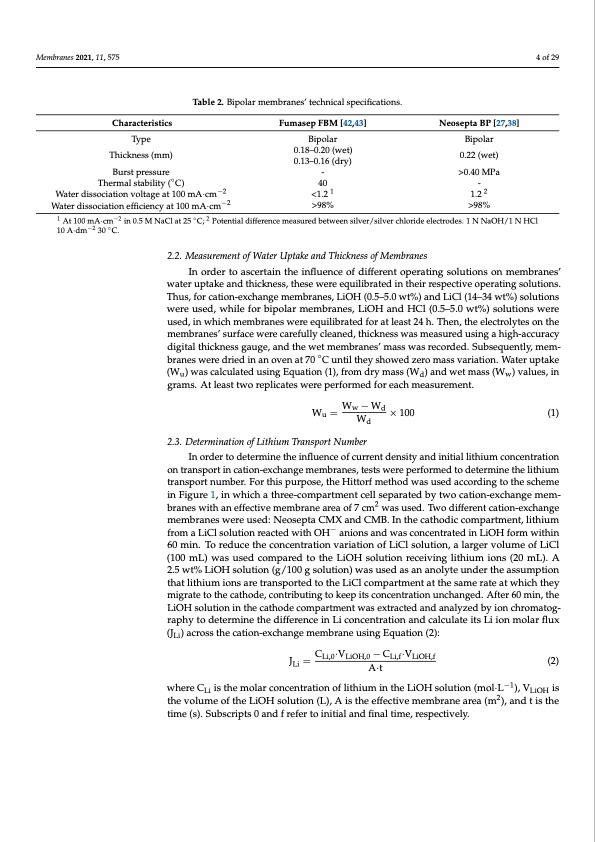

Membranes 2021, 11, 575 4 of 29 Table 2. Bipolar membranes’ technical specifications. Fumasep FBM [42,43] Characteristics Type Thickness (mm) Burst pressure Thermal stability (◦C) Water dissociation voltage at 100 mA·cm−2 Water dissociation efficiency at 100 mA·cm−2 Bipolar 0.18–0.20 (wet) 0.13–0.16 (dry) - 40 <1.2 1 >98% Neosepta BP [27,38] Bipolar 0.22 (wet) >0.40 MPa - 1.2 2 >98% 1 At 100 mA·cm−2 in 0.5 M NaCl at 25 ◦C; 2 Potential difference measured between silver/silver chloride electrodes. 1 N NaOH/1 N HCl 10 A·dm−2 30 ◦C. 2.2. Measurement of Water Uptake and Thickness of Membranes In order to ascertain the influence of different operating solutions on membranes’ water uptake and thickness, these were equilibrated in their respective operating solutions. Thus, for cation-exchange membranes, LiOH (0.5–5.0 wt%) and LiCl (14–34 wt%) solutions were used, while for bipolar membranes, LiOH and HCl (0.5–5.0 wt%) solutions were used, in which membranes were equilibrated for at least 24 h. Then, the electrolytes on the membranes’ surface were carefully cleaned, thickness was measured using a high-accuracy digital thickness gauge, and the wet membranes’ mass was recorded. Subsequently, mem- branes were dried in an oven at 70 ◦C until they showed zero mass variation. Water uptake (Wu) was calculated using Equation (1), from dry mass (Wd) and wet mass (Ww) values, in grams. At least two replicates were performed for each measurement. Wu = Ww −Wd ×100 (1) Wd 2.3. Determination of Lithium Transport Number In order to determine the influence of current density and initial lithium concentration on transport in cation-exchange membranes, tests were performed to determine the lithium transport number. For this purpose, the Hittorf method was used according to the scheme in Figure 1, in which a three-compartment cell separated by two cation-exchange mem- branes with an effective membrane area of 7 cm2 was used. Two different cation-exchange membranes were used: Neosepta CMX and CMB. In the cathodic compartment, lithium from a LiCl solution reacted with OH− anions and was concentrated in LiOH form within 60 min. To reduce the concentration variation of LiCl solution, a larger volume of LiCl (100 mL) was used compared to the LiOH solution receiving lithium ions (20 mL). A 2.5 wt% LiOH solution (g/100 g solution) was used as an anolyte under the assumption that lithium ions are transported to the LiCl compartment at the same rate at which they migrate to the cathode, contributing to keep its concentration unchanged. After 60 min, the LiOH solution in the cathode compartment was extracted and analyzed by ion chromatog- raphy to determine the difference in Li concentration and calculate its Li ion molar flux (JLi) across the cation-exchange membrane using Equation (2): JLi = CLi,0·VLiOH,0 − CLi,f·VLiOH,f (2) A·t where CLi is the molar concentration of lithium in the LiOH solution (mol·L−1), VLiOH is the volume of the LiOH solution (L), A is the effective membrane area (m2), and t is the time (s). Subscripts 0 and f refer to initial and final time, respectively.PDF Image | Bipolar Membrane Electrodialysis for LiOH Production

PDF Search Title:

Bipolar Membrane Electrodialysis for LiOH ProductionOriginal File Name Searched:

membranes-11-00575-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |