PDF Publication Title:

Text from PDF Page: 009

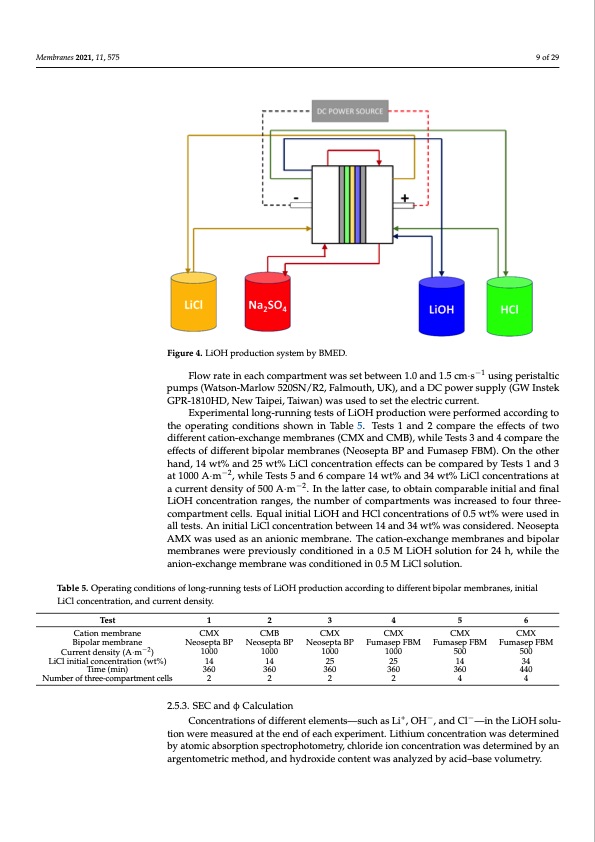

Membranes 2021, 11, 575 9 of 29 Membranes 2021, 11, x FOR PEER REVIEW 9 o Figure 4. LiOH production system by BMED. Figure 4. LiOH production system by BMED. Flow rate in each compartment was set between 1.0 and 1.5 cm·s−1 using peristaltic Experimental long-running tests of LiOH production were performed accordin pumps (Watson-Marlow 520SN/R2, Falmouth, UK), and a DC power supply (GW Instek the operating conditions shown in Table 5. Tests 1 and 2 compare the effects of two GPR-1810HD, New Taipei, Taiwan) was used to set the electric current. ferent cation-exchange membranes (CMX and CMB), while Tests 3 and 4 compare the Experimental long-running tests of LiOH production were performed according to fects of different bipolar membranes (Neosepta BP and Fumasep FBM). On the other ha the operating conditions shown in Table 5. Tests 1 and 2 compare the effects of two 14 wt% and 25 wt% LiCl concentration effects can be compared by Tests 1 and 3 at 1 different cation-exchange membranes (CMX and CMB), while Tests 3 and 4 compare the A∙m−2, while Tests 5 and 6 compare 14 wt% and 34 wt% LiCl concentrations at a curr effects of different bipolar membranes (Neosepta BP and Fumasep FBM). On the other density of 500 A∙m−2. In the latter case, to obtain comparable initial and final LiOH c hand, 14 wt% and 25 wt% LiCl concentration effects can be compared by Tests 1 and 3 centration ranges, the number of compartments was increased to four three-compartm at 1000 A·m−2, while Tests 5 and 6 compare 14 wt% and 34 wt% LiCl concentrations at cells. Equal initial−L2iOH and HCl concentrations of 0.5 wt% were used in all tests. a current density of 500 A·m . In the latter case, to obtain comparable initial and final initial LiCl concentration between 14 and 34 wt% was considered. Neosepta AMX LiOH concentration ranges, the number of compartments was increased to four three- used as an anionic membrane. The cation-exchange membranes and bipolar membra compartment cells. Equal initial LiOH and HCl concentrations of 0.5 wt% were used in were previously conditioned in a 0.5 M LiOH solution for 24 h, while the anion-excha all tests. An initial LiCl concentration between 14 and 34 wt% was considered. Neosepta membrane was conditioned in 0.5 M LiCl solution. AMX was used as an anionic membrane. The cation-exchange membranes and bipolar membranes were previously conditioned in a 0.5 M LiOH solution for 24 h, while the Table 5. Operating conditions of long-running tests of LiOH production according to different bipolar membranes, initial anion-exchange membrane was conditioned in 0.5 M LiCl solution. LiCl concentration, and current density. Table 5. Operating conditions of long-running tests of LiOH production according to different bipolar membranes, initial Test 123456 LiCl concentration, and current density. Cation membrane CMX CMB CMX CMX CMX CMX Bipolar membrane Neosepta BPNeosepta BPNeosepta BPFumasep FBMFumasep FBMFumasep F Test 123456 CMX CMX Number of three-compartment cells 2 2 2 2 4 4 4 Current density Cation membrane CMX Bipolar membrane (A∙m−2) Neosepta BP CMB CMX CMX Current density (A·m−2) 1000 LiCl initial concentration (wt%) Fumasep FBM LiCl initial concentration (wt%) 14 Time (min) 360 14 360 25 25 360 360 360 34 440 Time (min) 360 360 360 360 440 Number of three-compartment cells 2 1000 1000 1000 1000 500 500 Neosepta BP 1000 Neosepta BP 1000 1000 Fumasep FBM Fumasep FBM 500 14 14 4 14 34 2 2 2.5.3. SEC and Calculation 14 25 25 360 2 500 2.5.3. SEC and φ Calculation + − Concentrations of different elements—such as Li , OH , and Cl —in the LiOH solu- Concentrations of different elements—such as Li+, OH−, and Cl−—in the LiOH so tion were measured at the end of each experiment. Lithium concentration was determined tion were measured at the end of each experiment. Lithium concentration was determi by atomic absorption spectrophotometry, chloride ion concentration was determined by an by atomic absorption spectrophotometry, chloride ion concentration was determined argentometric method, and hydroxide content was analyzed by acid–base volumetry. an argentometric method, and hydroxide content was analyzed by acid–base volumet − f g d n 0 e o e A w n n B n rPDF Image | Bipolar Membrane Electrodialysis for LiOH Production

PDF Search Title:

Bipolar Membrane Electrodialysis for LiOH ProductionOriginal File Name Searched:

membranes-11-00575-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |